- 21

- Dec

ibm 1000 block machine price

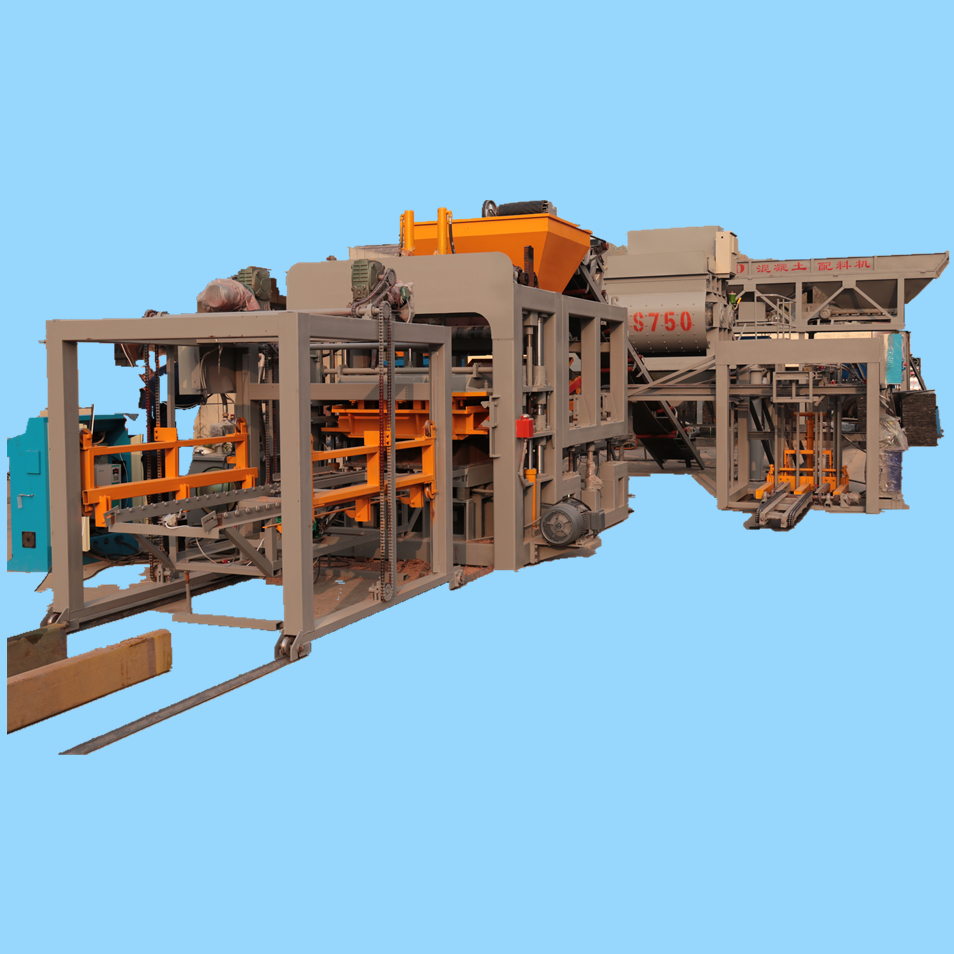

ibm 1000 block machine price is an innovative and high-quality construction machinery designed to produce blocks or bricks from various raw materials such as cement, sand, gravel, stone powder, Roadside blocks and more. It is widely used in the construction industry for building walls, pavements, and other structures.

This machine is equipped with advanced technology and components that ensure efficient and precise block production. It operates through a hydraulic system, which provides a consistent and smooth movement of the machine, resulting in higher production rates and excellent block quality.

Block Machine Technical Parameters:

1. Production capacity: up to 11077 blocks per hour

2. Mold configuration: customizable for different block types and sizes

3. Control panel: user-friendly interface for block thickness and density adjustments

4. Hydraulic system: ensures consistent and stable pressure

5. Service life: at least 10 years

6. Energy efficiency: minimal power consumption

7. Installation and training: turnkey package provided by our experts

The ibm 1000 block machine price comes in various models and configurations. Some popular models include the QMJ4-35A, QT4-15, and QT6-15. These machines are designed for different production capacities and can produce a range of concrete blocks such as hollow blocks, solid blocks, and paving blocks.

