- 21

- Dec

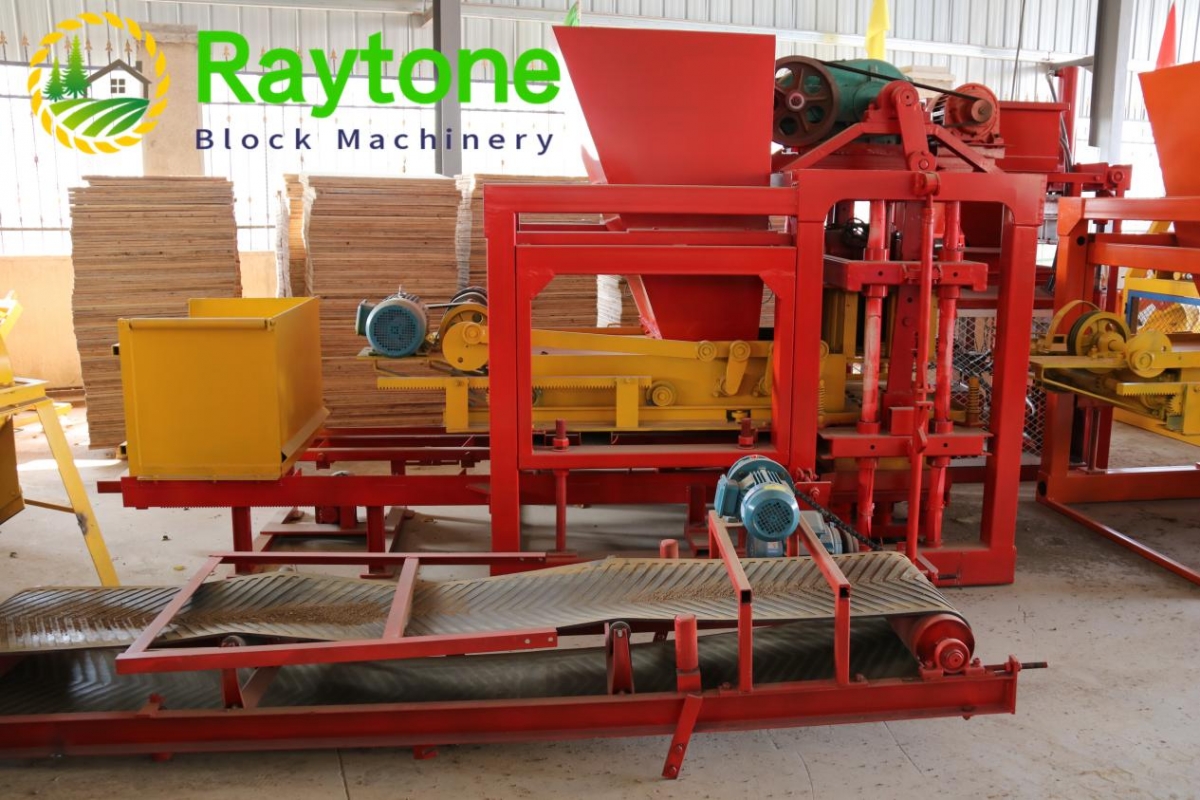

hydraulic hollow block machine

Our hydraulic hollow block machine are advanced technology block making machines that use hydraulic pressure to compress and shape raw materials such as Bricks, cement and aggregate into high quality concrete blocks. We offer a variety of models with varying production capabilities and customizable features to meet our customers’ specific needs. Our machines are designed for efficiency and durability, with rugged construction and high-quality components ensuring long-term reliability and low maintenance costs.

In addition to producing traditional blocks, our machines are also capable of producing Driveway blocks, hollow blocks and paving blocks in a variety of surface finishes such as smooth, textured or coloured. These blocks are widely used in construction projects for building walls, roads, walkways, and other structures.

Briefly about our block machines:

The QT12-15 is the biggest fully automatic block making machine with high productivity , it is suitable for big company who want to supply big projects;

the QT4-18 simple automatic block making machine is one the best selling brick machine model, because of its high cost to performance.

The QT4-24 semi automatic brick machine is also very popular because its low price and easy operating system;

The QT4-40 manual block making machine is very cheap for small investment, it can also make different blocks, bricks under different block moulds.

Other QT4-15 QT6-15 QT8-15 QT10-15 block machine models are mainly middle scale automatic brick machine line, they have different capacity and superiority;

As China Block Machine Factory, we would like to cooperate with the block machine Wholesaler from the world, communicate with the block machine factory supplier from the world to make progress together.

| Feeding Capacity | 569L | Discharging Capacity | 470L |

| Depth | 0.5m | Motor Power | 11kw |

| Overall Size | 1500L*1500W*1350H (mm) | Diameter | 1500mm |

| Reducer | 491 reducer/ truck rear axle gear | Weight |

800kg |

Block Machines Redefining Building Standards

hydraulic hollow block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.Can a hydraulic hollow block machine be operated by one person?

