- 21

- Dec

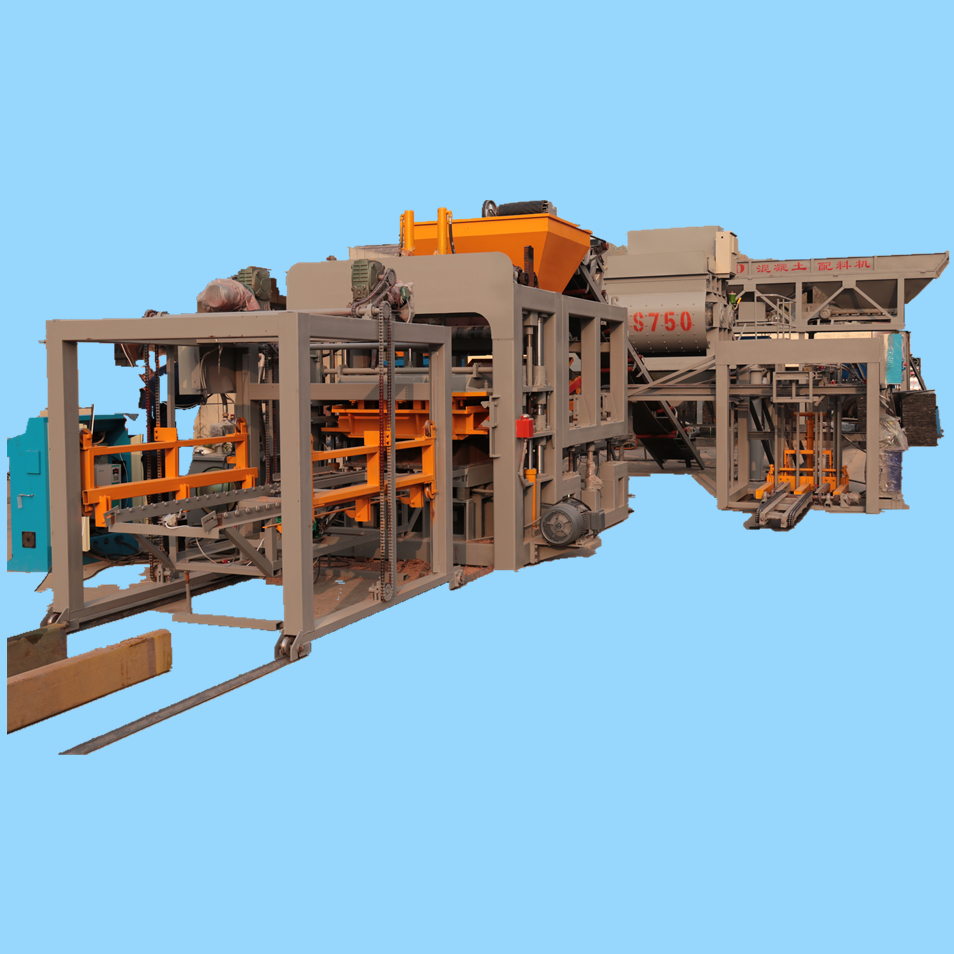

interlocking compressed earth block machine

Our block making machines are reliable and efficient machines used to produce different types of concrete blocks like Stone veneer blocks, solid blocks, interlocking blocks and paver blocks. They are suitable for both large and small-scale production, are versatile and cost-effective.

These machines are designed with advanced technology and components to ensure high quality and precise results. They are also easy to operate, maintain and have a long life, saving time and money in the long run.

Equipped with a sturdy steel frame and a powerful motor, our block making machines can easily produce up to 11131 of blocks per hour, saving you time and labor costs. It has a versatile mold configuration that can manufacture a variety of block types and sizes, from standard Stone veneer blocks to interlocking and Civil engineering projects.

One of the popular models is the QT4-15 interlocking compressed earth block machine, which has a production capacity of 800-2132 blocks per hour. It is equipped with an automatic control system and hydraulic components, making it easy to operate and maintain. The machine is also designed with a vibrating system, ensuring the even distribution of materials for consistent block quality. Its compact design allows for space-saving installation, making it suitable for both small and large scale production.

In terms of parameters, the QT4-15 interlocking compressed earth block machine can produce standard bricks, hollow blocks, and other custom shapes with adjustable mold height and vibration frequency. It also has a hopper size of 800x800mm and a conveyor belt for efficient material feeding. Additionally, it has a power output of 24.5kw, ensuring high production speed and energy efficiency.

| Feeding Capacity | 727L | Discharging Capacity | 503L |

| Depth | 0.5m | Motor Power | 11kw |

| Overall Size | 1500L*1500W*1350H (mm) | Diameter | 1500mm |

| Reducer | 315 reducer/ truck rear axle gear | Weight |

800kg |

How Block Machines Adapt to Any Project

interlocking compressed earth block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.About interlocking compressed earth block machine payment method

3.About interlocking compressed earth block machine raw material procurement system

4.What is the lifespan of a interlocking compressed earth block machine?

