- 01

- Dec

Latest Hollow Block Machine Suppliers – No Broker Needed

Out of the many construction machines available, the most beneficial one is a hollow block making machine.

In the modern day and age, when almost all work is done via machinery, Construction is one of the few large industries which still utilize hand labor for the most part. Yet, there are still a few ways through which the tiring work of laborers is made more manageable. The most prominent is using machinery for exceptionally time-taking tasks like mixing cement, removing excess rubble, or rapidly transporting raw materials.

As is common knowledge, concrete blocks are superior to brick blocks since they are bigger and have fewer joints. It contributes to precision maintenance, homogeneity, and building strength improvement. In addition to improving thermal insulation and water protection, it speeds up construction and lowers overall costs.

Hollow block-making machines are, as the name suggests, used to manufacture concrete blocks in bulk quantities that take too much time if made otherwise. The machines support automated brick production, creating blocks of various shapes, sizes, and dimensions using vibration and hydraulic force to press the concrete mortar into the hollow molds.

How Do Hollow Block Machines Work?

First, the mortar must be prepared with the correct ratio of ingredients. In most cases, we add 1 unit of cement into every 4 units of additives and dry sand before mixing it with the right amount of water to achieve the perfect consistency. This is one of the most significant actions as it determines the quality of the batch of bricks.

The mortar is then thoroughly blended via a mixer and transferred into the hopper of a block-making machine by a conveyor belt.

The machine handles the remaining work. The mortar is first put into a device known as a cart, which then begins to fill the mold by revolving back and forth. The mortar starts to vibrate after the mold is full, filling the microscopic gap between the sands. As the machine vibrates, the mortar’s surface contracts. Before the press begins, the mortar cart fills the mold one last time.

The bottom and top molds press on the pallets’ surface. Both molds rise once the pressing starts, and the finished block is automatically transferred to the hollow block machine’s output.

A forklift or a finger car system handles the automated block collection system in the hollow block machine. It is far quicker and uses less room for the drying portion. In the manual process, each block is physically delivered and stowed before being moved to be dried in the curing room or drying area and rested there for some time before delivery.

The block’s size changes with the machine’s size, and as the machine gets bigger, the block must also get bigger and thicker. Because of the maintenance, the quality of the block is crucial. Bricks of better quality may be used much longer, saving replacement costs.

There are two general types of hollow block-making machines:

Mobile Hollow Block-Making Machine

A mobile block-making machine is much easier to use. It has more straightforward and much cheaper options, but most important jobs, like transferring the mortar, preparing the mixture, and operating its functions, must be done manually.

It has a much smaller production capacity and is best suited for small-scale, low-budget projects. A steel plate is moved back and forth to create the concrete blocks. The mortar is then crushed and allowed to dry on the floor, producing a flawless final result.

Mobile hollow Block Machine models as below:

| QTM12-15 Mobile hollow Block Making Machine | |

| Descriptions:

QTM12-15 is a big size mobile concrete block machine, it can lay 12 pieces of 8 inch hollow blocks per drop, it has a large productivity. High density blocks, fast shaping speed. This machine doesn’t need brick pallets to support, but need large concrete ground area for laying concrete blocks. QTM12-15 is well designed for the machine structure, its high quality steel and precision welding technology makes the machine more stable and long life; also its hydraulic vibration box has strong vibration force. |

|

| Photo: | Specifications: |

|

1.Mould Changeable, Hollow, Solid |

| 2. Capacity: 8 inch Block daily Capacity: 21600pcs; | |

| 3. full Machine Line Price Range:18000-32000USD | |

| 4. Factory Area: 100-2500 m2; Workers Number:3-4; | |

| QTM10-15 Mobile hollow Block Making Machine | |

| Descriptions:

QTM10-15 hollow block machine is making 10 pieces of 8 inch hollow block per drop, it can produce various hollow blocks, solid bricks, it has multi functions of electric walking, hydraulic steering, and auto air cooling system; The vibration box is one whole casting unit, not welding, it is stronger and longer life than welding vibration box; |

|

| Photo: | Specifications: |

|

1.Mould Changeable, Hollow, Solid |

| 2. Capacity: 8 inch Block daily Capacity: 18000 pieces; | |

| 3. full Machine Line Price Range: | |

| 4. Factory Area: 1000-2500 m2; Workers Number:3-4; | |

| QTM6-25 Mobile hollow Block Making Machine | |

| Descriptions:

