- 28

- Mar

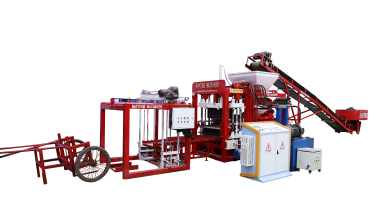

semi automatic block making machine oveerview: difinition, types, how to choose?

Definition

A semi-automatic block making machine is a machine that can produce different types and shapes of concrete blocks, bricks, and other construction materials. It is operated manually by a worker, unlike a fully automatic block making machine which requires less human intervention.

Types

1. Stationary semi-automatic block making machine

This type of machine is fixed in one location and can produce a large number of blocks in a short time. It is suitable for large-scale production.

2. Mobile semi-automatic block making machine

This type of machine is movable and can be transported from one location to another. It is suitable for construction sites and small-scale production.

3. Hydraulic semi-automatic block making machine

This type of machine uses hydraulic pressure to produce concrete blocks. It is the most commonly used type of semi-automatic block making machine.

4. Vibrating semi-automatic block making machine

This type of machine uses vibration to compact the concrete mixture, resulting in higher quality blocks.

5. Concrete hollow block making machine

This type of machine produces hollow blocks which are used for construction purposes.

6. Concrete paving block making machine

This type of machine produces interlocking or regular paving blocks used for roads, sidewalks, and other outdoor surfaces.

How to Choose

1. Production capacity

Consider the number of blocks you need to produce per day or per hour and choose a machine with a suitable production capacity.

2. Machine size and weight

Consider the available space for the machine and its transportation requirements.

3. Power source

Choose a machine with a power source that is compatible with your location and can provide enough energy for continuous operation.

4. Maintenance

Consider the frequency and complexity of maintenance for different machines and choose one that fits your requirements and budget.

5. Quality and durability

Choose a machine made with high-quality materials and has a track record of producing durable blocks.

6. User-friendliness

Choose a machine that is easy to operate and requires minimal training for the workers.

7. Cost

Compare the prices of different machines and choose one that fits your budget while still meeting your needs.

8. After-sales support

Choose a machine from a reputable manufacturer that provides good after-sales support, including training, spare parts, and repair services.

9. Customer reviews

Read reviews from other customers who have used the machine to know about their experience and satisfaction level.

a semi-automatic block making machine is a versatile and cost-effective option for producing different types of concrete blocks. By considering the production capacity, machine type, power source, maintenance, quality,and other factors, you can choose the right machine for your construction needs.

The semi-automatic block making machine is the perfect investment for your business, providing a high return on investment with its exceptional performance and durability. Its advanced features and advanced technology allow you to stay ahead of the competition and meet customer demands effortlessly.

Here are some frequently asked questions about semi automatic block making machine :

1. Can different types of molds be used with a semi-automatic block making machine?

Depending on the machine’s specifications, different types of molds can be used with a semi-automatic block making machine. This includes standard molds for bricks and blocks, as well as customized molds for specific block designs.

2. Can a semi-automatic block making machine be operated manually in case of power outages?

Yes, a semi-automatic block making machine can be operated manually in case of power outages. This requires the operator to manually perform all functions that would normally be controlled by the machine’s electrical system.

3. How does the vibration system affect the quality of blocks produced by a semi-automatic block making machine?

The vibration system in a semi-automatic block making machine helps in compacting the concrete mix, resulting in better block density and strength. This is important in producing high-quality blocks suitable for construction purposes.

4. Is it necessary to have a concrete batching plant when using a semi-automatic block making machine?

No, a concrete batching plant is not necessary when using a semi-automatic block making machine. However, having a batching plant on-site can provide a more efficient supply of concrete mix, resulting in smoother operation of the machine.

5. Are there any special requirements for the foundation of a semi-automatic block making machine?

The foundation requirements for a semi-automatic block making machine may vary depending on its weight and stability. It is recommended to follow the manufacturer’s guidelines for proper foundation construction to ensure the machine’s stability and safety.

6. Are spare parts readily available for a semi-automatic block making machine?

Yes, manufacturers usually provide spare parts for their semi-automatic block making machines. It is recommended to inquire about the availability of spare parts before purchasing a machine to ensure easy access in case of maintenance and repairs.

7. How does a semi-automatic block making machine contribute to efficient manpower utilization?

A semi-automatic block making machine contributes to efficient manpower utilization by reducing the need for manual labor in block production. This allows for manpower to be allocated to other tasks, resulting in improved productivity.

8. Can a semi-automatic block making machine be used for production in remote areas?

Yes, a semi-automatic block making machine can be used for production in remote areas. It is recommended to choose a machine with an easy-to-transport design and the ability to use locally sourced raw materials for more efficient and cost-effective production.