- 10

- Dec

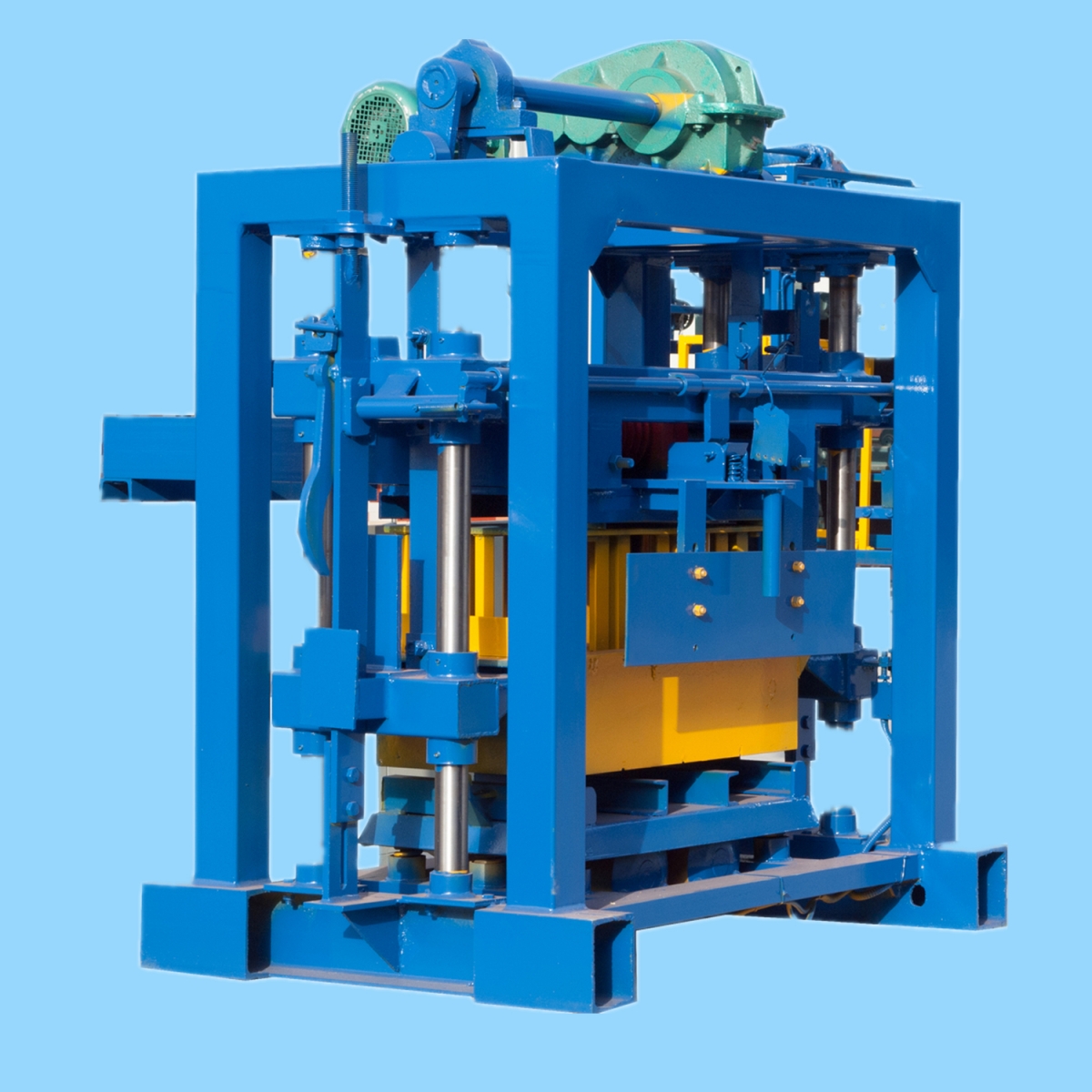

QT4-40 Manual Block Machine

1.QT4-40 Manual Block Machine Generally Description

QT4-40 Manual block machine is an easy operated brick machine, any workers can operate this block machine after short time training; the block machine price is cheap, suitable for small investment.

QT4-40 Hollow block machine productivity is 2880 pieces of 8 inch hollow blocks per day.

QT4-40 Solid block machine price is from 3700 USD to 10000 USD, depends on the extra mould quantity.

