- 28

- 2月

How does the vibration system in a block making machine help in the production process?

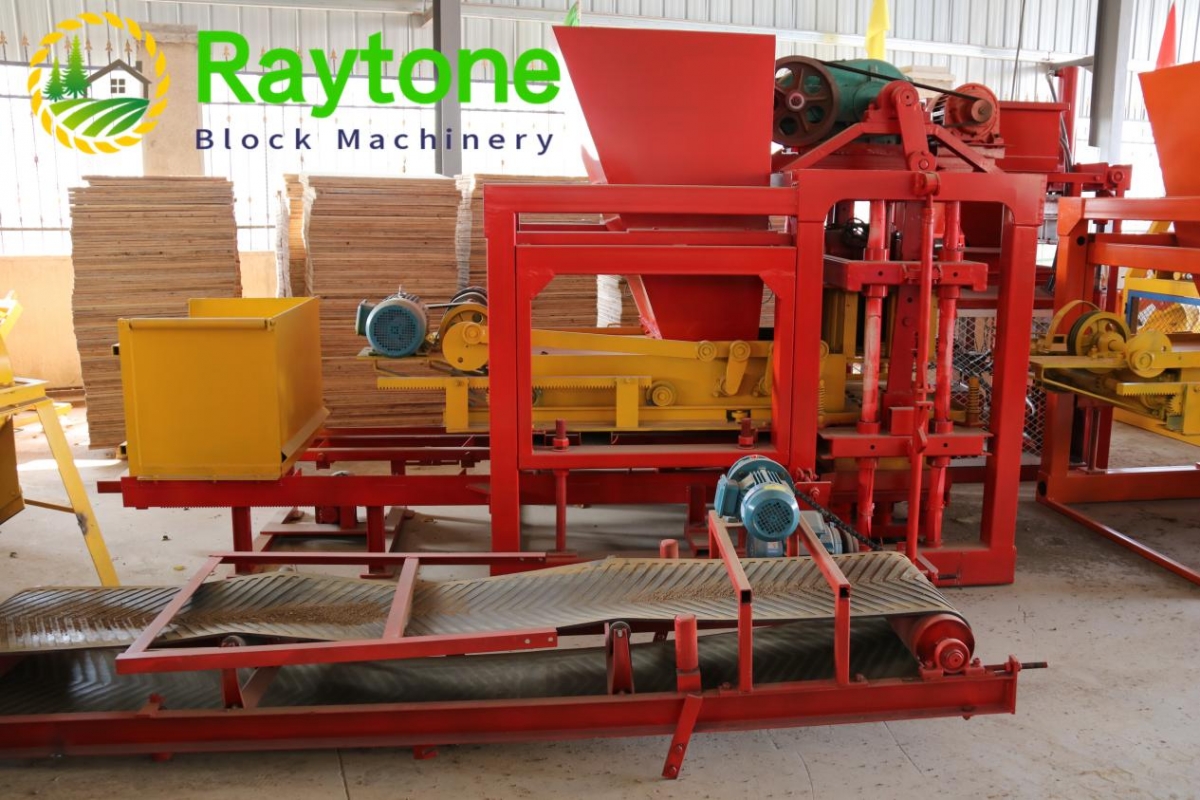

Our block making machines are designed to meet the diverse needs of our customers and offer solutions for various types of concrete products. We offer a wide range of machines, from simple manual machines to fully automated production lines, suitable for both small and large-scale production.

Our machines can produce a variety of concrete blocks, including hollow, solid, paving, and curb stones. They are highly efficient and can produce high-quality blocks within a short period of time. Equipped with advanced technology, our machines are also energy-efficient, reducing operating costs for our customers.

Innovation and customization are at the core of our product development. We offer a variety of customizable options, such as different block sizes and shapes, to meet the specific requirements of our clients. In addition, we also provide comprehensive training and technical support to ensure our customers can operate our machines easily and effectively.

The multi-purpose block machine is a highly versatile piece of equipment that can be used for a variety of purposes. From producing concrete blocks and bricks to manufacturing different types of pavers and tiles, this machine is an essential tool for any construction project. Its advanced technology and efficient design make it easy to operate, ensuring high-quality results every time.Designed with versatility in mind, this machine also allows for customization, making it suitable for different shapes, sizes, and designs. It can handle a wide range of materials, including cement, sand, and stone, providing endless possibilities for building and construction projects.