QTM6-25 is a simple brick production line without pallets, it matched with PLD800 concrete batching machine, JS500 concrete mixer, makes concrete block on ground with high efficiency. The block mould are using precise linear cutting method and carburation heat treatment to prolong its service life; |

|

| Photo: | Specifications: |

|

1.Mould Changeable, Hollow, Solid |

| 2. Capacity: 8 inch Block daily Capacity: 6800 pieces; | |

| 3. full Machine Line Price Range: 16000-31000USD | |

| 4. Factory Area: 1000-1500 m2; Workers Number:3-4; | |

| QTM4-40 Mobile hollow Block Making Machine | |

| Descriptions:

QTM4-40 is a Small mobile hollow block machine with hydraulic pressing, small investment suitable for new starters; its major vibration is mould vibration, together with hydraulic press, it makes good performance on the concrete blocks of its density and outlook ; |

|

| Photo: | Specifications: |

|

1.Mould Changeable, Hollow, Solid |

| 2. Capacity: 8 inch Block daily Capacity: 2880 pieces; | |

| 3. full Machine Line Price Range: 3200-3500USD | |

| 4. Factory Area: 600-1000 m2; Workers Number:3-4; | |

| QTM4-45 Mobile hollow Block Making Machine | |

| Descriptions:

QTM4-45 mobile hollow block machine is using vibrator motors on both press head and mould frame, it has a simple machine structure makes it easy to operate , no need installation and maintaining. |

|

| Photo: | Specifications: |

|

1.Mould Changeable, Hollow, Solid |

| 2. Capacity: 8 inch Block daily Capacity: 1920 pieces; | |

| 3. full Machine Line Price Range: 3000-3200USD | |

| 4. Factory Area: 600-1000 m2; Workers Number:2-3; | |

| QMY4-45 Diesel Mobile hollow Block Making Machine | |

| Descriptions:

QMY4-45 is diesel engine concrete block machine designed for the projects that are in the area short of electricity or in rural area; It is can be matched with movable diesel 350 concrete mixer, |

|

| Photo: | Specifications: |

|

1.Mould Changeable, Hollow, Solid |

| 2. Capacity: 8 inch Block daily Capacity: 1920 pieces; | |

| 3. full Machine Line Price Range: 2800-3000USD | |

| 4. Factory Area: 600-1000 m2; Workers Number:3-4; | |

| QTM2-45 Diesel Mobile hollow Block Making Machine | |

| Descriptions:

QTM2-45 is the smallest concrete block machine, it can make 2 hollow block per mould, but this mobile block machine is also able to make different size blocks, solid bricks. It is suitable fore individuals to build their own home with low cost. |

|

| Photo: | Specifications: |

|

1.Mould Changeable, Hollow, Solid |

| 2. Capacity: 8 inch Block daily Capacity: 920 pieces; | |

| 3. full Machine Line Price Range: 800-1000USD | |

| 4. Factory Area: 600-1000 m2; Workers Number:3-4; | |

Stationary Hollow Block-Making Machines

A stationary hollow block machine is a bigger, more powerful machine that also comes in various models, levels of automation, and extra components. It is the industrial equivalent of mobile hollow block-making machines.

During an eight-hour shift, the smallest Stationary hollow block machine makes 4.000 hollow concrete blocks or 12.000 paving blocks, while the largest Stationary machine generates 24.000 hollow concrete blocks or 56.000 paving blocks.