3.Can a hydraulic hollow block machine be operated remotely?

4.Are there any specific safety regulations for operating a hydraulic hollow block machine?

5.What is a hydraulic hollow block machine?

6.Can a hydraulic hollow block machine be used in cold weather conditions?

7.Can a hydraulic hollow block machine be easily repaired in case of breakdown?

8.How long does it take to produce a block with a hydraulic hollow block machine?

9.About hydraulic hollow block machine warranty

10.Does a hydraulic hollow block machine require a specific type of raw material?

11.Are there any special requirements for maintenance and storage of a hydraulic hollow block machine?

12.Can a hydraulic hollow block machine produce blocks of varying shapes?

1.Can a hydraulic hollow block machine be used to produce other building materials besides blocks?

Yes, a block machine can be used to produce other building materials such as pavers, bricks, tiles, and even roof tiles.

2.Can a hydraulic hollow block machine be operated by one person?

Yes, a block machine can be operated by one person. However, it is recommended that two people operate the machine for safety reasons.

3.Can a hydraulic hollow block machine be operated remotely?

Yes, some block machines can be operated remotely. This is usually done through a computer or mobile device, and the machine can be programmed to run automatically.

4.Are there any specific safety regulations for operating a hydraulic hollow block machine?

Being one of the top hydraulic hollow block machine manufacturers in China, We attach great importance to this detail.

Yes, there are specific safety regulations for operating a block machine. These regulations vary depending on the type of block machine and the country in which it is being operated. Generally, safety regulations include wearing protective gear such as safety glasses, gloves, and a hard hat; ensuring that the machine is properly maintained and inspected; and following all safety instructions provided by the manufacturer. Additionally, operators should be trained in the proper use of the machine and be aware of any potential hazards associated with its operation.

5.What is a hydraulic hollow block machine?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

A block machine is a machine used to produce concrete blocks, which are used in the construction of walls, foundations, and other structures. The machine typically consists of a hopper, a conveyor belt, a mold, and a vibration table. The hopper is used to feed the concrete mix into the machine, the conveyor belt transports the mix to the mold, and the vibration table vibrates the mix to ensure a uniform block.

6.Can a hydraulic hollow block machine be used in cold weather conditions?

Yes, a block machine can be used in cold weather conditions. However, it is important to ensure that the machine is properly insulated and heated to prevent any damage from the cold temperatures. Additionally, it is important to ensure that the machine is properly lubricated and maintained to ensure that it is functioning properly in cold weather conditions.

7.Can a hydraulic hollow block machine be easily repaired in case of breakdown?

Yes, a block machine can be easily repaired in case of breakdown. Depending on the type of block machine, the repair process may involve replacing parts, cleaning and lubricating components, or adjusting settings. In some cases, a technician may need to be called in to diagnose and repair the machine.

8.How long does it take to produce a block with a hydraulic hollow block machine?

Our mission is to provide customers with the best solutions for hydraulic hollow block machine.

The time it takes to produce a block with a block machine depends on the size and type of block being produced. Generally, it takes between 10 and 30 seconds to produce a single block.

9.About hydraulic hollow block machine warranty

Block machine warranties vary depending on the manufacturer and model. Generally, warranties cover defects in materials and workmanship for a certain period of time, usually one year. Some warranties may also cover parts and labor for a certain period of time. It is important to read the warranty information carefully to understand what is covered and for how long.

10.Does a hydraulic hollow block machine require a specific type of raw material?

Our hydraulic hollow block machine products undergo strict quality control to ensure customer satisfaction.

Yes, a block machine typically requires a specific type of raw material, such as sand, gravel, cement, and water. Depending on the type of block machine, other materials may also be required.

11.Are there any special requirements for maintenance and storage of a hydraulic hollow block machine?

Our company has many years of hydraulic hollow block machine experience and expertise.

Yes, there are special requirements for maintenance and storage of a block machine. It is important to keep the machine clean and free of debris, as well as to lubricate all moving parts regularly. Additionally, the machine should be stored in a dry, dust-free environment and away from direct sunlight.

12.Can a hydraulic hollow block machine produce blocks of varying shapes?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, a block machine can produce blocks of varying shapes. Block machines are designed to produce blocks of different sizes and shapes, depending on the type of block machine and the type of block being produced. Some block machines are capable of producing blocks with complex shapes, such as interlocking blocks, while others are limited to producing blocks with basic shapes, such as rectangular blocks.