2. QT4-40 block machine Basic Requirement to start

The following information is take 8 inch hollow block for example for the client reference, the production data may be a little different as per different block or brick producing.

| land area | 200 Square Meters | Water Consumption | 1.6 T/day |

| Workshop area | 20 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 4workers | Power Consumption | 17.9KW*8 Hours=143.2 KWH; |

| Cement Consumption | 4.7 Tons per day | Sand consumption | 19 tons per day |

| Crushed stones consumption | 23.7 tons per day |

3.Each QT4-40 Block Machine single machine detailed introduction

(1) JQ350 Concrete Mixer for QT4-40 Brick Machine

Diameter: 1.2 M

Power: 7.5KW

Input : 500L

Output: 350L

Dimension: 1.2*1.2*1.4 M

Weight: 350KG

(2)QT4-40 host brick machine

Total Power: 10.4KW

Power: bottom vibrator: 3KW*2

Top Vibrator: 2.2KW

JZQ350 reducer

Mould Lift motor: 2.2KW

Block Machine dimension: 1780*1430*1900mm

Block Machine weight: 1500KG

Cycle time: 35-40 Seconds

(3) Block Moulds for QT4-40 manual block machine

The block moulds are made from 16# Manganese steel to give the mould long life, the paver brick moulds also need linear cutting procedure, it is more complicated.

(4)Manual Trolley for QT4-40 Brick Machine

RAYTONE manual trolley is using good quality wheel instead of poor quality wheel only with several months life, one machine line is equipped with 2 sets of manual trolley.