Stationary hollow block making machines models as below:

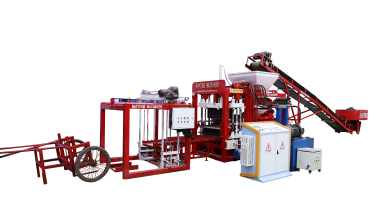

| QT10-15 Stationary Hollow Block Making Machine | |

| Descriptions:

QT10-15 hollow block machine moulds are easily inter-changeable, allowing a wide production range of different block and bricks; The block machine can be optionally equipped with color feeder to make face mix bricks; It has a high speed of the translation of up and downs machine movements; The brick and block making machine is a reliable, durable and very easy to operate and maintain machine. |

|

| Photo: | Specifications: |

|

1.Mould Changeable, Hollow, Solid, Color Paver, Curbstone,etc |

| 2. Capacity per 8 hours:

a. 8 inch Block Capacity: 19200 pieces; b. 240*115*50mm solid bricks: 99840 pieces; |

|

| 3.Brick pallet size: 1100*900*35mm | |

| 4. Machine Line Price Range:49400-82000USD | |

| 5.Factory Area: 2500-6500 m2; Workers Number:4-5; | |

| QT8-15 Stationary Hollow Block Making Machine | |

| Descriptions:

QT8-15 hollow block machine is also a big size machine, its PLC control panel has Siemens brand as optional, the internal electric parts are world famous brand like Germany Schneider breaker, Japan Omron Senors, China CHNT switches, China Vicruns Frequency converter, Taiwan Clyca brand electromagnetic valves etc. Also for electric motors with Siemens brand optional, The machine is coming standard with one maxi, hollow or stock block mould. Additional block moulds are at extra cost. QT8-15 is a high output block machine, with a great value for money. |

|

| Photo: | Specifications: |

|

1.Mould Changeable, Hollow, Solid, Color Paver, Curbstone,etc |

| 2. Capacity per 8 hours:

a. 8 inch Block Capacity: 15360 pieces; b. 240*115*50mm solid bricks: 80640 pieces; |

|

| 3.Brick pallet size: 960*850*30mm | |

| 4. Machine Line Price Range:45400-70800USD | |

| 5.Factory Area: 2500-6500 m2; Workers Number:4-5; | |

| QT6-15 Stationary Hollow block Making Machine | |

| Descriptions:

QT6-15 is a middle scale automatic concrete block machine model, it is equipped with 2 or 3 bin batching machine, 500 liters twin shaft concrete mixer, automatic wet block stacking machine; the automatic brick pallet feeder and brick face color feeder can be offered as optional. QT6-15 is also using User Friendly Touch Screen control on the PLC panel. QT6-15 block machine is well-constructed, have a stable vibration for high output brick that are ASBS compliant. |

|

| Photo: | Specifications: |

|

1.Mould Changeable, Hollow, Solid, Color Paver, Curbstone,etc |

| 2. Capacity per 8 hours:

a. 8 inch Block Capacity: 11520 pieces; b. 240*115*50mm solid bricks: 63360 pieces; |

|

| 3.Brick pallet size: 960*700*30mm | |

| 4. full Machine Line Price Range:32600-53400USD | |

| 5.Factory Area: 1200-2500 m2; Workers Number:4-5; | |

| QT5-15 Stationary Hollow Block Making Machine | |

| Descriptions:

QT5-15 is a block machine dedicated for long curb block purpose, because its pallet is as long as 1150mm, can make the curbstone of maximum 1100mm length. High frequency electric motor vibration ensures optimal compaction for blocks, 15 seconds cycle time for block forming gives a maximum output for maximum profit. QT5-15 Block machine has the state-of-art vibration technology. |

|

| Photo: | Specifications: |

|

1.Mould Changeable, Hollow, Solid, Color Paver, Curbstone,etc |

| 2. Capacity per 8 hours:

a. 8 inch Block Capacity: 9600 pieces; b. 240*115*50mm solid bricks: 6144 pieces; |

|

| 3.Brick pallet size: 1150*550*30mm | |

| 4. full Machine Line Price Range:31600-51200USD | |

| 5.Factory Area: 1200-2500 m2; Workers Number:4-5; | |

| QT4-15 Stationary Hollow Block Making Machine | |

| Descriptions:

QT4-15 is a very popular automatic block machine model because of its affordable price. QT4-15 machine frame is made of high strength steel and skilled welding, to ensure the stable status for vibration motors vibrating to form blocks. QT4-15 block machine mouds frame is using high hardness 55# manganese steel, tampering head is using 16# manganese steel, after linear cutting, via carburizing and hot treatment, block mould hardness can reach 60 degree, lifespan can reach 10000 times; |

|

| Photo: | Specifications: |

|

1.Mould Changeable, Hollow, Solid, Color Paver, Curbstone,etc |

| 2. Capacity per 8 hours:

a. 8 inch Block Capacity: 7680 pieces; b. 240*115*50mm solid bricks: 57600 pieces; |

|

| 3.Brick pallet size: 960*550*25mm | |

| 4. full Machine Line Price Range:29100-46200USD | |

| 5.Factory Area: 1200-2500 m2; Workers Number:4-5; | |

| QT4-18 Simple Stationary Hollow Block Making Machine | |

| Descriptions:

QT4-18 is a simple hydraulic automatic concrete block making machine line, it is a good selling brick machine model, this machine has a good vibration performance and can equipped with face mix paver bricks, its PLC can be Siemens brand as optional, easy operation, it is one of our fist products; |

|

| Photo: | Specifications: |

|

1.Mould Changeable, Hollow, Solid, Color Paver, Curbstone,etc |

| 2. Capacity per 8 hours:

a. 8 inch Block Capacity: 6400 pieces; b. 240*115*50mm solid bricks: 41600 pieces; |

|

| 3.Brick pallet size: 880*550*25mm | |

| 4. full Machine Line Price Range:16100-29300USD | |

| 5.Factory Area: 1200-1500 m2; Workers Number:3-4; | |

| QT4-20 Manual Stationary Hollow Block Making Machine | |

| Descriptions:

QT4-20 is a manual controlled hydraulic block making machine, its configuration like mixer, host brick machine structure, vibrations , hydraulic systems, stacker machine, etc are all same with QT4-18 automatic block machine, just the operation system is different, QT4-20 is using manual control rods, while QT4-18 is automatic PLC system, because some user prefer manual type; |

|

| Photo: | Specifications: |

|

1.Mould Changeable, Hollow, Solid, Color Paver, Curbstone,etc |

| 2. Capacity per 8 hours:

a. 8 inch Block Capacity: 4320 pieces; b. 240*115*50mm solid bricks: 37440 pieces; |

|

| 3.Brick pallet size: 960*550*25mm | |

| 4. full Machine Line Price Range:18000-26000USD | |

| 5.Factory Area: 1200-1500 m2; Workers Number:3-4; | |

| QT4-25 Mechanical Stationary Hollow Block Making Machine | |

| Descriptions:

QT4-25 is also automatic concrete block machine, but it is mechanical, not hydraulic, it is simpler than QT4-18 machine, but cannot make paver bricks with color because of short of hydraulic system. This is a good brick machine line for small investment, maximum profit for the investment. |

|

| Photo: | Specifications: |

|

1.Mould Changeable, Hollow, Solid, Color Paver, Curbstone,etc |

| 2. Capacity per 8 hours:

a. 8 inch Block Capacity: 7680 pieces; b. 240*115*50mm solid bricks: 57600 pieces; |

|

| 3.Brick pallet size: 880*550*25mm | |

| 4. full Machine Line Price Range:10000-16000USD | |

| 5.Factory Area: 1200-1500 m2; Workers Number:3-4; | |

| QT4-24 Semi Automatic Stationary Hollow Block Making Machine | |

| Descriptions:

QT4-24 is a semi automatic concrete block machine, its price is not high, so it is also very good selling because of high profit return for the investment. QT4-24 brick machine is using vibration box under mould frame, vibration motor on press head, blocks are forming evenly and fast; |

|

| Photo: | Specifications: |

|

1.Mould Changeable, Hollow, Solid, Color Paver, Curbstone,etc |

| 2. Capacity per 8 hours:

a. 8 inch Block Capacity: 4428 pieces; b. 240*115*50mm solid bricks: 28782 pieces; |

|

| 3.Brick pallet size: 850*550*22mm | |

| 4. full Machine Line Price Range:6400-11000USD | |

| 5. Factory Area: 1000-1500 m2; Workers Number:3-4; | |

| QT4-28 Semi Automatic Stationary HollowBlock Making Machine | |

| Descriptions:

QT4-28 semi automatic block machine is also called one-button start block machine, because of its simple operation. QT4-28 block machine can also make different block, bricks under different brick moulds. |

|

| Photo: | Specifications: |

|

1.Mould Changeable, Hollow, Solid, Color Paver, Curbstone,etc |

| 2. Capacity per 8 hours:

a. 8 inch Block Capacity: 4114 pieces; b. 240*115*50mm solid bricks: 18514 pieces; |

|

| 3.Brick pallet size: 850*550*22mm | |

| 4. full Machine Line Price Range:7500-12000USD | |

| 5. Factory Area: 1000m2; Workers Number:3-4; | |

| QT4-35 Manual Stationary Hollow Block Making Machine | |

| Descriptions:

QT4-35 block machine is a manual type, it is developed on the QT4-40 block machine,adding a hopper on the top to make raw materials feeding more convenient. |

|

| Photo: | Specifications: |

|

1.Mould Changeable, Hollow, Solid, Color Paver, Curbstone,etc |

| 2. Capacity per 8 hours:

a. 8 inch Block Capacity: 2560 pieces; b. 240*115*50mm solid bricks: 11520 pieces; |

|

| 3.Brick pallet size: 850*550*22mm | |

| 4. full Machine Line Price Range:5100-9300USD | |

| 5. Factory Area: 600-1000 m2; Workers Number:3-4; | |

| QT4-40 Manual Stationary Hollow Block Making Machine | |

| Descriptions:

QT4-40 is a manual classic concrete block machine model, because of its cheap price, it is welcomed by many starters in the brick business industry. There is also QTJ4-40 block machine model, which is using electric switches to operate the machine instead of electric control box; and its press head mould works up and down vertically while QT4-40 press head mould works horizontally by push-pull; |

|

| Photo: | Specifications: |

|

1.Mould Changeable, Hollow, Solid, Color Paver, Curbstone,etc |

| 2. Capacity per 8 hours:

a. 8 inch Block Capacity: 2304 pieces; b. 240*115*50mm solid bricks: 10368 pieces; |

|

| 3.Brick pallet size: 850*550*22mm | |

| 4. full Machine Line Price Range:3700-8000USD | |

| 5. Factory Area: 600-1000 m2; Workers Number:3-4; | |

A few popular block-making machine suppliers are:

LINYI RAYTONE MACHINERY CO.LTD

Located in Linyi City, China. Raytone machinery offers a wide range of hollow block-making machines ranging from fully automated to completely manual. Raytone, a company that has operated since 2005, uses a plant with a layout spanning 6000 square meters. With a team of over 50 dedicated individuals, Raytone prides itself on serving clients from various parts of the world.

The company boasts a substantial international consumer base, with more than 150 members hailing from over 30 countries. Raytone’s block machines are widely sought after in major markets across Asia, Europe, the Middle East, Africa, North America, South America, Australia, and other continents.

This global presence signifies the company’s success in meeting customers’ demands worldwide and highlights its ability to cater to diverse markets across different regions.

Founded: 2005

Headquarters: China

Top products: QT4-40 Manual Block Making Machine, Semi-Automatic Block Machine – QT4-24 Model, QT4-18 Simple Automatic Concrete Block Making Machine

GM QuangongMachinery (QGM)

GM QuangongMachinery (QGM) is one of the most popular block-making suppliers. Their block-making machines are widely used internationally for their high quality and fantastic operating system. They are currently present in over 120 countries, including their country of origin: China.

The company started in 1979 and strived to keep increasing its quality and provide the utmost customer satisfaction. Beginning in 2012, they established offices in many major countries, including Russia, Saudi Arabia, Algeria, Libya, Oman, India, Indonesia, Brazil, and Mexico.

The company’s products all adhere to the standards of 6S, the ISO14001 environmental management system, and the ISO09001 quality management system. Machines have far less impact on the environment and are of greater quality.

Founded: 1979

Headquarters: China

Top products: ZENITH 940, ZENITH1500, ZENITH913, ZENITH ZN900C

Hydraform

Hydraform, founded by Jochen Kofahl in 1988, is the first brick-making business in South Africa. Kofahl envisioned creating high-quality bricks by mixing dirt with 20 percent construction cement and forming the mixture under hydraulic pressure. Following this vision, He developed a portable, on-site brick-making machine patented and sold by Hydraform.

