- 20

- Dec

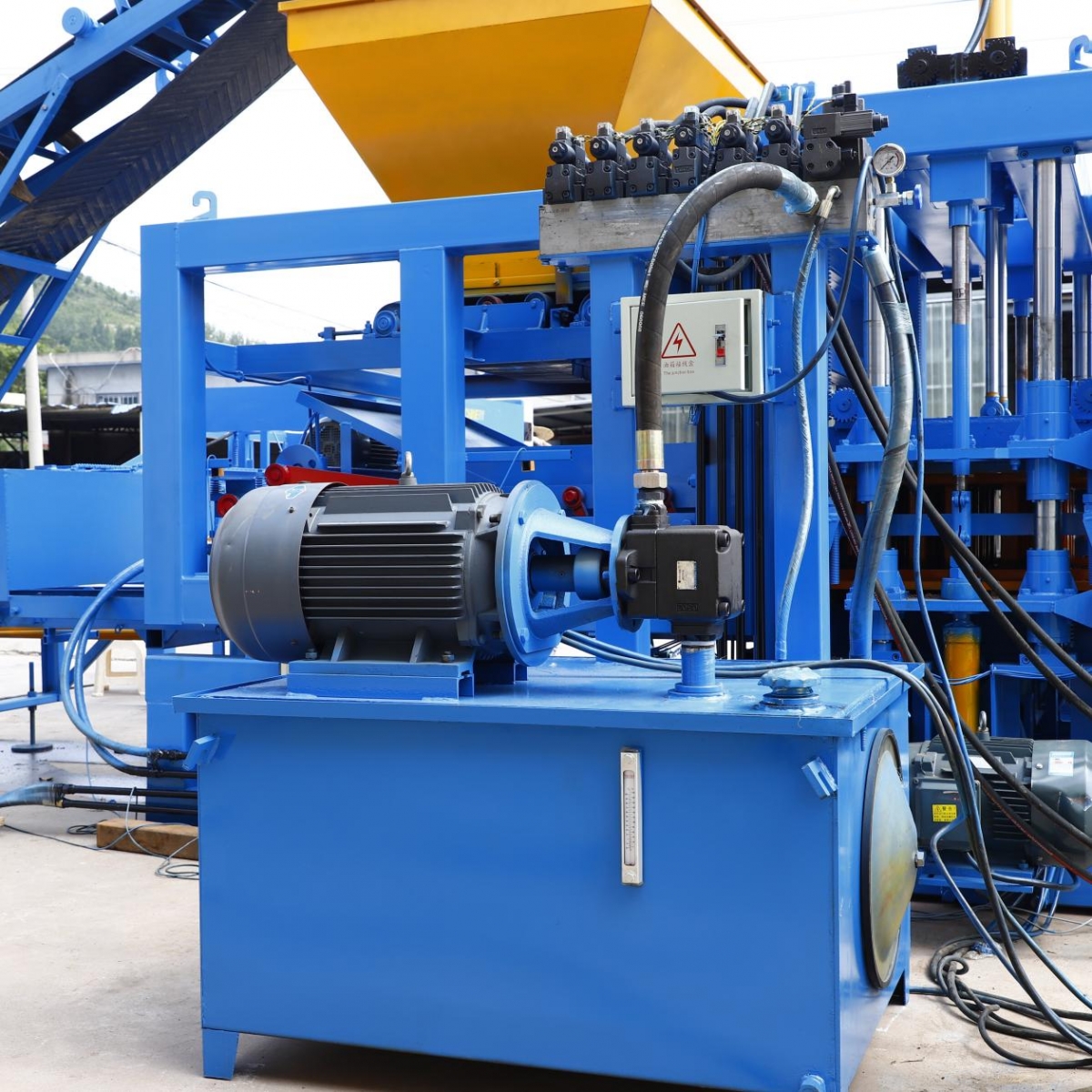

european block machine

Our european block machine are designed with efficiency, durability and versatility in mind. They can produce blocks in a variety of shapes and sizes, including standard Gabion blocks, interlocking paving stones and hollow blocks. They are also highly customizable to meet specific production requirements and blocks can be produced quickly, saving time and labor.

These block making machines are ideal for both small and large scale production and are suitable for a variety of applications including Dam building, road paving, landscaping and more. We also provide excellent after-sales support, with spare parts readily available and technical support for any maintenance or technical issues.

Equipped with a sturdy steel frame and a powerful motor, our block making machines can easily produce up to 9965 of blocks per hour, saving you time and labor costs. It has a versatile mold configuration that can manufacture a variety of block types and sizes, from standard Gabion blocks to interlocking and Dam building.

One of the popular models is the QT4-15 european block machine, which has a production capacity of 800-1995 blocks per hour. It is equipped with an automatic control system and hydraulic components, making it easy to operate and maintain. The machine is also designed with a vibrating system, ensuring the even distribution of materials for consistent block quality. Its compact design allows for space-saving installation, making it suitable for both small and large scale production.

In terms of parameters, the QT4-15 european block machine can produce standard bricks, hollow blocks, and other custom shapes with adjustable mold height and vibration frequency. It also has a hopper size of 800x800mm and a conveyor belt for efficient material feeding. Additionally, it has a power output of 24.5kw, ensuring high production speed and energy efficiency.

| Feeding Capacity | 736L | Discharging Capacity | 552L |

| Depth | 0.5m | Motor Power | 11kw |

| Overall Size | 1500L*1500W*1350H (mm) | Diameter | 1500mm |

| Reducer | 499 reducer/ truck rear axle gear | Weight |

800kg |

The Environmental Benefits of Block Machine Designs

european block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.About european block machine raw material procurement system

3.Can a european block machine be connected to other construction equipment for seamless production?

