- 20

- Dec

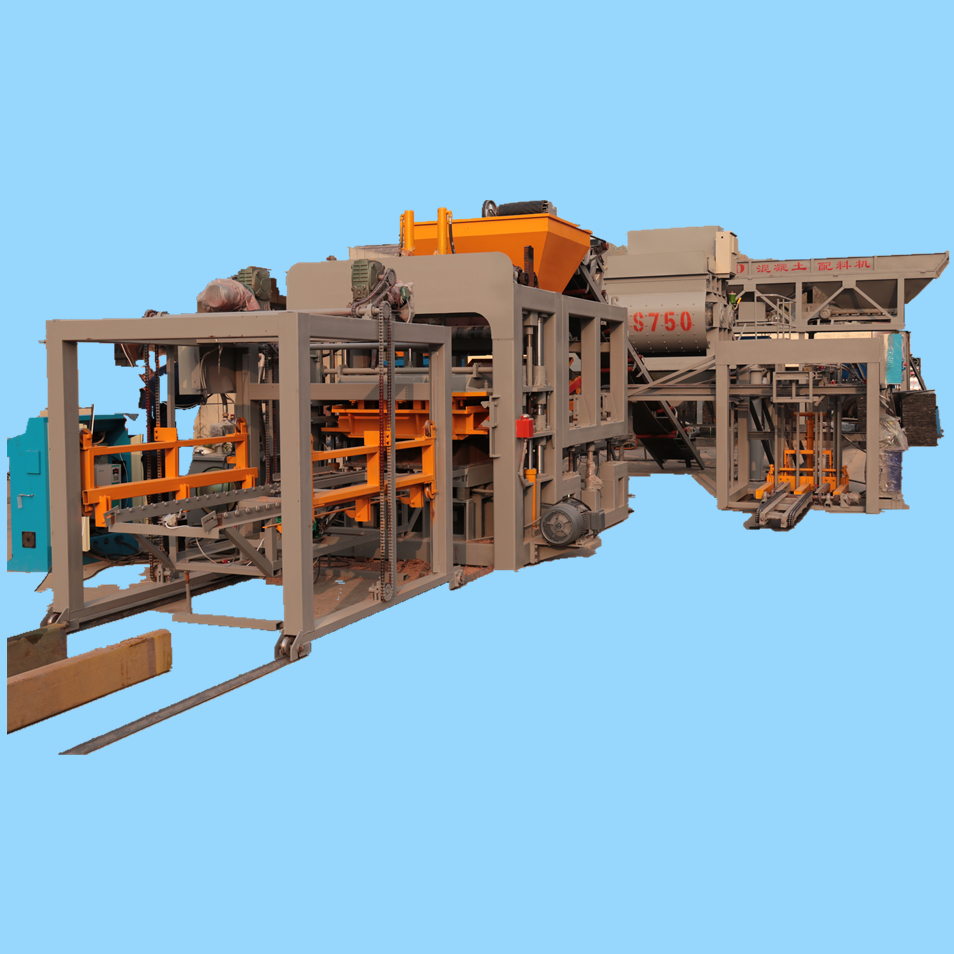

batch block machine

Our batch block machine are designed with efficiency, durability and versatility in mind. They can produce blocks in a variety of shapes and sizes, including standard Stamped concrete blocks, interlocking paving stones and hollow blocks. They are also highly customizable to meet specific production requirements and blocks can be produced quickly, saving time and labor.

These block making machines are ideal for both small and large scale production and are suitable for a variety of applications including Farm and agricultural building construction, road paving, landscaping and more. We also provide excellent after-sales support, with spare parts readily available and technical support for any maintenance or technical issues.

Equipped with a sturdy steel frame and a powerful motor, our block making machines can easily produce up to 10328 of blocks per hour, saving you time and labor costs. It has a versatile mold configuration that can manufacture a variety of block types and sizes, from standard Stamped concrete blocks to interlocking and Farm and agricultural building construction.

One of the popular models is the QT4-15 batch block machine, which has a production capacity of 800-1070 blocks per hour. It is equipped with an automatic control system and hydraulic components, making it easy to operate and maintain. The machine is also designed with a vibrating system, ensuring the even distribution of materials for consistent block quality. Its compact design allows for space-saving installation, making it suitable for both small and large scale production.

In terms of parameters, the QT4-15 batch block machine can produce standard bricks, hollow blocks, and other custom shapes with adjustable mold height and vibration frequency. It also has a hopper size of 800x800mm and a conveyor belt for efficient material feeding. Additionally, it has a power output of 24.5kw, ensuring high production speed and energy efficiency.

| land area | 344 Square Meters | Water Consumption | 2.4 T/day |

| Workshop area | 85 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 3 workers | Power Consumption | 26.5 KW*8 Hours=212 KWH; |

| Cement Consumption | 6.18 Tons per day | Sand consumption | 27.9 tons per day |

| Crushed stones consumption | 39.12 tons per day |

The Time-Saving Features of Modern Block Machines

batch block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.How does the cost of a batch block machine compare to traditional building materials?

