- 21

- 12月

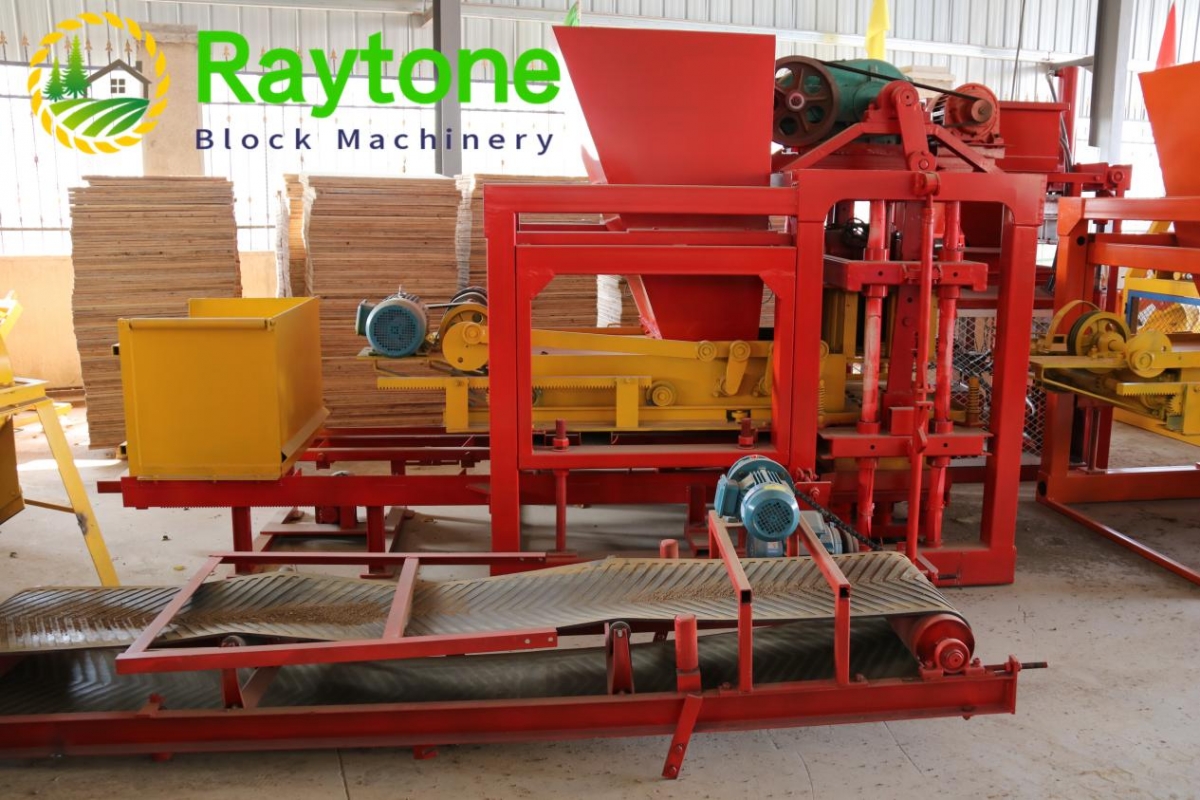

interlocking block machine

Our interlocking block machine are suitable for producing different types of blocks such as hollow, solid, Textured concrete blocks, and paving blocks. They utilize hydraulic pressure to compress raw materials such as sand, cement, and gravel to form strong and durable concrete blocks. The blocks produced by our machines have accurate dimensions, smooth surfaces, and can withstand high pressures, making them perfect for building walls, fences, Textured concrete blocks, and other structures.

Our interlocking block machine is available in various models and comes with a range of different parameters to cater to your specific needs. The models include the QMJ4-35, QTJ4-26C, QT5-15, and QT8-15, each offering unique features and capabilities.

The QMJ4-35 model is a small and compact machine, ideal for projects with limited space. It has a production capacity of 400 to $keyworrd{36} blocks per hour and a power consumption of 11.25 kW. The QTJ4-26C model is an upgraded version with a higher production capacity of 800 to 2519 blocks per hour and a lower power consumption of 9.6 kW.

For larger projects, the QT5-15 model is a perfect choice with a production capacity of 7401 to 8694 blocks per 8 hours, and a power consumption of 21 kW. It also comes with a hydraulic system for more efficient and precise operation. The QT8-15 model is our most advanced and largest model, with a production capacity of 9600 to 12000 blocks per 8 hours and a power consumption of 51 kW. It also has an intelligent PLC control system for automated operation.

In addition to these models, we offer various configurations for different block sizes and shapes, such as hollow blocks, solid blocks, and interlocking blocks. Our interlocking block machine is also equipped with high-quality motors and hydraulic components for reliable and durable performance. With our customizable options and reliable technology, our interlocking block machine is the perfect solution for all your block-making needs.

| land area | 338 Square Meters | Water Consumption | 2.4 T/day |

| Workshop area | 85 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 3 workers | Power Consumption | 26.5 KW*8 Hours=212 KWH; |

| Cement Consumption | 8.71 Tons per day | Sand consumption | 29.9 tons per day |

| Crushed stones consumption | 34.64 tons per day |

The Advantages of Block Machine Technology

interlocking block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.How does a interlocking block machine work?

3.About interlocking block machine patent

4.Are there any safety features built into the design of a interlocking block machine?

5.How is the quality of blocks produced by a interlocking block machine ensured?

6.What is the lifespan of a interlocking block machine?

