- 20

- Dec

concrete t block machine

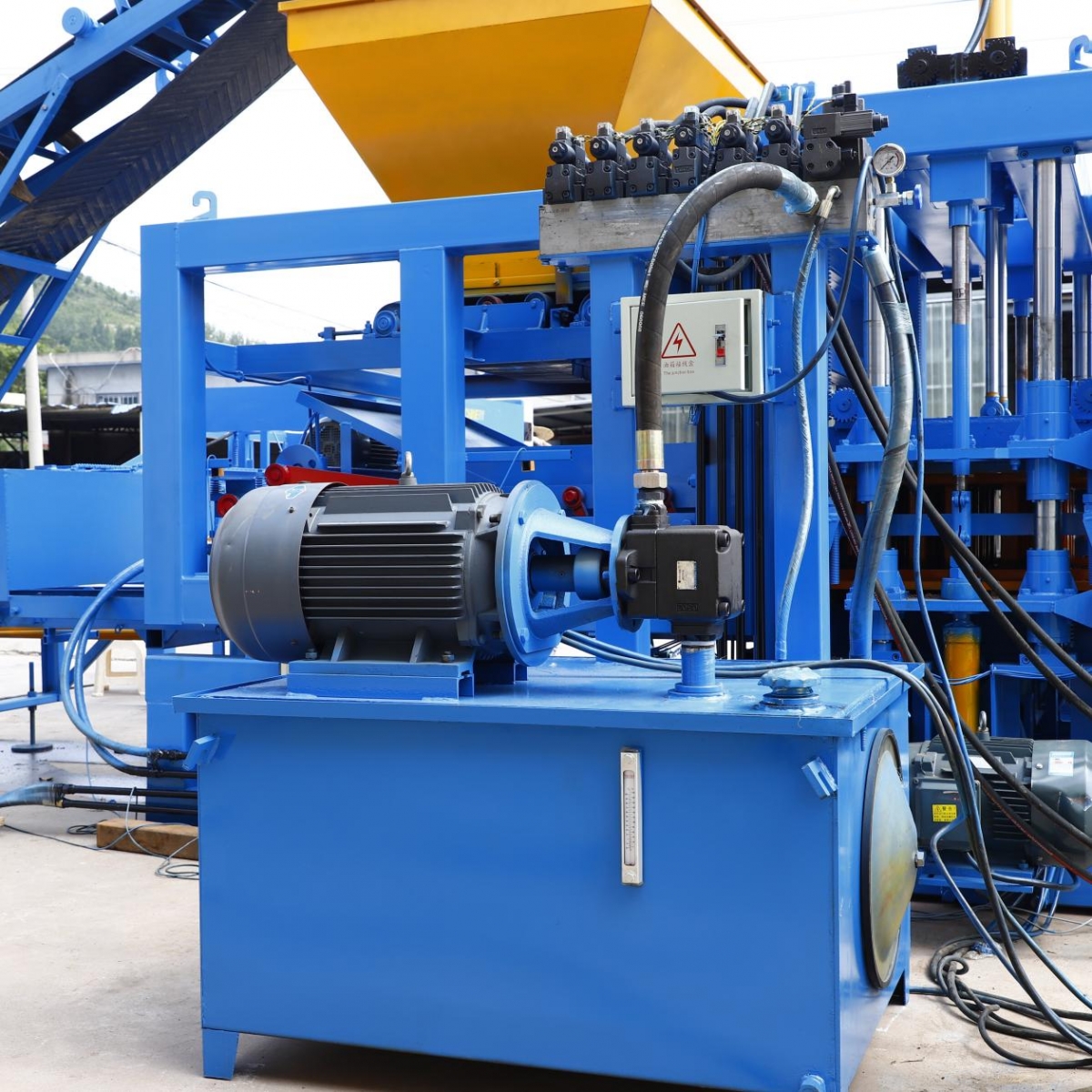

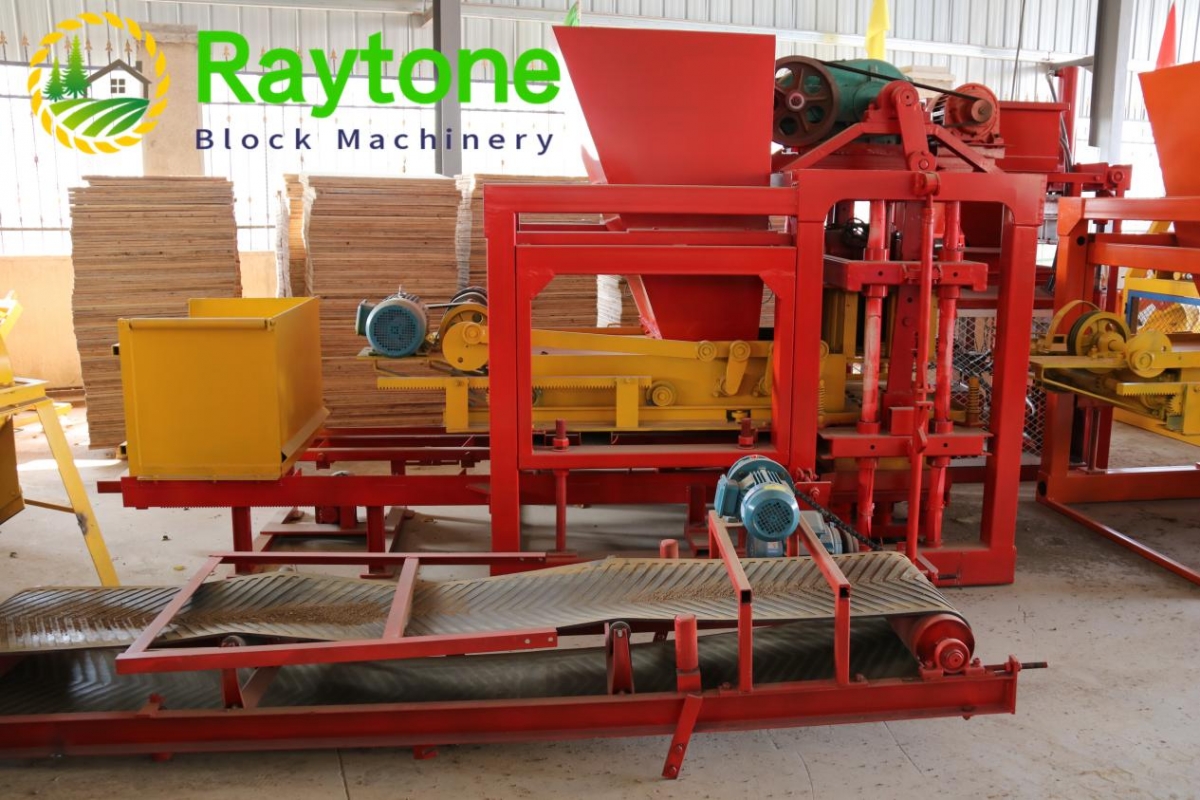

Our concrete t block machine are suitable for producing different types of blocks such as hollow, solid, Drainage channel blocks, and paving blocks. They utilize hydraulic pressure to compress raw materials such as sand, cement, and gravel to form strong and durable concrete blocks. The blocks produced by our machines have accurate dimensions, smooth surfaces, and can withstand high pressures, making them perfect for building walls, fences, Drainage channel blocks, and other structures.

Equipped with a powerful motor and hydraulic system, the Block Machine is capable of producing up to 9812 bricks per hour. It also features an automatic feeding system, allowing for continuous production without any interruptions. The machine has a PLC control system that ensures precise and accurate production, while also making it user-friendly and easy to operate.

concrete t block machine is a type of equipment used for producing concrete blocks in various shapes and sizes. There are different models of concrete t block machines available in the market, each with its own unique features and capabilities.