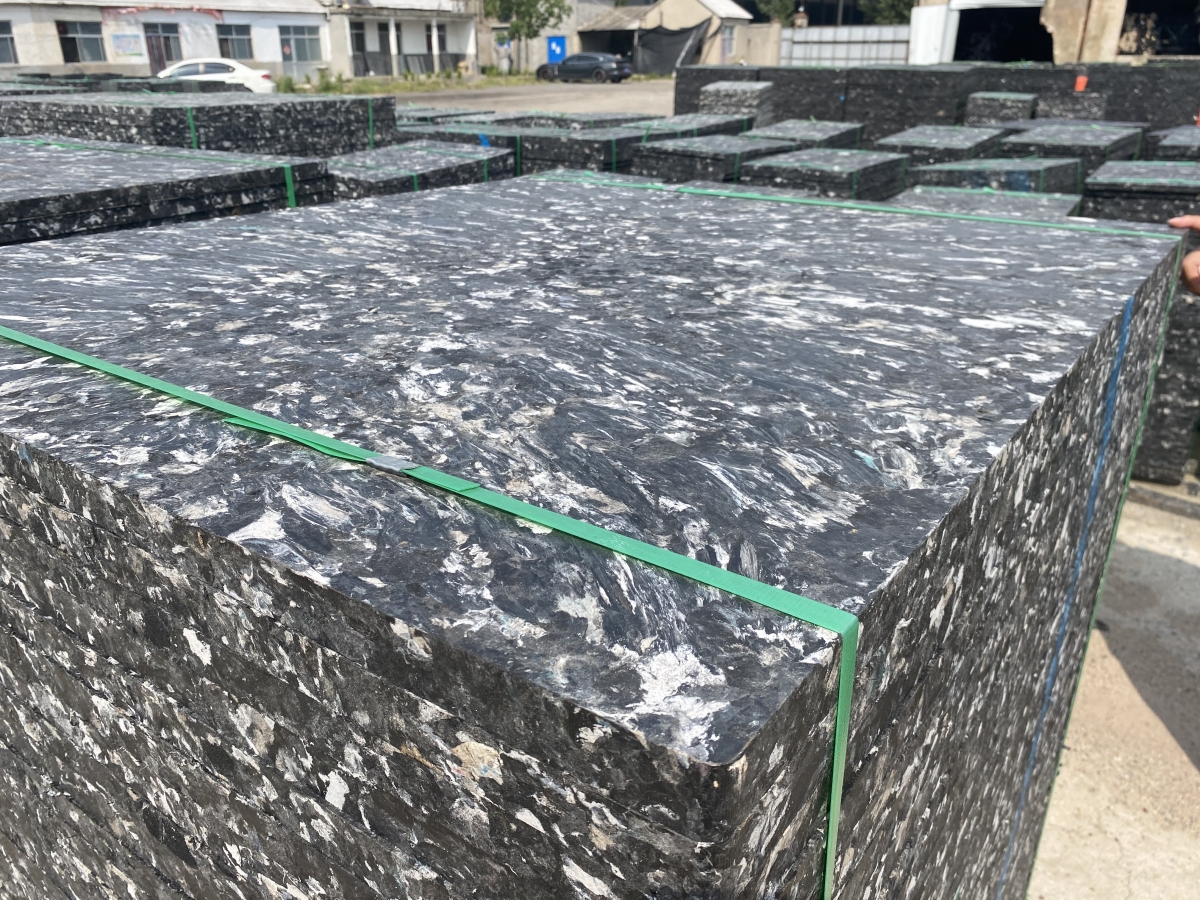

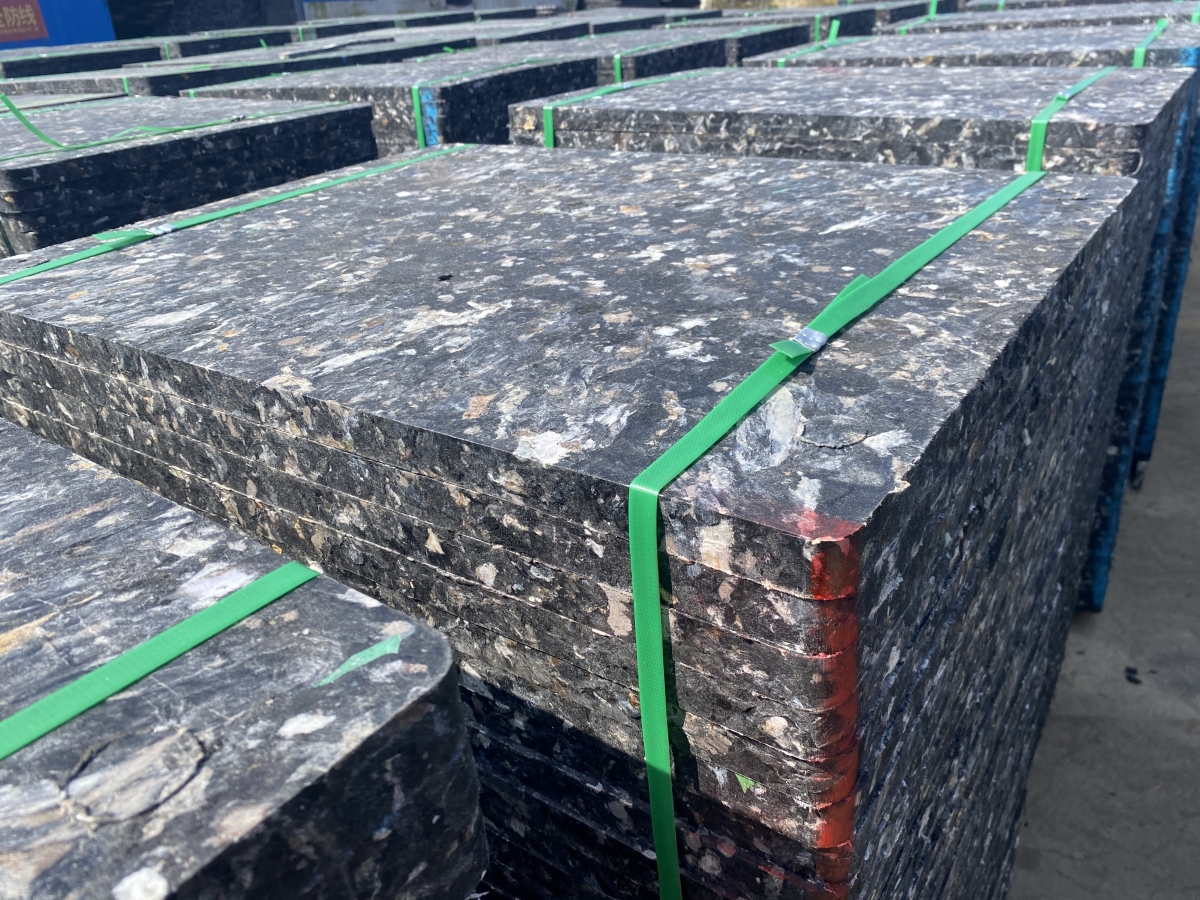

(5) GMT brick pallet for QT4-40 block making machine

GMT brick pallet is made from the left overs from the car inner roof, seats cushions, the materials are containing a lot adhesive, after they are crushed into small pieces, through heating, high pressure pressing, colding, grinding, then the final Brick Pallet comes out, the brick pallet quality is very good, it is the best cost to performance block pallet now among PVC brick pallet, Wooden pallet, Bamboo brick pallet, etc