Nine months after Hydraform was launched, Robert Plattner joined the firm and began collaborating with Kofahl. They then worked on the M1 device, specifically designed for constructing houses using Hydraform blocks.

The critical innovation of Hydraform lies in its interlocking, mortarless design. This design, supported by Agreement Certificate 96/237 granted by the CSIR in Pretoria, offers several advantages. It allows for significant cost savings in construction projects and enables the production of high-quality blocks.

Using Hydraform’s brick-making technology, construction projects can benefit from reduced costs associated with mortar, skilled labor, and time. The interlocking design of the blocks ensures stability and structural integrity without additional mortar or cement.

Overall, Hydraform’s innovative approach to brick-making has revolutionized construction practices by providing an efficient, cost-effective, and high-quality alternative to traditional brick production methods.

Founded: 1988

Headquarters: South Africa

Top products: Hydraulic Concrete Block Making Machine SE 860

Sadhana Engineering Industry

Sadhana Engineering Industries was founded by Mr. Mavis Davis, an expert in engineering equipment, and has been supplying the building industry throughout India and internationally with the highest caliber brick-making equipment. This firm is specialized because it creates specialized equipment at meager cost to satisfy the odd requirements of construction projects and structures. Their brick-making equipment can be customized to any need, an innovative way of making such complex, bulky machinery.

With its unrivaled selection of goods, the Sadhana Engineering Industry never ceases to astound the building sectors. One of their best-selling items in recent years, among others, is the concrete block Making Machine.

Founded: 1986

Headquarters: Kerala, India

Pres Makina

Pres Makina initially started by developing manual machines for making blocks and bricks. It has become one of the largest manufacturers of brick-making equipment over time globally. The company now operates three industrial facilities spread across 18,000 square meters.

Pres Makina’s success can be attributed to several factors, including its ability to provide high-quality machines, its unconventional after-sales care, and its substantial presence in Africa and the Middle East, where they manufacture its machines. By prioritizing customer satisfaction and offering comprehensive support, the company has built trust and established a competitive edge in the market.

Indeed, based on its growth, expanding facilities, and strong import portfolio, Pres Makina is well-positioned to emerge as one of the leading producers of brick-making machines in the near future. The company’s commitment to continuous improvement, evident in its expanding machinery plants and product lines, indicates a strategic focus on meeting the increasing demand for its equipment.

As the demand for brick-making machines continues to rise, Pres Makina’s expansion plans and commitment to innovation position them favorably for future growth. With their dedication to producing reliable and efficient equipment, combined with their focus on customer service, Pres Makina has the potential to solidify its position as one of the leading producers in the industry.

Founded: 1940

Headquarters: Turkey

Top products: PRO 100, PRO 100D, PRO 800D, PRO800SRS, PRO800DFA

All in all, Hollow Brick Machine are a significant piece of machinery critical for efficient and seamless construction procedures. There is a wide range of brands and companies to choose from when you are out looking for the best piece of technology, for example the companies listed above can be a good place to start if you are considering to get one for your organization or projects.

Some FAQ about the hollow block making machines:

1.How to choose a suitable Block machine model?

Choosing a suitable block machine model requires careful consideration of several factors. Here’s some points for choosing a suitable block machine:

Production Capacity: The first thing to consider is the production capacity of the machine. Different models have different capacities, and you must choose one that meets your production needs. For instance, a large-scale operation might require a machine with a higher production capacity, while a smaller operation might be better suited for a machine with a lower capacity.

Land area: the land area you have or planned for the block plant is also deciding what size block machine model you can have, because different block machine model is for different daily capacity, which need different land area, so this is also an important point for block plant;

Block shape types: if you have a clear target of which size or type block shape to make, that means your mainly products is confirmed, we can recommend as per the market demand.

Budget: your investment budget is another point for choosing the different block machine models; when client want to make an investment, but don’t know exactly the target, we can recommend the block machine model as per the budget;

Raw Material: the block machine can also be determined by the raw materials for blocks, some block machine can use fly ash, stone powder, lime etc, some machine can use earth, soil, or clay, so can choose the block machine as per its raw materials;

Power source: diesel Engine or electric motors: some areas is short of power, so the diesel block machine can be a choice;

Mobile block machine or stationary block machine; as per the customer need, the mobile block machine is working on concrete ground, its advantages is not using brick pallets, the brick pallets is also a big cost in the block making.