The QMJ4-35A is a manual model with a production capacity of 2964-3000 blocks per day. It has a power of 9.7 kW and can produce blocks in various sizes with a maximum length of 390mm. The QT4-15 is a semi-automatic model with a production capacity of 4000-7311 blocks per day. It is equipped with a 21.5 kW power and can produce blocks in different sizes up to 390mm in length. The QT6-15 is a fully automatic model with a production capacity of 8770-10000 blocks per day. It has a power of 27.5 kW and can produce blocks in various sizes up to 480mm in length.

| (1) | Dimension of host machine | 3115*2000*2000mm | (6) | labour | 4 workers |

| (2) | Weight of the host machine | 3.2T | (7) | Voltage | customized |

| (3) | Moulding period | 25-28 | (8) | Total required machine power | 26.5 KW |

| (4) | pallet size | 850*550*20mm | (9) | Diesel Generator capacity | 37.13KVA |

| (5) | Vibration force | 72KN | (10) | workshop area | 477 m2 |

Block Machines Redefining Building Standards

ibm 1000 block machine price FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.Can a ibm 1000 block machine price be used for both indoor and outdoor construction projects?

3.About ibm 1000 block machine price customization services

4.How does a ibm 1000 block machine price work?

5.How does the cost of a ibm 1000 block machine price compare to traditional building materials?

6.How is the weight of a block determined during production?

7.Is a ibm 1000 block machine price easy to operate?

8.About ibm 1000 block machine price quality system

9.Can a ibm 1000 block machine price produce blocks of varying shapes?

10.Can a ibm 1000 block machine price be operated remotely?

11.Can a ibm 1000 block machine price be operated continuously or does it require breaks?

12.What is the cost-effectiveness of using a ibm 1000 block machine price?

13.What are the maintenance costs associated with running a ibm 1000 block machine price?

14.Are there any special requirements for maintenance and storage of a ibm 1000 block machine price?

15.About ibm 1000 block machine price production equipment

16.Can a ibm 1000 block machine price be used in areas with limited access to electricity?

1.What materials are commonly used in a ibm 1000 block machine price?

Our mission is to provide customers with the best solutions for ibm 1000 block machine price.

Common materials used in block machines include concrete, sand, gravel, cement, and water. Depending on the type of block being made, other materials such as steel, plastic, and wood may also be used.

2.Can a ibm 1000 block machine price be used for both indoor and outdoor construction projects?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

Yes, a block machine can be used for both indoor and outdoor construction projects. However, the type of block machine used will depend on the specific project requirements. For example, a block machine designed for outdoor projects may be more powerful and durable than one designed for indoor projects.

3.About ibm 1000 block machine price customization services

Block machine customization services are designed to help businesses create custom-made block machines that are tailored to their specific needs. These services can include the design and engineering of the machine, the fabrication of the components, and the installation and maintenance of the machine. The customization services can also include the development of software and hardware to control the machine, as well as the integration of the machine into existing production lines. The customization services can also include the development of custom-made parts and components for the machine, as well as the development of custom-made tools and fixtures for the machine.

4.How does a ibm 1000 block machine price work?

We continuously upgrade our skills and knowledge to adapt to changing ibm 1000 block machine price market needs.

A block machine is a machine used to produce concrete blocks for use in construction projects. The machine works by using a combination of vibration, pressure, and heat to form the blocks. The blocks are formed in a mold, which is filled with a mixture of sand, cement, and water. The mold is then placed in the block machine, which vibrates and applies pressure to the mixture to form the blocks. The blocks are then removed from the mold and allowed to dry before being used in construction projects.

