- 21

- Dec

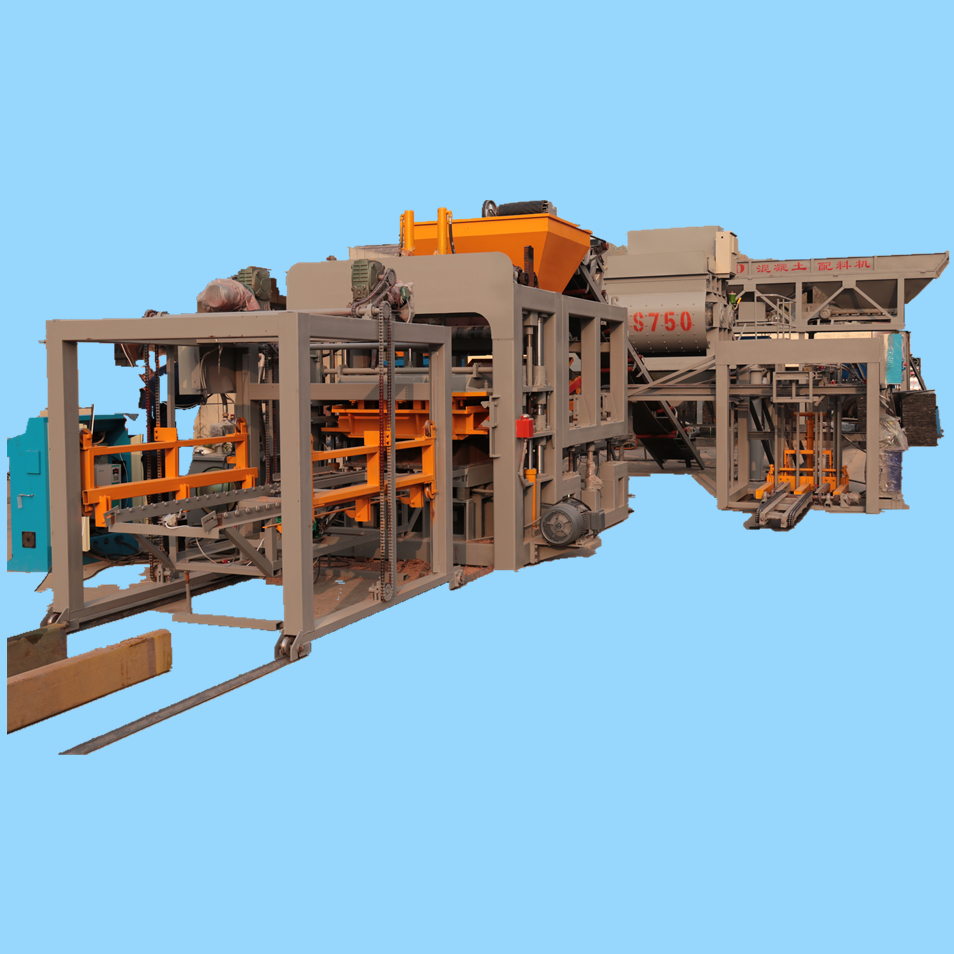

ibm 1000 4 block machine

One of the key features of our ibm 1000 4 block machine

is its user-friendly design. It is equipped with a computerized control system, making it easy to operate and monitor. The control panel allows for precision and flexibility in adjusting the production process, ensuring consistent and high-quality blocks every time.

In addition, our block machines are also environmentally friendly. They have a low carbon footprint, consume minimal amounts of energy, and produce minimal waste, making them an ideal choice for sustainable construction and Airport runway construction.

Block Machine Technical Parameters:

1. Production capacity: up to 11250 blocks per hour

2. Mold configuration: customizable for different block types and sizes

3. Control panel: user-friendly interface for block thickness and density adjustments

4. Hydraulic system: ensures consistent and stable pressure

5. Service life: at least 14 years

6. Energy efficiency: minimal power consumption

7. Installation and training: turnkey package provided by our experts

The ibm 1000 4 block machine comes in various models and configurations. Some popular models include the QMJ4-35A, QT4-15, and QT6-15. These machines are designed for different production capacities and can produce a range of concrete blocks such as hollow blocks, solid blocks, and paving blocks.

The QMJ4-35A is a manual model with a production capacity of 2428-3000 blocks per day. It has a power of 9.7 kW and can produce blocks in various sizes with a maximum length of 390mm. The QT4-15 is a semi-automatic model with a production capacity of 4000-7548 blocks per day. It is equipped with a 21.5 kW power and can produce blocks in different sizes up to 390mm in length. The QT6-15 is a fully automatic model with a production capacity of 8819-10000 blocks per day. It has a power of 27.5 kW and can produce blocks in various sizes up to 480mm in length.

| land area | 284 Square Meters | Water Consumption | 2.4 T/day |

| Workshop area | 75 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 3 workers | Power Consumption | 26.5 KW*8 Hours=212 KWH; |

| Cement Consumption | 7.27 Tons per day | Sand consumption | 28.9 tons per day |

| Crushed stones consumption | 39.02 tons per day |

The Environmental Benefits of Block Machine Designs

ibm 1000 4 block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.What is the cost-effectiveness of using a ibm 1000 4 block machine?

3.Are there pre-programmed block designs available for a ibm 1000 4 block machine?

4.About ibm 1000 4 block machine production capacity

5.What is the lifespan of a ibm 1000 4 block machine?

6.How does the weight of a block affect transportation and storage?

7.How does the cost of a ibm 1000 4 block machine compare to traditional building materials?

8.Can a ibm 1000 4 block machine be used to produce other building materials besides blocks?

9.Are there any noise or vibration concerns with a ibm 1000 4 block machine?

