- 20

- Dec

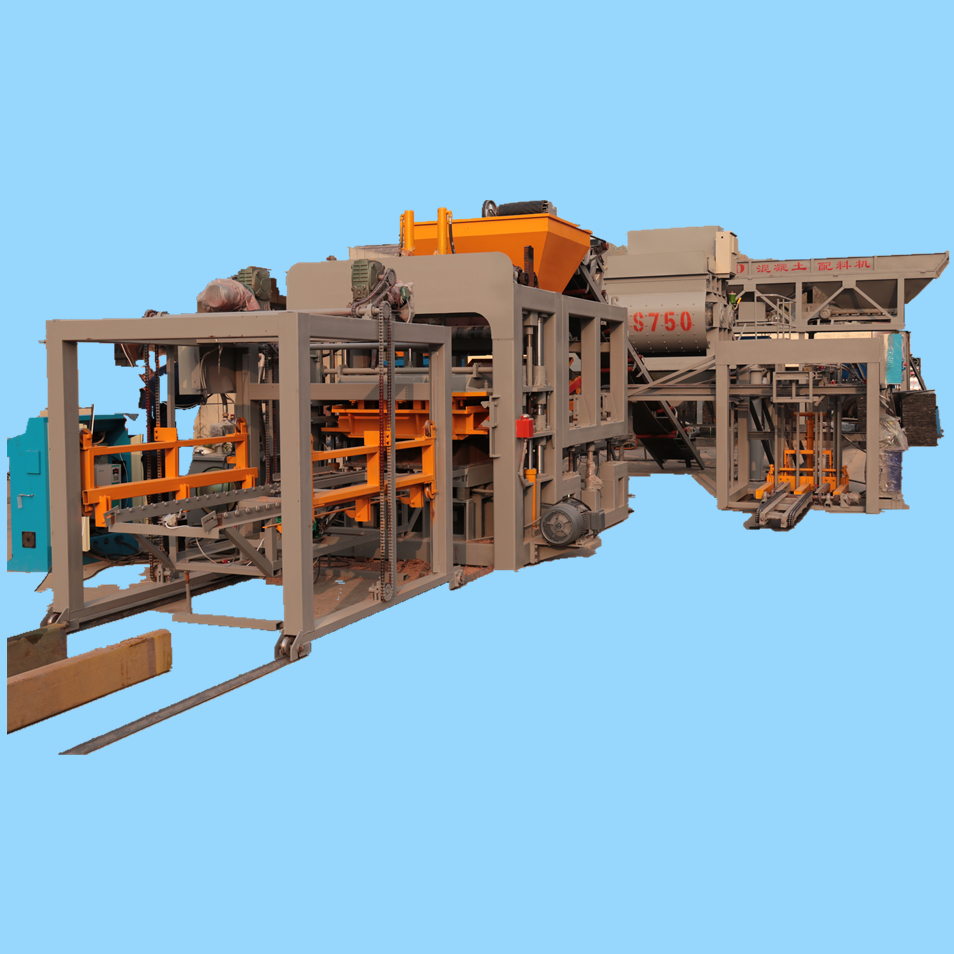

customized multi-functional hollow block machine

customized multi-functional hollow block machine is a versatile and efficient machine designed to produce high-quality concrete blocks. It is a must-have machine for construction and building companies as it can streamline the block production process and reduce labor costs.

At our manufacturing company, we take great pride in producing state-of-the-art block machines that are of the highest quality and durability. Our machines are made with the latest technology and assembled by a team of highly skilled technicians.

Block Machine Technical Parameters:

1. Production capacity: up to 8564 blocks per hour

2. Mold configuration: customizable for different block types and sizes

3. Control panel: user-friendly interface for block thickness and density adjustments

4. Hydraulic system: ensures consistent and stable pressure

5. Service life: at least 14 years

6. Energy efficiency: minimal power consumption

7. Installation and training: turnkey package provided by our experts

The customized multi-functional hollow block machine comes in various models and configurations. Some popular models include the QMJ4-35A, QT4-15, and QT6-15. These machines are designed for different production capacities and can produce a range of concrete blocks such as hollow blocks, solid blocks, and paving blocks.

The QMJ4-35A is a manual model with a production capacity of 2410-3000 blocks per day. It has a power of 9.7 kW and can produce blocks in various sizes with a maximum length of 390mm. The QT4-15 is a semi-automatic model with a production capacity of 4000-7414 blocks per day. It is equipped with a 21.5 kW power and can produce blocks in different sizes up to 390mm in length. The QT6-15 is a fully automatic model with a production capacity of 8450-10000 blocks per day. It has a power of 27.5 kW and can produce blocks in various sizes up to 480mm in length.

| Size (mm) | Qty/mould | mould cycle (s) | capacity per hour | daily capacity |

| hollow 400*200*200 | 6 | 20-25 s | 850-1100 | 6903-8800 |

| hollow 400*150*200 | 7 | 20-25 s | 1000-1300 | 9471-10400 |

| hollow 400*100*200 | 18 | 20-25 s | 1200-1400 | 8371-11200 |

Block Machines Redefining Building Standards

customized multi-functional hollow block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.About customized multi-functional hollow block machine overseas warehouse

3.Can a customized multi-functional hollow block machine be used in combination with other building techniques?

