- 21

- 12月

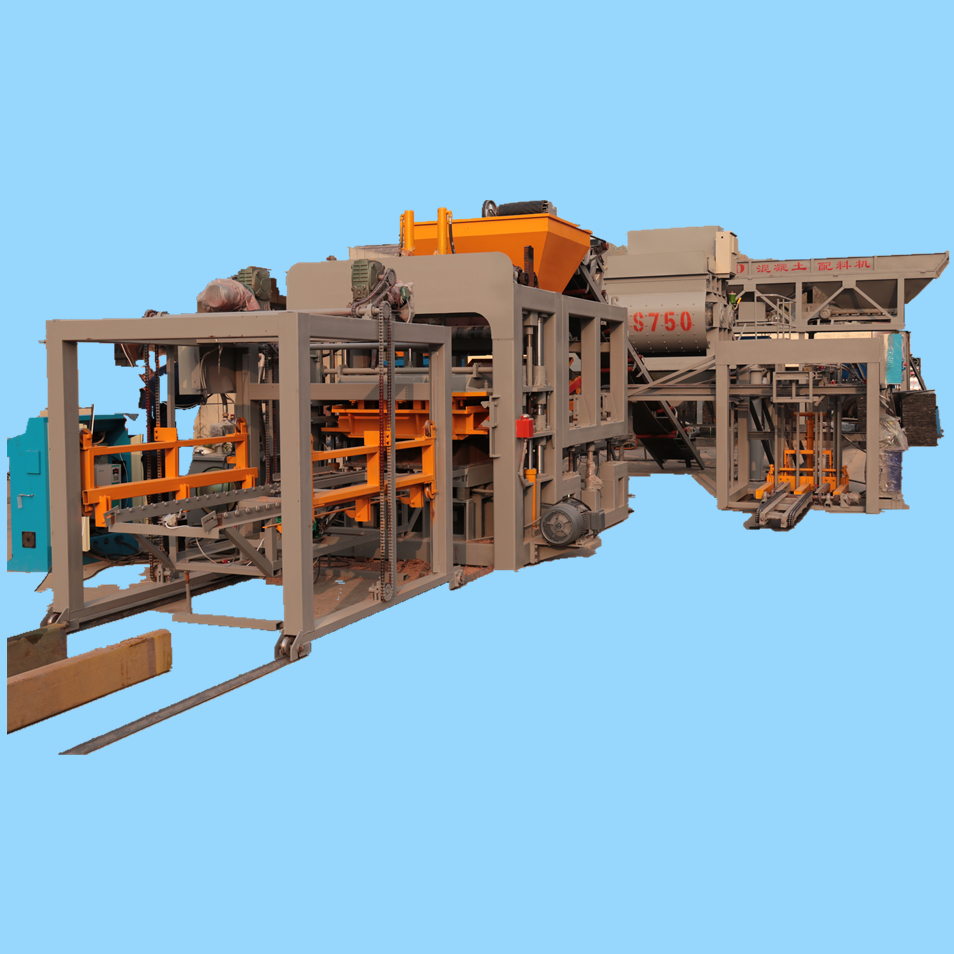

quadra block machine

Our quadra block machine are advanced technology block making machines that use hydraulic pressure to compress and shape raw materials such as Plywood sheets, cement and aggregate into high quality concrete blocks. We offer a variety of models with varying production capabilities and customizable features to meet our customers’ specific needs. Our machines are designed for efficiency and durability, with rugged construction and high-quality components ensuring long-term reliability and low maintenance costs.

In addition to producing traditional blocks, our machines are also capable of producing Catch basin blocks, hollow blocks and paving blocks in a variety of surface finishes such as smooth, textured or coloured. These blocks are widely used in construction projects for building walls, roads, walkways, and other structures.

Briefly about our block machines:

The QT12-15 is the biggest fully automatic block making machine with high productivity , it is suitable for big company who want to supply big projects;

the QT4-18 simple automatic block making machine is one the best selling brick machine model, because of its high cost to performance.

The QT4-24 semi automatic brick machine is also very popular because its low price and easy operating system;

The QT4-40 manual block making machine is very cheap for small investment, it can also make different blocks, bricks under different block moulds.

Other QT4-15 QT6-15 QT8-15 QT10-15 block machine models are mainly middle scale automatic brick machine line, they have different capacity and superiority;

As China Block Machine Factory, we would like to cooperate with the block machine Wholesaler from the world, communicate with the block machine factory supplier from the world to make progress together.

| Size (mm) | Qty/mould | mould cycle (s) | capacity per hour | daily capacity |

| hollow 400*200*200 | 6 | 20-25 s | 850-1100 | 6660-8800 |

| hollow 400*150*200 | 7 | 20-25 s | 1000-1300 | 7968-10400 |

| hollow 400*100*200 | 18 | 20-25 s | 1200-1400 | 7844-11200 |

The Advantages of Block Machine Technology

quadra block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.Does a quadra block machine require specialized training to operate?

