- 21

- Dec

tiger block machine

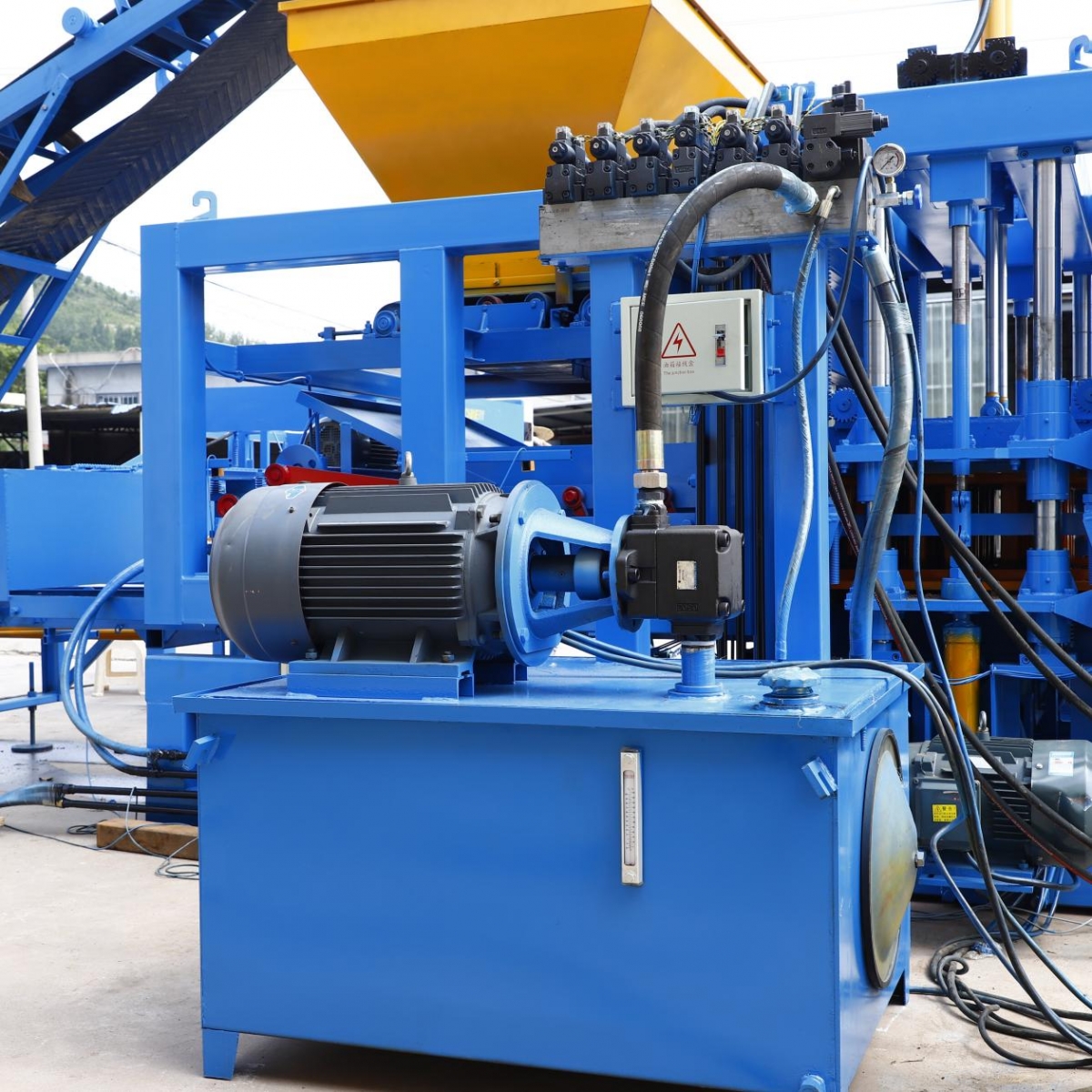

RAYTONE tiger block machine machine has a powerful hydraulic system and can produce Stone veneer blocks in various sizes and shapes, including standard blocks, hollow blocks and interlocking blocks. It has a sturdy and durable frame that ensures stable and consistent performance for long-term use. With its user-friendly interface and easy-to-operate control panel, the block machine can be produced and adjusted with ease. It has a capacity of up to 8727 blocks per day, making it suitable for large-scale production.

Our tiger block machine is available in various models and comes with a range of different parameters to cater to your specific needs. The models include the QMJ4-35, QTJ4-26C, QT5-15, and QT8-15, each offering unique features and capabilities.

The QMJ4-35 model is a small and compact machine, ideal for projects with limited space. It has a production capacity of 400 to $keyworrd{36} blocks per hour and a power consumption of 11.25 kW. The QTJ4-26C model is an upgraded version with a higher production capacity of 800 to 2295 blocks per hour and a lower power consumption of 9.6 kW.

For larger projects, the QT5-15 model is a perfect choice with a production capacity of 7385 to 8346 blocks per 8 hours, and a power consumption of 21 kW. It also comes with a hydraulic system for more efficient and precise operation. The QT8-15 model is our most advanced and largest model, with a production capacity of 9600 to 12000 blocks per 8 hours and a power consumption of 51 kW. It also has an intelligent PLC control system for automated operation.