4. QT4-40 Manual Block Machine Daily Productivity

| QT4-40 Block Machine Theoretical production capacity | ||||||

| Size(LxWxH) (mm) | Photo | Forming Period (S) | Pcs/ Mould | Pcs/Hour | Pcs/ 8 hours | |

| (1) | hollow block 400*250*200 |

|

40-50 | 3 | 216-270 | 1728-2160 |

| (2) | hollow block 400*200*200 |

|

35-45 | 4 | 288-360 | 2304-2880 |

| (3) | hollow block 400*150*200 |

|

35-45 | 5 | 360-450 | 2880-3600 |

| (4) | hollow block 400*100*200 |

|

35-45 | 7 | 504-630 | 4032-5040 |

| (5) | Solid Brick 240*50*115 |

|

35-45 | 18 | 1296-1620 | 10368-12960 |

| (6) | Porous Brick 240*115*90 |

|

35-45 | 9 | 648-810 | 5184-6408 |

| (7) | Curbstone 500*200*300 |

|

35-45 | 1 | 72-90 | 576-720 |

| (8) | “I” shape paver brick without color 200*163*60 |

|

35-45 | 6 | 432-540 | 3456-4320 |

| (9) | “S” Shape Paver Brick without color 225*112.5*60 |

|

35-45 | 9 | 648-810 | 5184-6408 |

| (10) | Holland Brick without color 200*100*60 |

|

35-45 | 9 | 648-810 | 5184-6408 |

| (11) | Square Paver wihtout color 250*250*60 |

|

35-45 | 3 | 216-270 | 1728-2160 |

5. video Link for QT4-40 Brick Making Machine

6. packing list of QT4-40 Block Making Machine

| 1 | JQ350 Pan Mixer | 1 set | 4 | Manual trolleys | 2 sets |

| 2 | QT4-40 Host Brick Machine | 1 set | 5 | GMT brick pallet | 600 pieces |

| 3 | Electrical PLC control Panel | 1 set | 6 | Spare parts | 1 set |

7. Block Photos made from QT4-40 Block Machine

The manual block machine can make most types of blocks via changing different block moulds;

8.Why choose RAYTONE block machine manufacture

(1) Easy operation, the machine operation is simple, workers can learn very fast;

(2) Movable, because machine is small, it is easier to change its working site when needed.

(3) Good quality, the machines are all tested well before delivery.

9.FAQ

(1) How many workers are needed for this block machine

1 worker to load raw materials into the mixer by wheel barrow or by small wheel loader machine;

1 worker operate the host brick machine

2 workers carry the produced fresh blocks to curing area.

Total 4 workers are needed.

(2) What kind of blocks can this QT4-40 brick machine make?

The QT4-40 manual block machine can produce many different types, sizes blocks or bricks like hollow block, solid brick, interlocking blocks, curbstones etc, by changing different block mould. But the QT4-40 brick machine cannot make the paver bricks with color, because it has no color feeding machine.

(3) What is the advantage of this QT4-40 manual block machine

The QT4-40 brick machine is simple, so its installation is easy, easy operation, and cost is low, at the same time, it needs small production area of 20 Square Meters is enough for starting making bricks, just need 4 workers, so it is very suitable for home use for small projects and new starters.

(4) How to maintain the QT4-40 manual block making machine

It is an easy maintaining, do the cleaning of the concrete mixer and block moulds after finishing work every day; Fasten the bots and nuts if any loosen; lubricate oil to the moving and friction parts.

(5) What is the delivery time for this QT4-40 block making machine

Normally 20 days from the day we receive the deposit.

10. RAYTONE Company service

RAYTONE block machine manufacture provide good after sales service to guide the client to operate the block machine;

RAYTONE block machine manufacture supply the all the trouble shooting service to the client during their machine use;

RAYTONE block machine factory supplies all the spare parts, moulds the whole life of the block machine.

If you are interesting in RAYTONE block Machines, please contact for more details without hesitate.