10.About ibm 1000 4 block machine raw material procurement system

11.What are the maintenance costs associated with running a ibm 1000 4 block machine?

12.How long does it take to produce a block with a ibm 1000 4 block machine?

13.About ibm 1000 4 block machine raw materials

14.Can a ibm 1000 4 block machine produce blocks of varying shapes?

15.About ibm 1000 4 block machine customization services

16.Is it possible to produce decorative blocks with a ibm 1000 4 block machine?

1.Can a ibm 1000 4 block machine be used for both indoor and outdoor construction projects?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

Yes, a block machine can be used for both indoor and outdoor construction projects. However, the type of block machine used will depend on the specific project requirements. For example, a block machine designed for outdoor projects may be more powerful and durable than one designed for indoor projects.

2.What is the cost-effectiveness of using a ibm 1000 4 block machine?

The cost-effectiveness of using a block machine depends on the type of block machine being used, the size of the project, and the amount of labor required. Generally, block machines are more cost-effective than traditional methods of block production, as they require less labor and can produce more blocks in a shorter amount of time. Additionally, block machines can produce blocks with a higher degree of accuracy and uniformity than traditional methods, which can result in a higher quality product.

3.Are there pre-programmed block designs available for a ibm 1000 4 block machine?

We operate our ibm 1000 4 block machine business with integrity and honesty.

Yes, some block machines come with pre-programmed block designs. However, many block machines also allow users to create their own custom designs.

4.About ibm 1000 4 block machine production capacity

The production capacity of a block machine depends on the size of the blocks it is producing, the type of material being used, and the speed of the machine. Generally, a block machine can produce between 500 and 5,000 blocks per hour.

5.What is the lifespan of a ibm 1000 4 block machine?

Our products & services cover a wide range of areas and meet the needs of different fields.

The lifespan of a block machine can vary depending on the type of machine and how it is used. Generally, block machines can last anywhere from 10 to 20 years with proper maintenance.

6.How does the weight of a block affect transportation and storage?

The weight of a block affects transportation and storage in several ways. Heavier blocks require more energy to move and can be more difficult to transport. They also require more space for storage, as they take up more room than lighter blocks. Additionally, heavier blocks may require more specialized equipment for transportation and storage, such as forklifts or cranes.

7.How does the cost of a ibm 1000 4 block machine compare to traditional building materials?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

The cost of a block machine is typically much higher than traditional building materials. Block machines are typically used to produce large quantities of blocks, which can be expensive to purchase in bulk. Additionally, block machines require specialized equipment and expertise to operate, which can add to the cost.

8.Can a ibm 1000 4 block machine be used to produce other building materials besides blocks?

Yes, a block machine can be used to produce other building materials such as pavers, bricks, tiles, and even roof tiles.

9.Are there any noise or vibration concerns with a ibm 1000 4 block machine?

Yes, noise and vibration are common concerns with block machines. The noise and vibration levels can vary depending on the type of machine and the materials being used. It is important to ensure that the machine is properly maintained and that the operator is properly trained to reduce the risk of excessive noise and vibration.

10.About ibm 1000 4 block machine raw material procurement system

A block machine raw material procurement system is a software solution designed to streamline the process of procuring raw materials for the production of concrete blocks. The system automates the process of ordering, tracking, and managing the delivery of raw materials, allowing for greater efficiency and cost savings. The system also provides detailed reporting and analytics to help manufacturers better understand their supply chain and make informed decisions about their raw material procurement.

11.What are the maintenance costs associated with running a ibm 1000 4 block machine?

The maintenance costs associated with running a Block machine will vary depending on the type of machine and its age. Generally, maintenance costs can include regular oil changes, filter replacements, lubrication, and other routine maintenance. Additionally, more complex repairs such as replacing worn parts or repairing electrical components may be necessary. Depending on the machine, these repairs can be costly.

12.How long does it take to produce a block with a ibm 1000 4 block machine?

Our mission is to provide customers with the best solutions for ibm 1000 4 block machine.

The time it takes to produce a block with a block machine depends on the size and type of block being produced. Generally, it takes between 10 and 30 seconds to produce a single block.

13.About ibm 1000 4 block machine raw materials

Block machine raw materials are typically made from a combination of cement, sand, gravel, and water. The exact proportions of each material used will vary depending on the type of block being made. The raw materials are mixed together in a concrete mixer and then poured into a block machine, which forms the blocks. The blocks are then cured and hardened before being ready for use.

14.Can a ibm 1000 4 block machine produce blocks of varying shapes?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, a block machine can produce blocks of varying shapes. Block machines are designed to produce blocks of different sizes and shapes, depending on the type of block machine and the type of block being produced. Some block machines are capable of producing blocks with complex shapes, such as interlocking blocks, while others are limited to producing blocks with basic shapes, such as rectangular blocks.

15.About ibm 1000 4 block machine customization services

Block machine customization services are designed to help businesses create custom-made block machines that are tailored to their specific needs. These services can include the design and engineering of the machine, the fabrication of the components, and the installation and maintenance of the machine. The customization services can also include the development of software and hardware to control the machine, as well as the integration of the machine into existing production lines. The customization services can also include the development of custom-made parts and components for the machine, as well as the development of custom-made tools and fixtures for the machine.

16.Is it possible to produce decorative blocks with a ibm 1000 4 block machine?

Being one of the top ibm 1000 4 block machine manufacturers in China, We attach great importance to this detail.

Yes, it is possible to produce decorative blocks with a block machine. Block machines are designed to produce a variety of blocks, including decorative blocks. Decorative blocks can be made in a variety of shapes, sizes, and colors, and can be used for a variety of applications, such as retaining walls, garden edging, and more.