The revolutionary Block Machine is a groundbreaking solution that combines efficiency and automation to completely transform traditional block manufacturing processes. With its advanced technological capabilities, this machine greatly reduces the manual labor and time required for block production. Its automated features ensure a precise and consistent production process, resulting in high-quality blocks every time. Whether used for construction, landscaping, or other applications, the Block Machine delivers unparalleled efficiency and reliability. Say goodbye to labor-intensive and time-consuming methods – the future of block manufacturing has arrived.

Block making machine, also known as brick making machine, is a device that produces concrete blocks or bricks in various shapes and sizes. It plays an important role in the construction industry by providing a cost-effective and efficient solution for producing building materials. With the advancement of technology and the increasing demand for sustainable building materials, block making machines have evolved to become more versatile and eco-friendly. In this article, we will delve deeper into the functionalities and benefits of block making machines and explore how they have revolutionized the way we build structures.

2.Can a block making machine be used for multiple shifts or continuous production?

3.Can recycled materials be used in a block making machine?

4.How does the curing process work in a block making machine?

5.Is a block making machine easy to operate and maintain?

6.How long does it take to set up and install a block making machine?

7.What is the difference between a fully automatic and semi-automatic block making machine?

8.What safety measures should be taken while operating a block making machine?

9.What impact does the temperature have on the production process of a block making machine?

10.Can a block making machine produce both hollow and solid blocks?

11.What is the expected lifespan of a block making machine?

1.How does the block making machine handle the release of excess water during the curing process?

The block making machine does not handle the release of excess water during the curing process. This is typically done manually by the operator or through the use of a curing chamber or curing racks. The excess water is released by removing the blocks from the molds and allowing them to air dry or by placing them in a curing chamber where the temperature and humidity can be controlled to facilitate the curing process. Some block making machines may have built-in curing chambers or racks to aid in this process, but it is not a function of the machine itself.

2.Can a block making machine be used for multiple shifts or continuous production?

Yes, a block making machine can be used for multiple shifts or continuous production. These machines are designed to be durable and efficient, allowing them to run for extended periods of time without needing to be shut down for maintenance or repairs. However, it is important to follow the manufacturer’s guidelines for proper usage and maintenance to ensure the longevity and optimal performance of the machine.

3.Can recycled materials be used in a block making machine?

Yes, recycled materials can be used in a block making machine. Many block making machines have the capability to use a variety of materials, including recycled materials such as crushed concrete, fly ash, and recycled plastic. These materials can be mixed with cement and other additives to create strong and durable blocks. Using recycled materials in block making can also help reduce waste and promote sustainability. However, it is important to ensure that the recycled materials are clean and free from contaminants to ensure the quality of the blocks.

4.How does the curing process work in a block making machine?

The curing process in a block making machine involves the use of heat and moisture to harden and strengthen the concrete blocks. This process is essential for ensuring that the blocks have the necessary strength and durability to withstand the weight and pressure they will be subjected to in construction projects.

The curing process typically begins after the blocks have been molded and compacted in the block making machine. The blocks are then removed from the machine and placed on a curing rack or pallet, which is then transferred to a curing chamber.

In the curing chamber, the blocks are exposed to high humidity and temperature conditions, usually around 80-90% humidity and 60-80 degrees Celsius. This environment is maintained for a specific period, usually 24-48 hours, to allow the blocks to absorb moisture and heat, which helps in the chemical reaction that causes the concrete to harden.

The curing process can also be accelerated by using steam or hot water to increase the temperature and humidity levels in the curing chamber. This method is often used in large-scale block production facilities to speed up the curing process and increase production efficiency.

After the blocks have been cured, they are removed from the curing chamber and allowed to cool down before being stacked and stored for further curing. The total curing time for concrete blocks can vary depending on factors such as the type of concrete mix used, ambient temperature, and humidity levels.

In summary, the curing process in a block making machine is a crucial step in the production of high-quality concrete blocks. It ensures that the blocks have the necessary strength and durability to withstand the rigors of construction and provides a consistent and uniform product.

5.Is a block making machine easy to operate and maintain?