4.What is the lifespan of a customized multi-functional hollow block machine?

5.Can a customized multi-functional hollow block machine be used to produce other building materials besides blocks?

6.About customized multi-functional hollow block machine technology

7.About customized multi-functional hollow block machine raw material procurement system

8.Can a customized multi-functional hollow block machine produce blocks with varying levels of compressive strength?

9.Can a customized multi-functional hollow block machine be operated by one person?

10.What materials are commonly used in a customized multi-functional hollow block machine?

11.Can a customized multi-functional hollow block machine be used for large scale production?

12.Can a customized multi-functional hollow block machine be easily repaired in case of breakdown?

1.How does the weight of a block affect transportation and storage?

The weight of a block affects transportation and storage in several ways. Heavier blocks require more energy to move and can be more difficult to transport. They also require more space for storage, as they take up more room than lighter blocks. Additionally, heavier blocks may require more specialized equipment for transportation and storage, such as forklifts or cranes.

2.About customized multi-functional hollow block machine overseas warehouse

Block machine overseas warehouses are warehouses located in different countries around the world that store and distribute block machines. These warehouses are used to store and ship block machines to customers in different countries. The warehouses are typically owned and operated by the block machine manufacturer or distributor. They are responsible for ensuring that the block machines are properly stored and shipped to customers in a timely manner.

3.Can a customized multi-functional hollow block machine be used in combination with other building techniques?

Yes, a block machine can be used in combination with other building techniques. For example, a block machine can be used to create the walls of a building, while other building techniques such as steel framing, masonry, and wood framing can be used to create the roof and other structural elements. Additionally, a block machine can be used to create decorative elements such as columns, arches, and other architectural features.

4.What is the lifespan of a customized multi-functional hollow block machine?

Our products & services cover a wide range of areas and meet the needs of different fields.

The lifespan of a block machine can vary depending on the type of machine and how it is used. Generally, block machines can last anywhere from 10 to 20 years with proper maintenance.

5.Can a customized multi-functional hollow block machine be used to produce other building materials besides blocks?

Yes, a block machine can be used to produce other building materials such as pavers, bricks, tiles, and even roof tiles.

6.About customized multi-functional hollow block machine technology

Block machine technology is a type of construction technology that is used to produce concrete blocks. It is a process that involves mixing cement, sand, and water to form a concrete mixture, which is then poured into a mold and compressed to form a block. The blocks are then cured and hardened before being used in construction projects. Block machine technology has been used for centuries to create strong and durable structures. It is a cost-effective and efficient way to build structures that are both aesthetically pleasing and structurally sound.

7.About customized multi-functional hollow block machine raw material procurement system

A block machine raw material procurement system is a software solution designed to streamline the process of procuring raw materials for the production of concrete blocks. The system automates the process of ordering, tracking, and managing the delivery of raw materials, allowing for greater efficiency and cost savings. The system also provides detailed reporting and analytics to help manufacturers better understand their supply chain and make informed decisions about their raw material procurement.

8.Can a customized multi-functional hollow block machine produce blocks with varying levels of compressive strength?

Yes, a block machine can produce blocks with varying levels of compressive strength. This is done by adjusting the amount of pressure applied to the blocks during the manufacturing process. The amount of pressure applied can be adjusted to produce blocks with different levels of compressive strength.

9.Can a customized multi-functional hollow block machine be operated by one person?

Yes, a block machine can be operated by one person. However, it is recommended that two people operate the machine for safety reasons.

10.What materials are commonly used in a customized multi-functional hollow block machine?

Our mission is to provide customers with the best solutions for customized multi-functional hollow block machine.

Common materials used in block machines include concrete, sand, gravel, cement, and water. Depending on the type of block being made, other materials such as steel, plastic, and wood may also be used.

11.Can a customized multi-functional hollow block machine be used for large scale production?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, block machines can be used for large scale production. Block machines are designed to produce large quantities of concrete blocks in a short amount of time. They are typically used in the construction industry to produce blocks for walls, foundations, and other structures.

12.Can a customized multi-functional hollow block machine be easily repaired in case of breakdown?

Yes, a block machine can be easily repaired in case of breakdown. Depending on the type of block machine, the repair process may involve replacing parts, cleaning and lubricating components, or adjusting settings. In some cases, a technician may need to be called in to diagnose and repair the machine.