- 20

- Dec

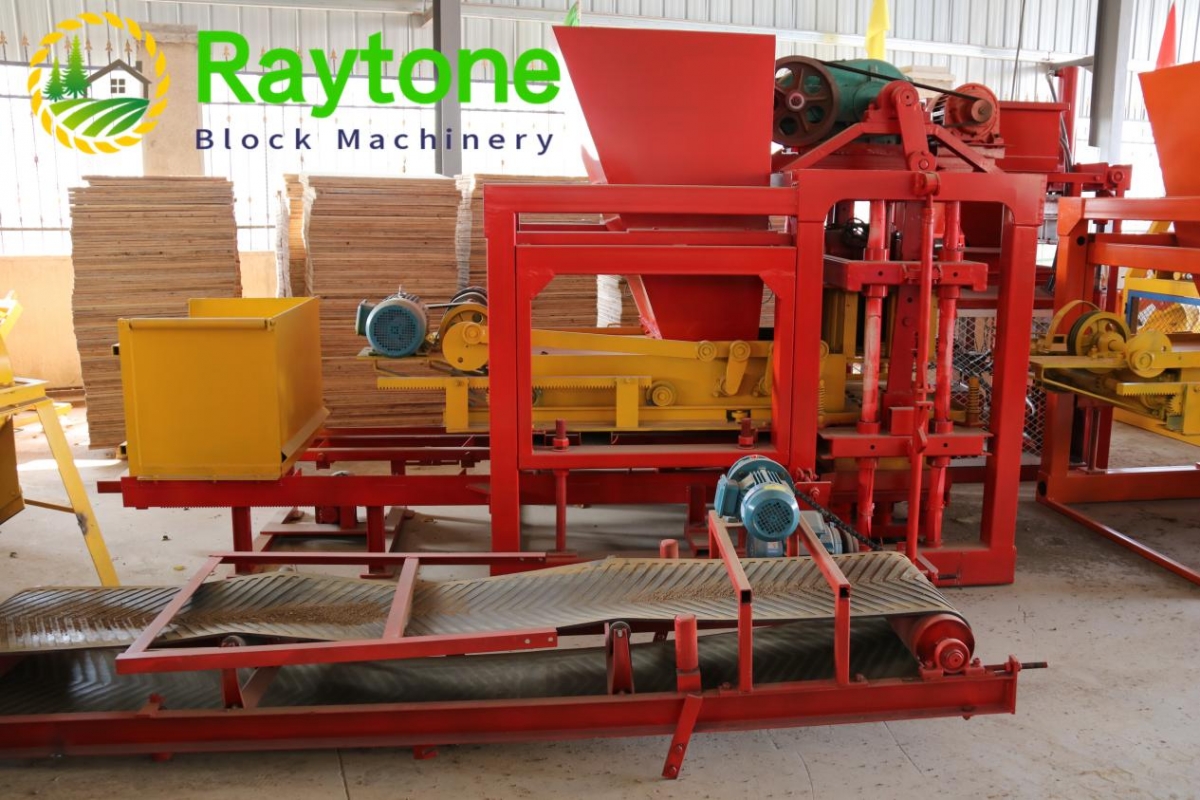

customized block machine

Our customized block machine are designed with efficiency, durability and versatility in mind. They can produce blocks in a variety of shapes and sizes, including standard Exposed aggregate concrete blocks, interlocking paving stones and hollow blocks. They are also highly customizable to meet specific production requirements and blocks can be produced quickly, saving time and labor.

These block making machines are ideal for both small and large scale production and are suitable for a variety of applications including Manhole and sewer repair, road paving, landscaping and more. We also provide excellent after-sales support, with spare parts readily available and technical support for any maintenance or technical issues.

Block Machine Technical Specifications:

1. Power: 393V-405V, 46-57Hz, 3 phase

2. Production Capacity: 5724-7093 blocks per hour

3. Block Types: Hollow blocks, solid blocks, paver blocks, and more

4. Block Size: Customizable according to customer needs

5. Weight: Approx. 2527 kg

6. Dimensions: 3114x1502x2924 mm

Our block making machines are the top solution for all your Gabion blocks production needs. With its high productivity, durability and versatility, it is the perfect choice for large-scale industrial manufacturing. Contact us today to learn more and start your block production process!

One of the most popular models is the fully automatic customized block machine, which is equipped with advanced technology and can produce blocks of various shapes and sizes with high precision. It has a production capacity of up to 10,000 blocks per hour and can be operated by just one person.

Another model is the semi-automatic customized block machine, which also has a high production capacity of up to 8,000 blocks per hour. It requires some manual labor, but still offers a faster and hassle-free production process.

The manual customized block machine is a budget-friendly option for producing blocks on a smaller scale. It has a production capacity of up to 4,000 blocks per hour and requires more manual labor compared to the other models.

All the models of the customized block machine are equipped with high-quality material and components, ensuring durability and long-lasting performance. They also have adjustable parameters for block size, thickness, and density, allowing for customization according to specific requirements.

| Feeding Capacity | 570L | Discharging Capacity | 456L |

| Depth | 0.5m | Motor Power | 11kw |

| Overall Size | 1500L*1500W*1350H (mm) | Diameter | 1500mm |

| Reducer | 410 reducer/ truck rear axle gear | Weight |

800kg |

Block Machines Redefining Building Standards

customized block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.Are there any design limitations when using a customized block machine?