3.About batch block machine payment method

4.How does a batch block machine handle different types of soils?

5.Can a batch block machine be connected to other construction equipment for seamless production?

6.Are there pre-programmed block designs available for a batch block machine?

7.Is there a specific curing process for blocks produced by a batch block machine?

8.What is a batch block machine?

9.Can a batch block machine be used for multiple types of construction projects?

10.Can a batch block machine produce blocks of varying shapes?

11.How does the weight of a block affect transportation and storage?

12.About batch block machine MOQ

13.About the scale of batch block machine factory

14.Are there any safety features built into the design of a batch block machine?

1.How does a batch block machine deal with unwanted air pockets in the blocks?

A block machine typically has a vibration system that helps to remove any unwanted air pockets in the blocks. The vibration system helps to compact the material and fill any voids that may be present. The vibration system also helps to ensure that the blocks are of a consistent density and strength.

2.How does the cost of a batch block machine compare to traditional building materials?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

The cost of a block machine is typically much higher than traditional building materials. Block machines are typically used to produce large quantities of blocks, which can be expensive to purchase in bulk. Additionally, block machines require specialized equipment and expertise to operate, which can add to the cost.

3.About batch block machine payment method

Block machine payment methods vary depending on the manufacturer and the type of machine. Some common payment methods include cash, credit cards, PayPal, wire transfers, and cryptocurrency. Some manufacturers may also offer financing options or leasing options.

4.How does a batch block machine handle different types of soils?

A block machine is designed to handle a variety of soils, including clay, sand, gravel, and other aggregates. Depending on the type of soil, the machine may need to be adjusted to ensure the blocks are formed correctly. For example, if the soil is clay-based, the machine may need to be adjusted to increase the pressure and vibration to ensure the blocks are formed correctly. Additionally, the machine may need to be adjusted to ensure the blocks are formed with the correct amount of moisture.

5.Can a batch block machine be connected to other construction equipment for seamless production?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

Yes, a block machine can be connected to other construction equipment for seamless production. This is done by using a conveyor system to move the blocks from the block machine to other construction equipment, such as a mixer, for further processing. This allows for a more efficient and automated production process.

6.Are there pre-programmed block designs available for a batch block machine?

We operate our batch block machine business with integrity and honesty.

Yes, some block machines come with pre-programmed block designs. However, many block machines also allow users to create their own custom designs.

7.Is there a specific curing process for blocks produced by a batch block machine?

Yes, there is a specific curing process for blocks produced by a block machine. The curing process typically involves keeping the blocks in a moist environment for a period of time, usually between 7 and 28 days. This allows the blocks to dry slowly and evenly, which helps to ensure that they are strong and durable.

8.What is a batch block machine?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

A block machine is a machine used to produce concrete blocks, which are used in the construction of walls, foundations, and other structures. The machine typically consists of a hopper, a conveyor belt, a mold, and a vibration table. The hopper is used to feed the concrete mix into the machine, the conveyor belt transports the mix to the mold, and the vibration table vibrates the mix to ensure a uniform block.

9.Can a batch block machine be used for multiple types of construction projects?

We have established a good reputation and reliable partnerships within the batch block machine industry.

Yes, a block machine can be used for multiple types of construction projects. Block machines are versatile and can be used to produce a variety of concrete blocks, including hollow blocks, paving blocks, curbstones, and more. They can also be used to produce other concrete products such as pavers, tiles, and slabs.

10.Can a batch block machine produce blocks of varying shapes?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, a block machine can produce blocks of varying shapes. Block machines are designed to produce blocks of different sizes and shapes, depending on the type of block machine and the type of block being produced. Some block machines are capable of producing blocks with complex shapes, such as interlocking blocks, while others are limited to producing blocks with basic shapes, such as rectangular blocks.

11.How does the weight of a block affect transportation and storage?

The weight of a block affects transportation and storage in several ways. Heavier blocks require more energy to move and can be more difficult to transport. They also require more space for storage, as they take up more room than lighter blocks. Additionally, heavier blocks may require more specialized equipment for transportation and storage, such as forklifts or cranes.

12.About batch block machine MOQ

The minimum order quantity (MOQ) for a block machine will vary depending on the type of machine and the manufacturer. Generally, the MOQ for a block machine is one unit. However, some manufacturers may require a minimum order of multiple units.

13.About the scale of batch block machine factory

The scale of a block machine factory can vary greatly depending on the type of block machine being produced. Some factories may only produce a few machines, while others may produce hundreds or even thousands of machines. The size of the factory will also depend on the size of the blocks being produced, as well as the number of machines needed to produce them.

14.Are there any safety features built into the design of a batch block machine?

Yes, there are several safety features built into the design of a block machine. These include emergency stop buttons, safety guards, and interlocks to prevent accidental operation. Additionally, many block machines are designed with a low center of gravity to reduce the risk of tipping over.