- 20

- Dec

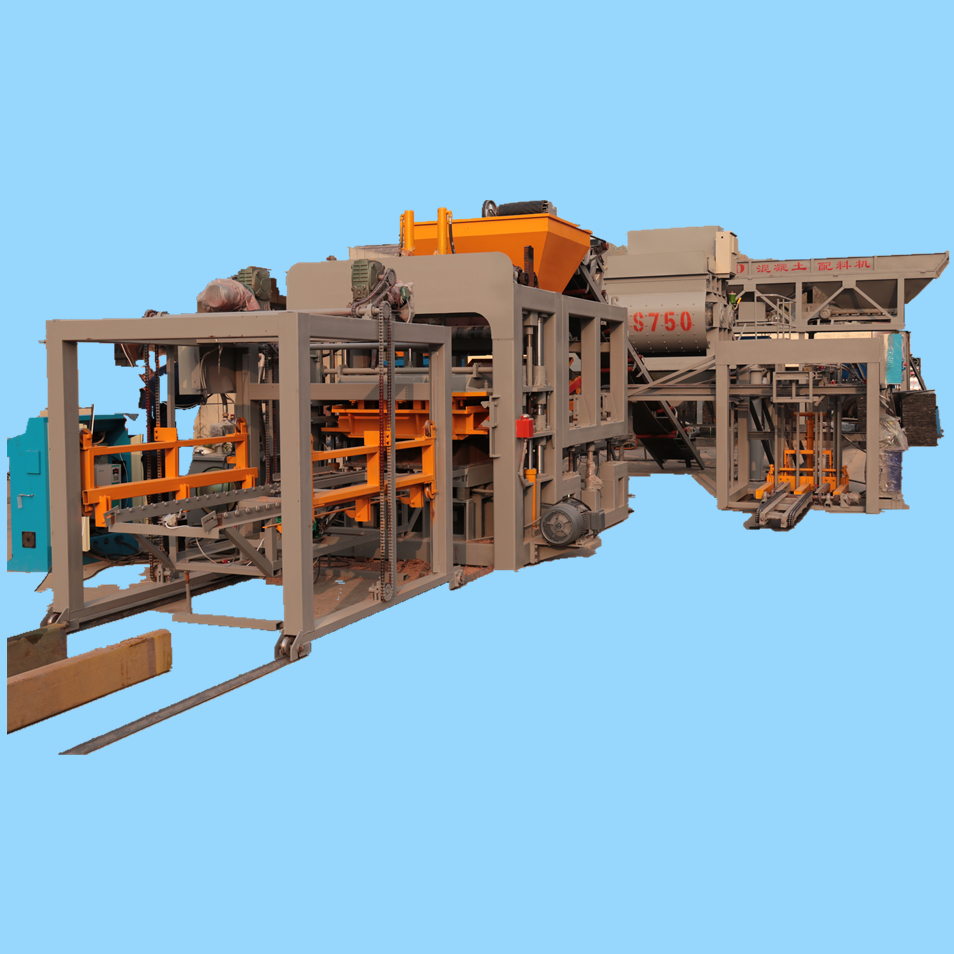

egg laying concrete block machine

One of our signature products is the fully automatic egg laying concrete block machine, capable of producing different types of blocks, such as hollow blocks, solid blocks, Grass paversand paving blocks. This machine is highly automated, making it easy to operate and maintain while achieving a high output rate. It is also equipped with a pallet feeder, brick conveyor, and hydraulic system for efficient handling and production.

For those in need of a more versatile machine, we also offer the semi-automatic block machine, which allows for manual control and adjustment of operations. This machine is ideal for small-scale production and can produce various sizes and shapes of concrete blocks.

Block Machine Technical Specifications:

1. Power: 394V-406V, 67-54Hz, 3 phase

2. Production Capacity: 5414-7782 blocks per hour

3. Block Types: Hollow blocks, solid blocks, paver blocks, and more

4. Block Size: Customizable according to customer needs

5. Weight: Approx. 1851 kg

6. Dimensions: 2043x1322x3060 mm

Our block making machines are the top solution for all your Drainage channel blocks production needs. With its high productivity, durability and versatility, it is the perfect choice for large-scale industrial manufacturing. Contact us today to learn more and start your block production process!

One of the most popular models is the fully automatic egg laying concrete block machine, which is equipped with advanced technology and can produce blocks of various shapes and sizes with high precision. It has a production capacity of up to 10,000 blocks per hour and can be operated by just one person.

Another model is the semi-automatic egg laying concrete block machine, which also has a high production capacity of up to 8,000 blocks per hour. It requires some manual labor, but still offers a faster and hassle-free production process.

The manual egg laying concrete block machine is a budget-friendly option for producing blocks on a smaller scale. It has a production capacity of up to 4,000 blocks per hour and requires more manual labor compared to the other models.

All the models of the egg laying concrete block machine are equipped with high-quality material and components, ensuring durability and long-lasting performance. They also have adjustable parameters for block size, thickness, and density, allowing for customization according to specific requirements.

| land area | 259 Square Meters | Water Consumption | 2.4 T/day |

| Workshop area | 63 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 3 workers | Power Consumption | 26.5 KW*8 Hours=212 KWH; |

| Cement Consumption | 5.09 Tons per day | Sand consumption | 30.5 tons per day |

| Crushed stones consumption | 30.74 tons per day |

How Block Machines Adapt to Any Project

egg laying concrete block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.How does the cost of a egg laying concrete block machine compare to traditional building materials?