7.Is there a specific curing process for blocks produced by a interlocking block machine?

8.Can a interlocking block machine be used for both indoor and outdoor construction projects?

9.About interlocking block machine production skills training

10.About interlocking block machine origin

11.What is the power source for a interlocking block machine?

12.How does a interlocking block machine deal with unwanted air pockets in the blocks?

13.About the scale of interlocking block machine factory

14.Can a interlocking block machine be used in areas with limited access to electricity?

15.How is the weight of a block determined during production?

16.What is the size and weight of a typical interlocking block machine?

1.Can a interlocking block machine be operated continuously or does it require breaks?

Yes, a block machine can be operated continuously, but it is recommended to give it regular breaks to allow for maintenance and repairs.

2.How does a interlocking block machine work?

We continuously upgrade our skills and knowledge to adapt to changing interlocking block machine market needs.

A block machine is a machine used to produce concrete blocks for use in construction projects. The machine works by using a combination of vibration, pressure, and heat to form the blocks. The blocks are formed in a mold, which is filled with a mixture of sand, cement, and water. The mold is then placed in the block machine, which vibrates and applies pressure to the mixture to form the blocks. The blocks are then removed from the mold and allowed to dry before being used in construction projects.

3.About interlocking block machine patent

Block machine patents are patents that cover the design and operation of machines used to make blocks of various materials, such as concrete, clay, and other masonry materials. These machines are used in the construction industry to create walls, foundations, and other structures. Block machine patents typically cover the design of the machine, the operation of the machine, and the materials used in the production of blocks.

4.Are there any safety features built into the design of a interlocking block machine?

Yes, there are several safety features built into the design of a block machine. These include emergency stop buttons, safety guards, and interlocks to prevent accidental operation. Additionally, many block machines are designed with a low center of gravity to reduce the risk of tipping over.

5.How is the quality of blocks produced by a interlocking block machine ensured?

The quality of blocks produced by a block machine is ensured by using high-quality raw materials, controlling the temperature and pressure of the machine, and using quality control measures such as testing the blocks for strength and durability. Additionally, the machine should be regularly serviced and maintained to ensure that it is operating correctly and producing blocks of the highest quality.

6.What is the lifespan of a interlocking block machine?

Our products & services cover a wide range of areas and meet the needs of different fields.

The lifespan of a block machine can vary depending on the type of machine and how it is used. Generally, block machines can last anywhere from 10 to 20 years with proper maintenance.

7.Is there a specific curing process for blocks produced by a interlocking block machine?

Yes, there is a specific curing process for blocks produced by a block machine. The curing process typically involves keeping the blocks in a moist environment for a period of time, usually between 7 and 28 days. This allows the blocks to dry slowly and evenly, which helps to ensure that they are strong and durable.

8.Can a interlocking block machine be used for both indoor and outdoor construction projects?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

Yes, a block machine can be used for both indoor and outdoor construction projects. However, the type of block machine used will depend on the specific project requirements. For example, a block machine designed for outdoor projects may be more powerful and durable than one designed for indoor projects.

9.About interlocking block machine production skills training

Block machine production skills training is a type of training that teaches individuals how to operate and maintain block machines. This type of training is important for those who are looking to start a business in the block machine industry. The training covers topics such as safety, operation, maintenance, troubleshooting, and more. It also provides hands-on experience with the machines so that individuals can gain a better understanding of how they work. This type of training is essential for anyone looking to start a business in the block machine industry.

10.About interlocking block machine origin

Block machine origin dates back to the late 19th century when the first concrete block machines were developed. The first machines were used to produce concrete blocks for the construction of buildings and other structures. The machines were developed to increase the speed and efficiency of the production process. Over the years, the technology has advanced and the machines have become more sophisticated and efficient. Today, block machines are used in a variety of industries, including construction, manufacturing, and mining.

11.What is the power source for a interlocking block machine?

Our products & services cover a wide range of areas and meet the needs of different fields.

The power source for a block machine is typically an electric motor. Some block machines may also be powered by a diesel engine.

12.How does a interlocking block machine deal with unwanted air pockets in the blocks?

A block machine typically has a vibration system that helps to remove any unwanted air pockets in the blocks. The vibration system helps to compact the material and fill any voids that may be present. The vibration system also helps to ensure that the blocks are of a consistent density and strength.

13.About the scale of interlocking block machine factory

The scale of a block machine factory can vary greatly depending on the type of block machine being produced. Some factories may only produce a few machines, while others may produce hundreds or even thousands of machines. The size of the factory will also depend on the size of the blocks being produced, as well as the number of machines needed to produce them.

14.Can a interlocking block machine be used in areas with limited access to electricity?

We are a professional interlocking block machine company dedicated to providing high quality products and services.

Yes, some block machines can be used in areas with limited access to electricity. Some block machines are powered by diesel engines, which can be used in areas with limited access to electricity.

15.How is the weight of a block determined during production?

Our interlocking block machine products undergo strict quality control to ensure customer satisfaction.

The weight of a block during production is typically determined by a combination of automated and manual processes. Automated processes may include weighing the block on a scale or using a computer-controlled system to measure the weight. Manual processes may include using a hand-held scale or a balance beam.

16.What is the size and weight of a typical interlocking block machine?

The size and weight of a typical block machine will vary depending on the type and model of the machine. Generally, block machines range in size from about 4 feet wide by 8 feet long to 8 feet wide by 20 feet long. The weight of a typical block machine can range from 1,000 to 10,000 pounds.