- 22

- Nov

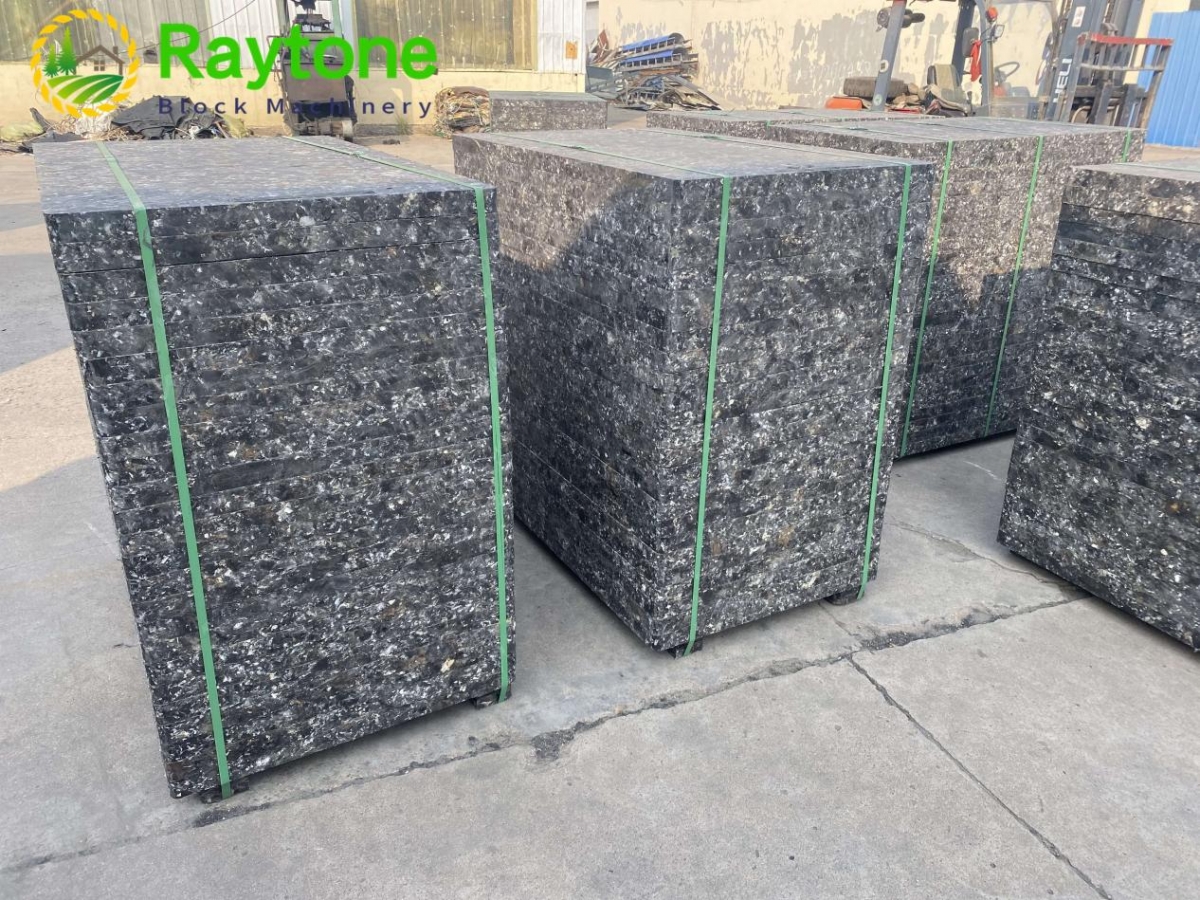

GMT pallet for block machine is shipped to IRAN in October 2023

GMT pallet for block machine is shipped to IRAN

The GMT Brick Pallet is most common pallet used pallet in the block machine industry now; the Iran client Ms. Emmami came to Raytone company for brick pallet inquiry in May of 2023, after we confirmed the brick weight per pallet and quoted her the price, firstly she requires us to send some samples, then we arranged 10 pieces of 1240*750*45mm sample immediately, after one month time, the sample arrive at Ms. Emmami, after their test on the block machine, the pallet is performing very well, then she place us the order of one container quantity, we did the shipment on time in October.

Below we will give an introduction of the GMT brick pallet:

Introduction

In the world of block machine production, the choice of pallet plays a crucial role in ensuring efficiency, durability, and cost-effectiveness. One such pallet that has gained immense popularity is the Glass Fiber Mat Reinforced Thermoplastics (GMT) brick pallet. In this article, we will explore the characteristics, applications, advantages, and more of GMT brick pallets.

Characteristics of GMT Brick Pallets

GMT brick pallets are manufactured using a combination of glass fiber and thermoplastic resins. This unique composition gives them exceptional strength, rigidity, and dimensional stability. Some key characteristics of GMT brick pallets include:

Durability: GMT brick pallets are highly durable and can withstand heavy loads, impacts, and rough handling. They have a longer lifespan compared to traditional wooden or plastic pallets.

Dimensional Accuracy: GMT brick pallets are engineered to maintain their shape and dimensions over time, ensuring precise alignment during the block machine production process. This leads to consistent product quality and reduced wastage.

Moisture Resistance: Unlike wooden pallets, GMT brick pallets are resistant to moisture, preventing warping, rotting, and mold growth. This makes them suitable for both indoor and outdoor block machine operations.

Applications of GMT Brick Pallets

GMT brick pallets find extensive applications in the block machine industry. They are widely used in the production of concrete blocks, pavers, tiles, and other building materials. GMT brick pallets are compatible with various types of block machines, including hydraulic, semi-automatic, and fully automatic systems.

Advantages of GMT Brick Pallets

Increased Productivity: The superior strength and dimensional stability of GMT brick pallets allow for faster production cycles, reducing downtime and increasing overall productivity.

Cost Savings: GMT brick pallets offer significant cost savings in the long run. Their durability eliminates the need for frequent replacements, reducing maintenance costs and increasing operational efficiency.

Improved Product Quality: The dimensional accuracy of GMT brick pallets ensures consistent product dimensions and surface finish. This leads to higher-quality blocks with minimal variations.

Environmental Sustainability: GMT brick pallets are made from recycled materials, making them an eco-friendly alternative to traditional wooden pallets. Their recyclability further contributes to reducing waste and promoting sustainability.

Easy Handling and Maintenance: GMT brick pallets are lightweight yet robust, making them easy to handle and transport. They require minimal maintenance and can be cleaned effortlessly.

Conclusion

with its exceptional characteristics, applications, and advantages. From increased productivity and cost savings to improved product quality and environmental sustainability, GMT brick pallets have become a preferred choice for block machine manufacturers worldwide.