3.Is a egg laying concrete block machine easy to operate?

4.Can a egg laying concrete block machine be used to produce other building materials besides blocks?

5.How does a egg laying concrete block machine work?

6.Are spare parts readily available for a egg laying concrete block machine?

7.Can a egg laying concrete block machine be operated by one person?

8.Can a egg laying concrete block machine be used for multiple types of construction projects?

9.About egg laying concrete block machine delivery date

10.How does climate affect the production of blocks with a egg laying concrete block machine?

11.Are there any specific safety regulations for operating a egg laying concrete block machine?

12.Can a egg laying concrete block machine be used in areas with limited access to electricity?

13.Are there any environmental concerns related to the production of blocks with a egg laying concrete block machine?

1.Can a egg laying concrete block machine produce eco-friendly blocks?

As one of the egg laying concrete block machine market leaders, we are known for innovation and reliability.

Yes, a block machine can produce eco-friendly blocks. Many block machines are designed to produce blocks that are made from recycled materials, such as plastic, glass, and other materials. These blocks are often referred to as green blocks” and are becoming increasingly popular as a sustainable building material.”

2.How does the cost of a egg laying concrete block machine compare to traditional building materials?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

The cost of a block machine is typically much higher than traditional building materials. Block machines are typically used to produce large quantities of blocks, which can be expensive to purchase in bulk. Additionally, block machines require specialized equipment and expertise to operate, which can add to the cost.

3.Is a egg laying concrete block machine easy to operate?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

Yes, most block machines are designed to be easy to operate. Many modern block machines are automated and require minimal operator input. However, some block machines may require more operator input and knowledge to operate correctly.

4.Can a egg laying concrete block machine be used to produce other building materials besides blocks?

Yes, a block machine can be used to produce other building materials such as pavers, bricks, tiles, and even roof tiles.

5.How does a egg laying concrete block machine work?

We continuously upgrade our skills and knowledge to adapt to changing egg laying concrete block machine market needs.

A block machine is a machine used to produce concrete blocks for use in construction projects. The machine works by using a combination of vibration, pressure, and heat to form the blocks. The blocks are formed in a mold, which is filled with a mixture of sand, cement, and water. The mold is then placed in the block machine, which vibrates and applies pressure to the mixture to form the blocks. The blocks are then removed from the mold and allowed to dry before being used in construction projects.

6.Are spare parts readily available for a egg laying concrete block machine?

egg laying concrete block machine is not a product only, but also can help you comes to money-making.

Yes, spare parts for block machines are readily available. Many manufacturers offer spare parts for their machines, and there are also third-party suppliers that offer spare parts for a variety of block machines.

7.Can a egg laying concrete block machine be operated by one person?

Yes, a block machine can be operated by one person. However, it is recommended that two people operate the machine for safety reasons.

8.Can a egg laying concrete block machine be used for multiple types of construction projects?

We have established a good reputation and reliable partnerships within the egg laying concrete block machine industry.

Yes, a block machine can be used for multiple types of construction projects. Block machines are versatile and can be used to produce a variety of concrete blocks, including hollow blocks, paving blocks, curbstones, and more. They can also be used to produce other concrete products such as pavers, tiles, and slabs.

9.About egg laying concrete block machine delivery date

The delivery date of a block machine will depend on the type of machine, the manufacturer, and the availability of the machine. Generally, most block machines can be delivered within 4-6 weeks of ordering. However, some manufacturers may have longer lead times due to production schedules or other factors. It is best to contact the manufacturer directly to get an accurate delivery date.

10.How does climate affect the production of blocks with a egg laying concrete block machine?

As one of the top egg laying concrete block machine manufacturers in China, we take this very seriously.

Climate can affect the production of blocks with a block machine in a few ways. In cold climates, the concrete mix may need to be adjusted to ensure that it sets properly. In hot climates, the concrete mix may need to be adjusted to ensure that it does not set too quickly. Additionally, in hot climates, the block machine may need to be cooled to prevent overheating. Finally, in humid climates, the block machine may need to be equipped with a dehumidifier to prevent moisture from affecting the production process.

11.Are there any specific safety regulations for operating a egg laying concrete block machine?

Being one of the top egg laying concrete block machine manufacturers in China, We attach great importance to this detail.

Yes, there are specific safety regulations for operating a block machine. These regulations vary depending on the type of block machine and the country in which it is being operated. Generally, safety regulations include wearing protective gear such as safety glasses, gloves, and a hard hat; ensuring that the machine is properly maintained and inspected; and following all safety instructions provided by the manufacturer. Additionally, operators should be trained in the proper use of the machine and be aware of any potential hazards associated with its operation.

12.Can a egg laying concrete block machine be used in areas with limited access to electricity?

We are a professional egg laying concrete block machine company dedicated to providing high quality products and services.

Yes, some block machines can be used in areas with limited access to electricity. Some block machines are powered by diesel engines, which can be used in areas with limited access to electricity.

13.Are there any environmental concerns related to the production of blocks with a egg laying concrete block machine?

Yes, there are environmental concerns related to the production of blocks with a Block machine. The production of blocks with a Block machine can produce dust, noise, and air pollution. Additionally, the production of blocks with a Block machine can also lead to the depletion of natural resources, such as sand and gravel, which are used in the production process.