5.How does a interlocking compressed earth block machine handle different types of soils?

6.Can a interlocking compressed earth block machine produce eco-friendly blocks?

7.About interlocking compressed earth block machine production equipment

8.Can a interlocking compressed earth block machine be used in disaster relief or emergency situations?

9.Can a interlocking compressed earth block machine be connected to other construction equipment for seamless production?

10.Can a interlocking compressed earth block machine produce blocks with varying levels of compressive strength?

11.Are there any specific safety regulations for operating a interlocking compressed earth block machine?

12.About interlocking compressed earth block machine warranty

1.About interlocking compressed earth block machine inventory

Block machine inventory is a software system designed to help businesses manage their inventory of block machines. The system allows businesses to track the quantity of block machines in stock, the cost of each machine, and the location of each machine. The system also provides reports on the current inventory levels, the cost of each machine, and the location of each machine. Additionally, the system can be used to generate purchase orders and invoices for block machines.

2.About interlocking compressed earth block machine payment method

Block machine payment methods vary depending on the manufacturer and the type of machine. Some common payment methods include cash, credit cards, PayPal, wire transfers, and cryptocurrency. Some manufacturers may also offer financing options or leasing options.

3.About interlocking compressed earth block machine raw material procurement system

A block machine raw material procurement system is a software solution designed to streamline the process of procuring raw materials for the production of concrete blocks. The system automates the process of ordering, tracking, and managing the delivery of raw materials, allowing for greater efficiency and cost savings. The system also provides detailed reporting and analytics to help manufacturers better understand their supply chain and make informed decisions about their raw material procurement.

4.What is the lifespan of a interlocking compressed earth block machine?

Our products & services cover a wide range of areas and meet the needs of different fields.

The lifespan of a block machine can vary depending on the type of machine and how it is used. Generally, block machines can last anywhere from 10 to 20 years with proper maintenance.

5.How does a interlocking compressed earth block machine handle different types of soils?

A block machine is designed to handle a variety of soils, including clay, sand, gravel, and other aggregates. Depending on the type of soil, the machine may need to be adjusted to ensure the blocks are formed correctly. For example, if the soil is clay-based, the machine may need to be adjusted to increase the pressure and vibration to ensure the blocks are formed correctly. Additionally, the machine may need to be adjusted to ensure the blocks are formed with the correct amount of moisture.

6.Can a interlocking compressed earth block machine produce eco-friendly blocks?

As one of the interlocking compressed earth block machine market leaders, we are known for innovation and reliability.

Yes, a block machine can produce eco-friendly blocks. Many block machines are designed to produce blocks that are made from recycled materials, such as plastic, glass, and other materials. These blocks are often referred to as green blocks” and are becoming increasingly popular as a sustainable building material.”

7.About interlocking compressed earth block machine production equipment

Block machine production equipment is used to produce concrete blocks, bricks, and other masonry products. This equipment typically includes a mixer, a block machine, a conveyor, and a curing chamber. The mixer is used to mix the concrete, while the block machine is used to form the blocks. The conveyor is used to move the blocks to the curing chamber, where they are cured and hardened. The equipment is typically powered by electricity or diesel fuel.

8.Can a interlocking compressed earth block machine be used in disaster relief or emergency situations?

Yes, block machines can be used in disaster relief or emergency situations. Block machines can be used to quickly construct temporary shelters, walls, and other structures that can provide protection and shelter for those affected by a disaster. Block machines can also be used to create roads and pathways for emergency vehicles and personnel to access affected areas.

9.Can a interlocking compressed earth block machine be connected to other construction equipment for seamless production?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

Yes, a block machine can be connected to other construction equipment for seamless production. This is done by using a conveyor system to move the blocks from the block machine to other construction equipment, such as a mixer, for further processing. This allows for a more efficient and automated production process.

10.Can a interlocking compressed earth block machine produce blocks with varying levels of compressive strength?

Yes, a block machine can produce blocks with varying levels of compressive strength. This is done by adjusting the amount of pressure applied to the blocks during the manufacturing process. The amount of pressure applied can be adjusted to produce blocks with different levels of compressive strength.

11.Are there any specific safety regulations for operating a interlocking compressed earth block machine?

Being one of the top interlocking compressed earth block machine manufacturers in China, We attach great importance to this detail.

Yes, there are specific safety regulations for operating a block machine. These regulations vary depending on the type of block machine and the country in which it is being operated. Generally, safety regulations include wearing protective gear such as safety glasses, gloves, and a hard hat; ensuring that the machine is properly maintained and inspected; and following all safety instructions provided by the manufacturer. Additionally, operators should be trained in the proper use of the machine and be aware of any potential hazards associated with its operation.

12.About interlocking compressed earth block machine warranty

Block machine warranties vary depending on the manufacturer and model. Generally, warranties cover defects in materials and workmanship for a certain period of time, usually one year. Some warranties may also cover parts and labor for a certain period of time. It is important to read the warranty information carefully to understand what is covered and for how long.