3.What is the power source for a customized block machine?

4.About customized block machine technology

5.Can a customized block machine be used for large scale production?

6.What are the maintenance costs associated with running a customized block machine?

7.How much space is needed to operate a customized block machine?

8.Are there any noise or vibration concerns with a customized block machine?

9.Are there any safety features built into the design of a customized block machine?

10.Can a customized block machine be connected to other construction equipment for seamless production?

11.About the development history of customized block machine factory

12.What is the lifespan of a customized block machine?

13.Are there safety precautions that need to be taken while operating a customized block machine?

1.About customized block machine customization services

Block machine customization services are designed to help businesses create custom-made block machines that are tailored to their specific needs. These services can include the design and engineering of the machine, the fabrication of the components, and the installation and maintenance of the machine. The customization services can also include the development of software and hardware to control the machine, as well as the integration of the machine into existing production lines. The customization services can also include the development of custom-made parts and components for the machine, as well as the development of custom-made tools and fixtures for the machine.

2.Are there any design limitations when using a customized block machine?

Yes, there are several design limitations when using a block machine. These include the size of the blocks that can be produced, the type of material that can be used, the speed of production, and the amount of force that can be applied to the blocks. Additionally, the block machine may not be able to produce blocks with intricate designs or shapes.

3.What is the power source for a customized block machine?

Our products & services cover a wide range of areas and meet the needs of different fields.

The power source for a block machine is typically an electric motor. Some block machines may also be powered by a diesel engine.

4.About customized block machine technology

Block machine technology is a type of construction technology that is used to produce concrete blocks. It is a process that involves mixing cement, sand, and water to form a concrete mixture, which is then poured into a mold and compressed to form a block. The blocks are then cured and hardened before being used in construction projects. Block machine technology has been used for centuries to create strong and durable structures. It is a cost-effective and efficient way to build structures that are both aesthetically pleasing and structurally sound.

5.Can a customized block machine be used for large scale production?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, block machines can be used for large scale production. Block machines are designed to produce large quantities of concrete blocks in a short amount of time. They are typically used in the construction industry to produce blocks for walls, foundations, and other structures.

6.What are the maintenance costs associated with running a customized block machine?

The maintenance costs associated with running a Block machine will vary depending on the type of machine and its age. Generally, maintenance costs can include regular oil changes, filter replacements, lubrication, and other routine maintenance. Additionally, more complex repairs such as replacing worn parts or repairing electrical components may be necessary. Depending on the machine, these repairs can be costly.

7.How much space is needed to operate a customized block machine?

We have established a good reputation and reliable partnerships within the customized block machine industry.

The amount of space needed to operate a block machine will depend on the size and type of machine. Generally, a block machine will require a minimum of 10 feet by 10 feet of space.

8.Are there any noise or vibration concerns with a customized block machine?

Yes, noise and vibration are common concerns with block machines. The noise and vibration levels can vary depending on the type of machine and the materials being used. It is important to ensure that the machine is properly maintained and that the operator is properly trained to reduce the risk of excessive noise and vibration.

9.Are there any safety features built into the design of a customized block machine?

Yes, there are several safety features built into the design of a block machine. These include emergency stop buttons, safety guards, and interlocks to prevent accidental operation. Additionally, many block machines are designed with a low center of gravity to reduce the risk of tipping over.

10.Can a customized block machine be connected to other construction equipment for seamless production?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

Yes, a block machine can be connected to other construction equipment for seamless production. This is done by using a conveyor system to move the blocks from the block machine to other construction equipment, such as a mixer, for further processing. This allows for a more efficient and automated production process.

11.About the development history of customized block machine factory

The development history of block machine factory can be traced back to the early 20th century. The first block machine was invented in the United States in 1905 by a man named Charles Pankow. This machine was used to make concrete blocks for construction projects. In the 1920s, the first automatic block machine was developed in Germany. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines.

In the 1950s, the first hydraulic block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines. In the 1960s, the first computer-controlled block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines.

In the 1970s, the first fully automated block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines. In the 1980s, the first robotic block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines.

Today, block machine factories are used to produce a wide variety of blocks for construction projects. They are used to produce blocks for residential, commercial, and industrial projects. Block machine factories are also used to produce blocks for landscaping projects.

12.What is the lifespan of a customized block machine?

Our products & services cover a wide range of areas and meet the needs of different fields.

The lifespan of a block machine can vary depending on the type of machine and how it is used. Generally, block machines can last anywhere from 10 to 20 years with proper maintenance.

13.Are there safety precautions that need to be taken while operating a customized block machine?

As one of the top customized block machine manufacturers in China, we take this very seriously.

Yes, there are several safety precautions that should be taken when operating a block machine. These include:

1. Wear appropriate safety gear, such as safety glasses, gloves, and a hard hat.

2. Make sure the machine is properly grounded and that all electrical connections are secure.

3. Ensure that the machine is properly lubricated and that all moving parts are in good working order.

4. Keep the work area clean and free of debris.

5. Make sure that all guards and safety devices are in place and functioning properly.

6. Make sure that all operators are properly trained and familiar with the machine’s operation.

7. Make sure that all operators are aware of the potential hazards associated with the machine and take the necessary precautions to avoid them.

8. Make sure that all operators are aware of the emergency stop button and know how to use it in case of an emergency.