3.About quadra block machine patent

4.About quadra block machine production management system

5.What is the production capacity of a quadra block machine?

6.About quadra block machine production capacity

7.Are there any design limitations when using a quadra block machine?

8.About quadra block machine raw materials

9.About quadra block machine inventory

10.Can a quadra block machine be used in disaster relief or emergency situations?

11.What are the key components of a quadra block machine?

12.Does a quadra block machine require a specific type of raw material?

13.Are there different levels of automation available for quadra block machines?

14.How does the weight of a block affect transportation and storage?

1.Does a quadra block machine have a warranty period?

Yes, most block machines come with a warranty period. The length of the warranty period varies depending on the manufacturer and model of the machine.

2.Does a quadra block machine require specialized training to operate?

We continuously upgrade our skills and knowledge to adapt to changing quadra block machine market needs.

Yes, a block machine typically requires specialized training to operate. Depending on the type of block machine, the operator may need to be trained in the use of the machine, safety protocols, and other related topics.

3.About quadra block machine patent

Block machine patents are patents that cover the design and operation of machines used to make blocks of various materials, such as concrete, clay, and other masonry materials. These machines are used in the construction industry to create walls, foundations, and other structures. Block machine patents typically cover the design of the machine, the operation of the machine, and the materials used in the production of blocks.

4.About quadra block machine production management system

The Block machine production management system is a software solution designed to help businesses manage the production of concrete blocks. It provides a comprehensive set of tools to help businesses track and manage the production process from start to finish. The system can be used to monitor production, track inventory, manage orders, and generate reports. It also provides features such as scheduling, cost tracking, and quality control. The system is designed to be user-friendly and can be customized to meet the specific needs of each business.

5.What is the production capacity of a quadra block machine?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

The production capacity of a block machine depends on the size and type of block being produced. Generally, a block machine can produce between 1,000 and 8,000 blocks per hour.

6.About quadra block machine production capacity

The production capacity of a block machine depends on the size of the blocks it is producing, the type of material being used, and the speed of the machine. Generally, a block machine can produce between 500 and 5,000 blocks per hour.

7.Are there any design limitations when using a quadra block machine?

Yes, there are several design limitations when using a block machine. These include the size of the blocks that can be produced, the type of material that can be used, the speed of production, and the amount of force that can be applied to the blocks. Additionally, the block machine may not be able to produce blocks with intricate designs or shapes.

8.About quadra block machine raw materials

Block machine raw materials are typically made from a combination of cement, sand, gravel, and water. The exact proportions of each material used will vary depending on the type of block being made. The raw materials are mixed together in a concrete mixer and then poured into a block machine, which forms the blocks. The blocks are then cured and hardened before being ready for use.

9.About quadra block machine inventory

Block machine inventory is a software system designed to help businesses manage their inventory of block machines. The system allows businesses to track the quantity of block machines in stock, the cost of each machine, and the location of each machine. The system also provides reports on the current inventory levels, the cost of each machine, and the location of each machine. Additionally, the system can be used to generate purchase orders and invoices for block machines.

10.Can a quadra block machine be used in disaster relief or emergency situations?

Yes, block machines can be used in disaster relief or emergency situations. Block machines can be used to quickly construct temporary shelters, walls, and other structures that can provide protection and shelter for those affected by a disaster. Block machines can also be used to create roads and pathways for emergency vehicles and personnel to access affected areas.

11.What are the key components of a quadra block machine?

We are a professional quadra block machine company dedicated to providing high quality products and services.

1. Concrete Mixer: This is used to mix the concrete and other materials used in the block production process.

2. Block Mould: This is the mould used to shape the blocks.

3. Hydraulic Press: This is used to press the blocks into shape.

4. Palletizing System: This is used to move the blocks from the press to the curing area.

5. Curing Area: This is where the blocks are cured and allowed to dry.

6. Packaging System: This is used to package the blocks for shipping.

12.Does a quadra block machine require a specific type of raw material?

Our quadra block machine products undergo strict quality control to ensure customer satisfaction.

Yes, a block machine typically requires a specific type of raw material, such as sand, gravel, cement, and water. Depending on the type of block machine, other materials may also be required.

13.Are there different levels of automation available for quadra block machines?

We operate our quadra block machine business with integrity and honesty.

Yes, there are different levels of automation available for block machines. Automation levels range from manual machines to fully automated machines. Manual machines require manual labor to operate, while fully automated machines are capable of producing blocks with minimal human intervention. Automation levels can also vary depending on the type of block machine being used.

14.How does the weight of a block affect transportation and storage?

The weight of a block affects transportation and storage in several ways. Heavier blocks require more energy to move and can be more difficult to transport. They also require more space for storage, as they take up more room than lighter blocks. Additionally, heavier blocks may require more specialized equipment for transportation and storage, such as forklifts or cranes.