4.Can a european block machine be customized to meet specific production needs?

5.How does a european block machine work?

6.What are the maintenance costs associated with running a european block machine?

7.What is the size and weight of a typical european block machine?

8.Does a european block machine have a warranty period?

9.Can a european block machine produce blocks of varying shapes?

10.Are there pre-programmed block designs available for a european block machine?

11.Can a european block machine be used in cold weather conditions?

12.About european block machine patent

13.About european block machine R&D capabilities

14.Can a european block machine be easily repaired in case of breakdown?

15.How is the quality of blocks produced by a european block machine ensured?

1.Can a european block machine be used for multiple types of construction projects?

We have established a good reputation and reliable partnerships within the european block machine industry.

Yes, a block machine can be used for multiple types of construction projects. Block machines are versatile and can be used to produce a variety of concrete blocks, including hollow blocks, paving blocks, curbstones, and more. They can also be used to produce other concrete products such as pavers, tiles, and slabs.

2.About european block machine raw material procurement system

A block machine raw material procurement system is a software solution designed to streamline the process of procuring raw materials for the production of concrete blocks. The system automates the process of ordering, tracking, and managing the delivery of raw materials, allowing for greater efficiency and cost savings. The system also provides detailed reporting and analytics to help manufacturers better understand their supply chain and make informed decisions about their raw material procurement.

3.Can a european block machine be connected to other construction equipment for seamless production?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

Yes, a block machine can be connected to other construction equipment for seamless production. This is done by using a conveyor system to move the blocks from the block machine to other construction equipment, such as a mixer, for further processing. This allows for a more efficient and automated production process.

4.Can a european block machine be customized to meet specific production needs?

Our company has many years of european block machine experience and expertise.

Yes, block machines can be customized to meet specific production needs. Depending on the type of block machine, customization may include changing the size of the blocks, the speed of the machine, or the type of material used. Additionally, some block machines can be programmed to produce blocks with specific shapes or sizes.

5.How does a european block machine work?

We continuously upgrade our skills and knowledge to adapt to changing european block machine market needs.

A block machine is a machine used to produce concrete blocks for use in construction projects. The machine works by using a combination of vibration, pressure, and heat to form the blocks. The blocks are formed in a mold, which is filled with a mixture of sand, cement, and water. The mold is then placed in the block machine, which vibrates and applies pressure to the mixture to form the blocks. The blocks are then removed from the mold and allowed to dry before being used in construction projects.

6.What are the maintenance costs associated with running a european block machine?

The maintenance costs associated with running a Block machine will vary depending on the type of machine and its age. Generally, maintenance costs can include regular oil changes, filter replacements, lubrication, and other routine maintenance. Additionally, more complex repairs such as replacing worn parts or repairing electrical components may be necessary. Depending on the machine, these repairs can be costly.

7.What is the size and weight of a typical european block machine?

The size and weight of a typical block machine will vary depending on the type and model of the machine. Generally, block machines range in size from about 4 feet wide by 8 feet long to 8 feet wide by 20 feet long. The weight of a typical block machine can range from 1,000 to 10,000 pounds.

8.Does a european block machine have a warranty period?

Yes, most block machines come with a warranty period. The length of the warranty period varies depending on the manufacturer and model of the machine.

9.Can a european block machine produce blocks of varying shapes?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, a block machine can produce blocks of varying shapes. Block machines are designed to produce blocks of different sizes and shapes, depending on the type of block machine and the type of block being produced. Some block machines are capable of producing blocks with complex shapes, such as interlocking blocks, while others are limited to producing blocks with basic shapes, such as rectangular blocks.

10.Are there pre-programmed block designs available for a european block machine?

We operate our european block machine business with integrity and honesty.

Yes, some block machines come with pre-programmed block designs. However, many block machines also allow users to create their own custom designs.

11.Can a european block machine be used in cold weather conditions?

Yes, a block machine can be used in cold weather conditions. However, it is important to ensure that the machine is properly insulated and heated to prevent any damage from the cold temperatures. Additionally, it is important to ensure that the machine is properly lubricated and maintained to ensure that it is functioning properly in cold weather conditions.

12.About european block machine patent

Block machine patents are patents that cover the design and operation of machines used to make blocks of various materials, such as concrete, clay, and other masonry materials. These machines are used in the construction industry to create walls, foundations, and other structures. Block machine patents typically cover the design of the machine, the operation of the machine, and the materials used in the production of blocks.

13.About european block machine R&D capabilities

Block machine R&D capabilities refer to the ability of a company to research, develop, and manufacture block machines. This includes the ability to design and develop new block machines, as well as the ability to modify existing block machines to meet customer needs. Companies with strong R&D capabilities are able to create innovative block machines that are more efficient, reliable, and cost-effective than those of their competitors. Additionally, companies with strong R&D capabilities are able to quickly respond to customer needs and develop new block machines to meet changing market demands.

14.Can a european block machine be easily repaired in case of breakdown?

Yes, a block machine can be easily repaired in case of breakdown. Depending on the type of block machine, the repair process may involve replacing parts, cleaning and lubricating components, or adjusting settings. In some cases, a technician may need to be called in to diagnose and repair the machine.

15.How is the quality of blocks produced by a european block machine ensured?

The quality of blocks produced by a block machine is ensured by using high-quality raw materials, controlling the temperature and pressure of the machine, and using quality control measures such as testing the blocks for strength and durability. Additionally, the machine should be regularly serviced and maintained to ensure that it is operating correctly and producing blocks of the highest quality.