QT6-15 Block Making Machine, which is designed for high production and efficiency. This machine is equipped with a large capacity pallet, allowing it to produce six blocks in one cycle. It also has a high pressure hydraulic system, ensuring strong and stable block compression. The QT6-15 is designed with advanced nozzle and mold vibration technology, resulting in precise and high-quality block production.

QT5-15 Concrete Block Molding Machine, which is suitable for producing various types of concrete blocks, including hollow, solid, and interlocking blocks. It has a powerful vibration system and a multi-source vibration of 360 degrees, which ensures uniform and strong block density. The machine also has a high-speed hydraulic system, allowing for quick and efficient block production.

Both models mentioned above have automatic control systems with PLC and touch screen interface, making it easy to operate and adjust the machine settings. They also have customizable features, such as different molds and block sizes, to cater to various construction needs.

In terms of parameters, the QT6-15 has a production capacity of 8640-11520 blocks per shift, while the QT5-15 can produce 7680-10240 blocks per shift. Both models have a power rating of 27.5 kW and require a voltage of 380V. They also have a weight of approximately 14-15 tons and a compact design for ease of transportation and installation.

| Size (mm) | Qty/mould | mould cycle (s) | capacity per hour | daily capacity |

| hollow 400*200*200 | 6 | 20-25 s | 850-1100 | 7303-8800 |

| hollow 400*150*200 | 7 | 20-25 s | 1000-1300 | 8253-10400 |

| hollow 400*100*200 | 18 | 20-25 s | 1200-1400 | 8426-11200 |

The Environmental Benefits of Block Machine Designs

concrete t block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.Is a concrete t block machine easy to operate?

3.What is the level of precision and accuracy in the production of blocks with a concrete t block machine?

4.About concrete t block machine customization services

5.Are there safety precautions that need to be taken while operating a concrete t block machine?

6.What is the cost-effectiveness of using a concrete t block machine?

7.About concrete t block machine production management system

8.Can a concrete t block machine be used in disaster relief or emergency situations?

9.Does a concrete t block machine require a specific type of raw material?

10.What is the production capacity of a concrete t block machine?

11.Can a concrete t block machine produce blocks with varying levels of compressive strength?

12.Does a concrete t block machine require specialized training to operate?

13.About concrete t block machine production capacity

14.About concrete t block machine quality system

15.What are the key components of a concrete t block machine?

1.About concrete t block machine payment method

Block machine payment methods vary depending on the manufacturer and the type of machine. Some common payment methods include cash, credit cards, PayPal, wire transfers, and cryptocurrency. Some manufacturers may also offer financing options or leasing options.

2.Is a concrete t block machine easy to operate?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

Yes, most block machines are designed to be easy to operate. Many modern block machines are automated and require minimal operator input. However, some block machines may require more operator input and knowledge to operate correctly.

3.What is the level of precision and accuracy in the production of blocks with a concrete t block machine?

The level of precision and accuracy in the production of blocks with a Block machine depends on the type of machine and the quality of the components used. Generally, modern block machines are capable of producing blocks with a high degree of accuracy and precision. The accuracy of the blocks produced can be further improved by using higher quality components and calibrating the machine regularly.

4.About concrete t block machine customization services

Block machine customization services are designed to help businesses create custom-made block machines that are tailored to their specific needs. These services can include the design and engineering of the machine, the fabrication of the components, and the installation and maintenance of the machine. The customization services can also include the development of software and hardware to control the machine, as well as the integration of the machine into existing production lines. The customization services can also include the development of custom-made parts and components for the machine, as well as the development of custom-made tools and fixtures for the machine.

5.Are there safety precautions that need to be taken while operating a concrete t block machine?

As one of the top concrete t block machine manufacturers in China, we take this very seriously.

