- 21

- 12月

hot sale concrete block machine

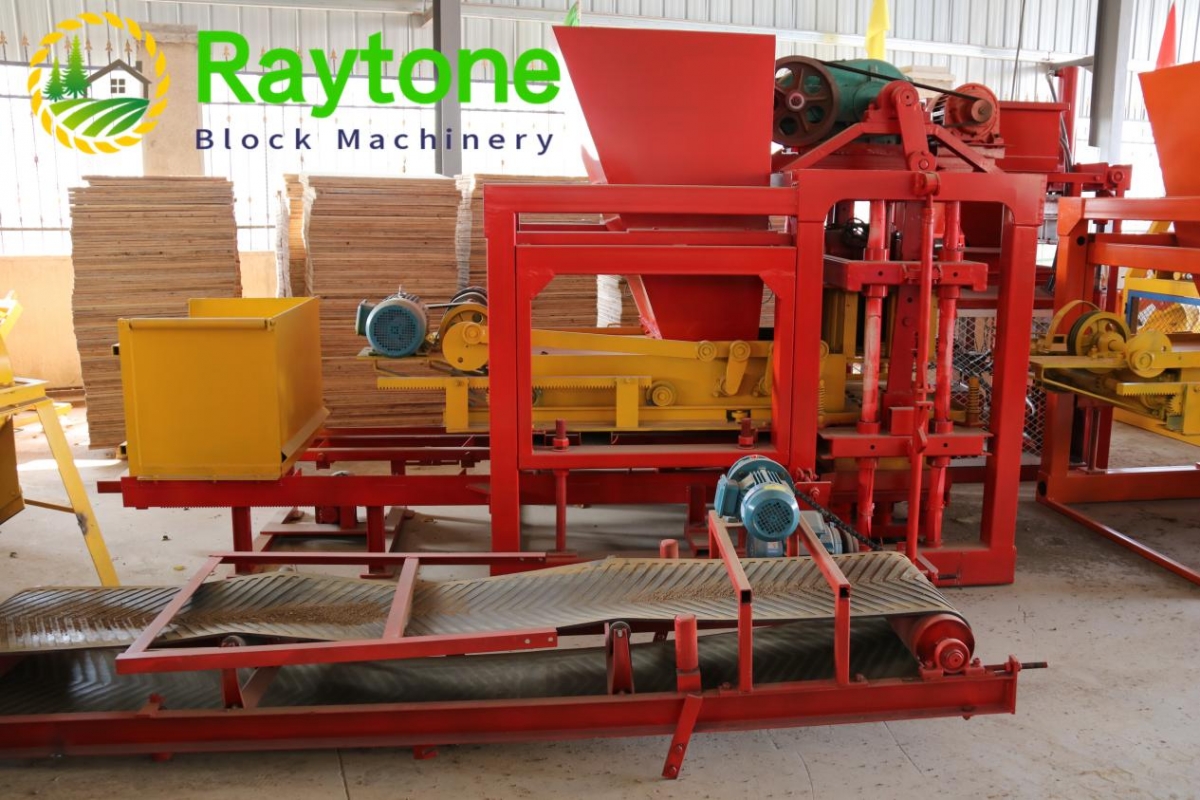

One of our signature products is the fully automatic hot sale concrete block machine, capable of producing different types of blocks, such as hollow blocks, solid blocks, Gabion blocksand paving blocks. This machine is highly automated, making it easy to operate and maintain while achieving a high output rate. It is also equipped with a pallet feeder, brick conveyor, and hydraulic system for efficient handling and production.

For those in need of a more versatile machine, we also offer the semi-automatic block machine, which allows for manual control and adjustment of operations. This machine is ideal for small-scale production and can produce various sizes and shapes of concrete blocks.

Equipped with a durable and robust frame, our hot sale concrete block machine is able to withstand heavy-duty usage and deliver consistent and high-quality results. The model comes in various configurations to cater to different productivity needs, with options for manual or automatic operation.

In terms of parameters, the Block Machine has a maximum pressure of 2995kN, and its vibration frequency can be adjusted from 0-93Hz. It can handle raw materials such as sand, cement, gravel, and fly ash, with a maximum particle size of 10mm. The machine’s power supply is customizable according to the customer’s requirements, and it has a low power consumption of 11.36 kW.

Furthermore, our hot sale concrete block machine is equipped with an advanced control system that ensures smooth and accurate operation. It also has a large hopper capacity, reducing the need for frequent refilling and increasing production efficiency.

| (1) | Dimension of host machine | 3176*2000*2000mm | (6) | labour | 4 workers |

| (2) | Weight of the host machine | 3.2T | (7) | Voltage | customized |

| (3) | Moulding period | 25-28 | (8) | Total required machine power | 26.5 KW |

| (4) | pallet size | 850*550*20mm | (9) | Diesel Generator capacity | 39.47KVA |

| (5) | Vibration force | 56KN | (10) | workshop area | 397 m2 |

Maximizing Structural Strength with Block Machines

hot sale concrete block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.Can a hot sale concrete block machine be used in cold weather conditions?

3.How does the weight of a block affect transportation and storage?

4.Can a hot sale concrete block machine be used for large scale production?

5.About hot sale concrete block machine production skills training

6.About hot sale concrete block machine patent

7.Can a hot sale concrete block machine be used for both indoor and outdoor construction projects?