Other concern:

Ease of Operation: The block machine you choose should be easy to use. Look for models that have user-friendly interfaces and intuitive controls.

Maintenance Requirements: Some machines require more maintenance than others. Choose a model that is easy to maintain and comes with a good warranty.

Remember, the right block machine for you will depend on your specific requirements. It’s always a good idea to do thorough research and consult with experts before making a purchase.

2.What is the shipping method of Block machine?

For manual or smaller block machine, we can pack them into wooden case; to send to the client by Less than a container , which is LCL, sometimes the client don’t want to take the wooden case packing cost for the manual block machine, it is also okay, because block machine is heavy and strong product, it can be shipped without packing; and for full automatic block machine, we need to load into 20 feet container or 40 feet dry container, then transport the goods to our local Qingdao port, then they are shipped to the destination port by sea;

3.Are there any use cases for Block machine to share

Raytone Block machines have many successful use cases across the globe. These machines, versatile and technologically advanced, create durable and shock-resistant blocks. They are eco-friendly, utilizing waste solids and hydraulic systems for reliable operation. The machines are adaptable to a wide range of raw materials, making them highly efficient and cost-effective. They offer various models and sizes, suitable for different block specifications. This versatility and performance have led to the successful implementation of these machines in diverse construction scenarios.

The below is some of our successful using case in different countries:

QT4-15 Automatic block machine set up in Djibouti in 2016

In the year of 2016, Raytone Company sold his first QT4-15 automatic block machine to an transnational corporation, which is based in UAE, but the concrete block plant is set up in Djibouti.

In the year of 2016, Raytone company got an inquiry from Mr. Zerihun from Ethiopia, he inquired about the automatic hollow block making machine, we recommended him the QT4-15D block machine model, the quotation is including full set of QT4-15 block plant, bamboo brick pallets and one set diesel generator; after we made the PI to Mr. Zerihun, then we start the long time waiting; because he needs to make loan from the the bank, and Ethiopia payment is only the Letter of Credit, and their work efficiency is very slow; then after two years time, in the year of 2018, we are contacted by someone from Ethiopia Development Bank, after our discussion and provide them some documents, the bank issued us the Letter of Credit at sight; we made the delivery within the LC valid time, the QT4-15 full plant is loaded by 3 units of 40 feet high container; and after the shipped block machine is received by Mr. Zerihun, we also dispatched our technician for block machine installation, now the automatic hollow block plant is running well.

We also have QT4-18 simple automatic block making machine 2018 in Sri Lanka , Bangladesh QT4-15 automatic brick making machine; Nepal QT4-18 Brick Machine: Revolutionizing Automatic Block Making; QT4-18 automatic block making machine in Senegal; The QT12-15 Fully Automatic Concrete Block Making Machine to Zambia; Philippines Client Chose The QT4-15S Automatic Block Machine;

4.What supporting equipment does Block machine need during the production process?

Block machine production requires several pieces of supporting equipment to ensure smooth and efficient operations. This equipment includes wheel loader to load raw materials into the concrete batching machine; concrete batching machine, which are used to prepare the raw materials like sand and gravel needed for block production;

the concrete mixer, which is used to mix different raw materials;

Machines for finishing concrete blocks are also essential; these include block stacking machine, to stack finished block one pallet by one pallet; need diesel forklift to carry the stacked pallets to the curing area; also the brick pallet is a very important part for block forming as a tray;

5.About hollow block machine customization services

There is many customization services for block machine; the block machine configuration equipment can be customized, for the batching machine hopper quantity, mixer capacity, even block machine can be customized as per the block size needed; the electric motor brand can be optional, for example the Siemens brand motors; the voltage for motors can be customized as per different country’s different voltage; the block moulds are customized.

6.About hollow block machine payment method

the block machine payment method is 30% by TT, balance before shipment; or LC at sight is acceptable; some other payment method can be negotiable;

7.About hollow block machine warranty

RAYTONE block machine warranty is 2 years since shipment, but we provide the technical support all the machine life;