Yes, there are several safety precautions that should be taken when operating a block machine. These include:

1. Wear appropriate safety gear, such as safety glasses, gloves, and a hard hat.

2. Make sure the machine is properly grounded and that all electrical connections are secure.

3. Ensure that the machine is properly lubricated and that all moving parts are in good working order.

4. Keep the work area clean and free of debris.

5. Make sure that all guards and safety devices are in place and functioning properly.

6. Make sure that all operators are properly trained and familiar with the machine’s operation.

7. Make sure that all operators are aware of the potential hazards associated with the machine and take the necessary precautions to avoid them.

8. Make sure that all operators are aware of the emergency stop button and know how to use it in case of an emergency.

6.What is the cost-effectiveness of using a concrete t block machine?

The cost-effectiveness of using a block machine depends on the type of block machine being used, the size of the project, and the amount of labor required. Generally, block machines are more cost-effective than traditional methods of block production, as they require less labor and can produce more blocks in a shorter amount of time. Additionally, block machines can produce blocks with a higher degree of accuracy and uniformity than traditional methods, which can result in a higher quality product.

7.About concrete t block machine production management system

The Block machine production management system is a software solution designed to help businesses manage the production of concrete blocks. It provides a comprehensive set of tools to help businesses track and manage the production process from start to finish. The system can be used to monitor production, track inventory, manage orders, and generate reports. It also provides features such as scheduling, cost tracking, and quality control. The system is designed to be user-friendly and can be customized to meet the specific needs of each business.

8.Can a concrete t block machine be used in disaster relief or emergency situations?

Yes, block machines can be used in disaster relief or emergency situations. Block machines can be used to quickly construct temporary shelters, walls, and other structures that can provide protection and shelter for those affected by a disaster. Block machines can also be used to create roads and pathways for emergency vehicles and personnel to access affected areas.

9.Does a concrete t block machine require a specific type of raw material?

Our concrete t block machine products undergo strict quality control to ensure customer satisfaction.

Yes, a block machine typically requires a specific type of raw material, such as sand, gravel, cement, and water. Depending on the type of block machine, other materials may also be required.

10.What is the production capacity of a concrete t block machine?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

The production capacity of a block machine depends on the size and type of block being produced. Generally, a block machine can produce between 1,000 and 8,000 blocks per hour.

11.Can a concrete t block machine produce blocks with varying levels of compressive strength?

Yes, a block machine can produce blocks with varying levels of compressive strength. This is done by adjusting the amount of pressure applied to the blocks during the manufacturing process. The amount of pressure applied can be adjusted to produce blocks with different levels of compressive strength.

12.Does a concrete t block machine require specialized training to operate?

We continuously upgrade our skills and knowledge to adapt to changing concrete t block machine market needs.

Yes, a block machine typically requires specialized training to operate. Depending on the type of block machine, the operator may need to be trained in the use of the machine, safety protocols, and other related topics.

13.About concrete t block machine production capacity

The production capacity of a block machine depends on the size of the blocks it is producing, the type of material being used, and the speed of the machine. Generally, a block machine can produce between 500 and 5,000 blocks per hour.

14.About concrete t block machine quality system

A block machine quality system is a set of procedures and processes that are used to ensure that the block machines manufactured by a company meet the highest standards of quality. The system includes the use of quality control measures such as inspections, testing, and documentation to ensure that the block machines are safe and reliable. The system also includes the use of quality assurance measures such as training, auditing, and corrective action plans to ensure that the block machines are consistently meeting the required standards. The system also includes the use of preventive maintenance measures such as regular maintenance and repairs to ensure that the block machines are operating at peak efficiency.

15.What are the key components of a concrete t block machine?

We are a professional concrete t block machine company dedicated to providing high quality products and services.

1. Concrete Mixer: This is used to mix the concrete and other materials used in the block production process.

2. Block Mould: This is the mould used to shape the blocks.

3. Hydraulic Press: This is used to press the blocks into shape.

4. Palletizing System: This is used to move the blocks from the press to the curing area.

5. Curing Area: This is where the blocks are cured and allowed to dry.

6. Packaging System: This is used to package the blocks for shipping.