8.Are there any noise or vibration concerns with a hot sale concrete block machine?

9.What is the cost-effectiveness of using a hot sale concrete block machine?

10.Can a hot sale concrete block machine be used to produce other building materials besides blocks?

11.Are there any environmental concerns related to the production of blocks with a hot sale concrete block machine?

12.About hot sale concrete block machine quality system

13.Is there a specific curing process for blocks produced by a hot sale concrete block machine?

14.About hot sale concrete block machine technology

1.Are there different levels of automation available for hot sale concrete block machines?

We operate our hot sale concrete block machine business with integrity and honesty.

Yes, there are different levels of automation available for block machines. Automation levels range from manual machines to fully automated machines. Manual machines require manual labor to operate, while fully automated machines are capable of producing blocks with minimal human intervention. Automation levels can also vary depending on the type of block machine being used.

2.Can a hot sale concrete block machine be used in cold weather conditions?

Yes, a block machine can be used in cold weather conditions. However, it is important to ensure that the machine is properly insulated and heated to prevent any damage from the cold temperatures. Additionally, it is important to ensure that the machine is properly lubricated and maintained to ensure that it is functioning properly in cold weather conditions.

3.How does the weight of a block affect transportation and storage?

The weight of a block affects transportation and storage in several ways. Heavier blocks require more energy to move and can be more difficult to transport. They also require more space for storage, as they take up more room than lighter blocks. Additionally, heavier blocks may require more specialized equipment for transportation and storage, such as forklifts or cranes.

4.Can a hot sale concrete block machine be used for large scale production?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, block machines can be used for large scale production. Block machines are designed to produce large quantities of concrete blocks in a short amount of time. They are typically used in the construction industry to produce blocks for walls, foundations, and other structures.

5.About hot sale concrete block machine production skills training

Block machine production skills training is a type of training that teaches individuals how to operate and maintain block machines. This type of training is important for those who are looking to start a business in the block machine industry. The training covers topics such as safety, operation, maintenance, troubleshooting, and more. It also provides hands-on experience with the machines so that individuals can gain a better understanding of how they work. This type of training is essential for anyone looking to start a business in the block machine industry.

6.About hot sale concrete block machine patent

Block machine patents are patents that cover the design and operation of machines used to make blocks of various materials, such as concrete, clay, and other masonry materials. These machines are used in the construction industry to create walls, foundations, and other structures. Block machine patents typically cover the design of the machine, the operation of the machine, and the materials used in the production of blocks.

7.Can a hot sale concrete block machine be used for both indoor and outdoor construction projects?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

Yes, a block machine can be used for both indoor and outdoor construction projects. However, the type of block machine used will depend on the specific project requirements. For example, a block machine designed for outdoor projects may be more powerful and durable than one designed for indoor projects.

8.Are there any noise or vibration concerns with a hot sale concrete block machine?

Yes, noise and vibration are common concerns with block machines. The noise and vibration levels can vary depending on the type of machine and the materials being used. It is important to ensure that the machine is properly maintained and that the operator is properly trained to reduce the risk of excessive noise and vibration.

9.What is the cost-effectiveness of using a hot sale concrete block machine?

The cost-effectiveness of using a block machine depends on the type of block machine being used, the size of the project, and the amount of labor required. Generally, block machines are more cost-effective than traditional methods of block production, as they require less labor and can produce more blocks in a shorter amount of time. Additionally, block machines can produce blocks with a higher degree of accuracy and uniformity than traditional methods, which can result in a higher quality product.

10.Can a hot sale concrete block machine be used to produce other building materials besides blocks?

Yes, a block machine can be used to produce other building materials such as pavers, bricks, tiles, and even roof tiles.

11.Are there any environmental concerns related to the production of blocks with a hot sale concrete block machine?

Yes, there are environmental concerns related to the production of blocks with a Block machine. The production of blocks with a Block machine can produce dust, noise, and air pollution. Additionally, the production of blocks with a Block machine can also lead to the depletion of natural resources, such as sand and gravel, which are used in the production process.

12.About hot sale concrete block machine quality system

A block machine quality system is a set of procedures and processes that are used to ensure that the block machines manufactured by a company meet the highest standards of quality. The system includes the use of quality control measures such as inspections, testing, and documentation to ensure that the block machines are safe and reliable. The system also includes the use of quality assurance measures such as training, auditing, and corrective action plans to ensure that the block machines are consistently meeting the required standards. The system also includes the use of preventive maintenance measures such as regular maintenance and repairs to ensure that the block machines are operating at peak efficiency.

13.Is there a specific curing process for blocks produced by a hot sale concrete block machine?

Yes, there is a specific curing process for blocks produced by a block machine. The curing process typically involves keeping the blocks in a moist environment for a period of time, usually between 7 and 28 days. This allows the blocks to dry slowly and evenly, which helps to ensure that they are strong and durable.

14.About hot sale concrete block machine technology

Block machine technology is a type of construction technology that is used to produce concrete blocks. It is a process that involves mixing cement, sand, and water to form a concrete mixture, which is then poured into a mold and compressed to form a block. The blocks are then cured and hardened before being used in construction projects. Block machine technology has been used for centuries to create strong and durable structures. It is a cost-effective and efficient way to build structures that are both aesthetically pleasing and structurally sound.