5.How does the cost of a ibm 1000 block machine price compare to traditional building materials?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

The cost of a block machine is typically much higher than traditional building materials. Block machines are typically used to produce large quantities of blocks, which can be expensive to purchase in bulk. Additionally, block machines require specialized equipment and expertise to operate, which can add to the cost.

6.How is the weight of a block determined during production?

Our ibm 1000 block machine price products undergo strict quality control to ensure customer satisfaction.

The weight of a block during production is typically determined by a combination of automated and manual processes. Automated processes may include weighing the block on a scale or using a computer-controlled system to measure the weight. Manual processes may include using a hand-held scale or a balance beam.

7.Is a ibm 1000 block machine price easy to operate?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

Yes, most block machines are designed to be easy to operate. Many modern block machines are automated and require minimal operator input. However, some block machines may require more operator input and knowledge to operate correctly.

8.About ibm 1000 block machine price quality system

A block machine quality system is a set of procedures and processes that are used to ensure that the block machines manufactured by a company meet the highest standards of quality. The system includes the use of quality control measures such as inspections, testing, and documentation to ensure that the block machines are safe and reliable. The system also includes the use of quality assurance measures such as training, auditing, and corrective action plans to ensure that the block machines are consistently meeting the required standards. The system also includes the use of preventive maintenance measures such as regular maintenance and repairs to ensure that the block machines are operating at peak efficiency.

9.Can a ibm 1000 block machine price produce blocks of varying shapes?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, a block machine can produce blocks of varying shapes. Block machines are designed to produce blocks of different sizes and shapes, depending on the type of block machine and the type of block being produced. Some block machines are capable of producing blocks with complex shapes, such as interlocking blocks, while others are limited to producing blocks with basic shapes, such as rectangular blocks.

10.Can a ibm 1000 block machine price be operated remotely?

Yes, some block machines can be operated remotely. This is usually done through a computer or mobile device, and the machine can be programmed to run automatically.

11.Can a ibm 1000 block machine price be operated continuously or does it require breaks?

Yes, a block machine can be operated continuously, but it is recommended to give it regular breaks to allow for maintenance and repairs.

12.What is the cost-effectiveness of using a ibm 1000 block machine price?

The cost-effectiveness of using a block machine depends on the type of block machine being used, the size of the project, and the amount of labor required. Generally, block machines are more cost-effective than traditional methods of block production, as they require less labor and can produce more blocks in a shorter amount of time. Additionally, block machines can produce blocks with a higher degree of accuracy and uniformity than traditional methods, which can result in a higher quality product.

13.What are the maintenance costs associated with running a ibm 1000 block machine price?

The maintenance costs associated with running a Block machine will vary depending on the type of machine and its age. Generally, maintenance costs can include regular oil changes, filter replacements, lubrication, and other routine maintenance. Additionally, more complex repairs such as replacing worn parts or repairing electrical components may be necessary. Depending on the machine, these repairs can be costly.

14.Are there any special requirements for maintenance and storage of a ibm 1000 block machine price?

Our company has many years of ibm 1000 block machine price experience and expertise.

Yes, there are special requirements for maintenance and storage of a block machine. It is important to keep the machine clean and free of debris, as well as to lubricate all moving parts regularly. Additionally, the machine should be stored in a dry, dust-free environment and away from direct sunlight.

15.About ibm 1000 block machine price production equipment

Block machine production equipment is used to produce concrete blocks, bricks, and other masonry products. This equipment typically includes a mixer, a block machine, a conveyor, and a curing chamber. The mixer is used to mix the concrete, while the block machine is used to form the blocks. The conveyor is used to move the blocks to the curing chamber, where they are cured and hardened. The equipment is typically powered by electricity or diesel fuel.

16.Can a ibm 1000 block machine price be used in areas with limited access to electricity?

We are a professional ibm 1000 block machine price company dedicated to providing high quality products and services.

Yes, some block machines can be used in areas with limited access to electricity. Some block machines are powered by diesel engines, which can be used in areas with limited access to electricity.