Yes, a block making machine is relatively easy to operate and maintain. Most modern block making machines come with user-friendly controls and instructions, making it easy for operators to learn and operate the machine. Additionally, regular maintenance and cleaning of the machine can help prolong its lifespan and ensure smooth operation. However, it is important to follow the manufacturer’s instructions and guidelines for proper maintenance and operation of the machine.

6.How long does it take to set up and install a block making machine?

The time it takes to set up and install a block making machine can vary depending on the specific machine and the experience of the person or team doing the installation. In general, it can take anywhere from a few hours to a few days to set up and install a block making machine. This includes assembling the machine, connecting any necessary electrical or hydraulic components, and testing the machine to ensure it is functioning properly. The process may also involve training on how to operate and maintain the machine.

7.What is the difference between a fully automatic and semi-automatic block making machine?

A fully automatic block making machine is a machine that can operate without any human intervention. It can automatically mix, mold, and stack the blocks without the need for manual labor. It is equipped with advanced technology and sensors that can control the entire process.

On the other hand, a semi-automatic block making machine requires some level of human intervention. It can perform some tasks automatically, such as mixing and molding, but it still requires manual labor for other tasks, such as stacking the blocks. It is less advanced and relies on manual control for certain functions.

8.What safety measures should be taken while operating a block making machine?

1. Wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and steel-toed boots.

2. Familiarize yourself with the machine’s operating manual and follow all safety instructions.

3. Ensure that the machine is properly grounded and all electrical connections are secure.

4. Keep the work area clean and free of clutter to prevent tripping hazards.

5. Do not wear loose clothing or jewelry that could get caught in the machine.

6. Never operate the machine if you are fatigued or under the influence of drugs or alcohol.

7. Keep hands and fingers away from moving parts and always use tools or push sticks to handle materials.

8. Do not attempt to make adjustments or repairs while the machine is running.

9. Use a lockout/tagout system to prevent accidental startup or movement of the machine.

10. Regularly inspect the machine for any signs of wear or damage and perform maintenance as recommended by the manufacturer.

11. Do not overload the machine with materials beyond its capacity.

12. Keep a fire extinguisher nearby in case of emergencies.

13. If the machine becomes jammed or stuck, turn it off and unplug it before attempting to clear the blockage.

14. Always have a first aid kit on hand and know how to use it in case of injuries.

15. Train all operators on proper machine operation and safety procedures.

9.What impact does the temperature have on the production process of a block making machine?

The temperature can have a significant impact on the production process of a block making machine. Here are some ways in which temperature can affect the production process:

1. Curing time: The temperature can affect the curing time of the blocks. Higher temperatures can speed up the curing process, while lower temperatures can slow it down. This can impact the overall production time and output of the machine.

2. Concrete mix: The temperature can also affect the concrete mix used in the block making machine. In colder temperatures, the concrete mix may freeze, making it difficult to work with. In hotter temperatures, the mix may dry out too quickly, affecting the quality of the blocks.

3. Machine performance: Extreme temperatures can also affect the performance of the block making machine. In very cold temperatures, the machine may have difficulty functioning properly, leading to lower production rates. In hot temperatures, the machine may overheat, causing it to malfunction.

4. Block quality: The temperature can also impact the quality of the blocks produced. Inconsistent temperatures can lead to variations in the curing process, resulting in uneven or weak blocks. This can affect the durability and strength of the blocks.

5. Maintenance: Temperature changes can also affect the maintenance of the block making machine. Extreme temperatures can cause wear and tear on the machine, leading to more frequent repairs and maintenance.

Overall, the temperature plays a crucial role in the production process of a block making machine. It is important to monitor and control the temperature to ensure consistent and high-quality production.

10.Can a block making machine produce both hollow and solid blocks?

Yes, some block making machines have the capability to produce both hollow and solid blocks. These machines have interchangeable molds that can be easily switched out to produce different types of blocks. However, some machines may only be able to produce one type of block, so it is important to check the specifications of the machine before purchasing.

11.What is the expected lifespan of a block making machine?

The expected lifespan of a block making machine can vary depending on factors such as the quality of the machine, frequency of use, and maintenance. However, on average, a well-maintained block making machine can last for 10-15 years.