In addition to these models, we offer various configurations for different block sizes and shapes, such as hollow blocks, solid blocks, and interlocking blocks. Our tiger block machine is also equipped with high-quality motors and hydraulic components for reliable and durable performance. With our customizable options and reliable technology, our tiger block machine is the perfect solution for all your block-making needs.

| land area | 339 Square Meters | Water Consumption | 2.4 T/day |

| Workshop area | 51 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 3 workers | Power Consumption | 26.5 KW*8 Hours=212 KWH; |

| Cement Consumption | 8.48 Tons per day | Sand consumption | 29.2 tons per day |

| Crushed stones consumption | 34.61 tons per day |

The Time-Saving Features of Modern Block Machines

tiger block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.What types of blocks can a tiger block machine produce?

3.Can a tiger block machine be used for multiple types of construction projects?

4.About tiger block machine overseas warehouse

5.Can a tiger block machine produce blocks with varying levels of compressive strength?

6.What is the expected return on investment for a tiger block machine?

7.Are there pre-programmed block designs available for a tiger block machine?

8.How does climate affect the production of blocks with a tiger block machine?

9.Are spare parts readily available for a tiger block machine?

10.About tiger block machine quality system

11.What are the maintenance costs associated with running a tiger block machine?

12.About tiger block machine payment method

1.What materials are commonly used in a tiger block machine?

Our mission is to provide customers with the best solutions for tiger block machine.

Common materials used in block machines include concrete, sand, gravel, cement, and water. Depending on the type of block being made, other materials such as steel, plastic, and wood may also be used.

2.What types of blocks can a tiger block machine produce?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

A block machine can produce a variety of blocks, including concrete blocks, cinder blocks, interlocking blocks, retaining wall blocks, and paving blocks.

3.Can a tiger block machine be used for multiple types of construction projects?

We have established a good reputation and reliable partnerships within the tiger block machine industry.

Yes, a block machine can be used for multiple types of construction projects. Block machines are versatile and can be used to produce a variety of concrete blocks, including hollow blocks, paving blocks, curbstones, and more. They can also be used to produce other concrete products such as pavers, tiles, and slabs.

4.About tiger block machine overseas warehouse

Block machine overseas warehouses are warehouses located in different countries around the world that store and distribute block machines. These warehouses are used to store and ship block machines to customers in different countries. The warehouses are typically owned and operated by the block machine manufacturer or distributor. They are responsible for ensuring that the block machines are properly stored and shipped to customers in a timely manner.

5.Can a tiger block machine produce blocks with varying levels of compressive strength?

Yes, a block machine can produce blocks with varying levels of compressive strength. This is done by adjusting the amount of pressure applied to the blocks during the manufacturing process. The amount of pressure applied can be adjusted to produce blocks with different levels of compressive strength.

6.What is the expected return on investment for a tiger block machine?

The expected return on investment for a block machine can vary greatly depending on the type of machine, the size of the project, and the market conditions. Generally, block machines can have a return on investment of anywhere from 10-30%, with some machines having returns as high as 50%.

7.Are there pre-programmed block designs available for a tiger block machine?

We operate our tiger block machine business with integrity and honesty.

Yes, some block machines come with pre-programmed block designs. However, many block machines also allow users to create their own custom designs.

8.How does climate affect the production of blocks with a tiger block machine?

As one of the top tiger block machine manufacturers in China, we take this very seriously.

Climate can affect the production of blocks with a block machine in a few ways. In cold climates, the concrete mix may need to be adjusted to ensure that it sets properly. In hot climates, the concrete mix may need to be adjusted to ensure that it does not set too quickly. Additionally, in hot climates, the block machine may need to be cooled to prevent overheating. Finally, in humid climates, the block machine may need to be equipped with a dehumidifier to prevent moisture from affecting the production process.

9.Are spare parts readily available for a tiger block machine?

tiger block machine is not a product only, but also can help you comes to money-making.

Yes, spare parts for block machines are readily available. Many manufacturers offer spare parts for their machines, and there are also third-party suppliers that offer spare parts for a variety of block machines.

10.About tiger block machine quality system

A block machine quality system is a set of procedures and processes that are used to ensure that the block machines manufactured by a company meet the highest standards of quality. The system includes the use of quality control measures such as inspections, testing, and documentation to ensure that the block machines are safe and reliable. The system also includes the use of quality assurance measures such as training, auditing, and corrective action plans to ensure that the block machines are consistently meeting the required standards. The system also includes the use of preventive maintenance measures such as regular maintenance and repairs to ensure that the block machines are operating at peak efficiency.

11.What are the maintenance costs associated with running a tiger block machine?

The maintenance costs associated with running a Block machine will vary depending on the type of machine and its age. Generally, maintenance costs can include regular oil changes, filter replacements, lubrication, and other routine maintenance. Additionally, more complex repairs such as replacing worn parts or repairing electrical components may be necessary. Depending on the machine, these repairs can be costly.

12.About tiger block machine payment method

Block machine payment methods vary depending on the manufacturer and the type of machine. Some common payment methods include cash, credit cards, PayPal, wire transfers, and cryptocurrency. Some manufacturers may also offer financing options or leasing options.