- 20

- Dec

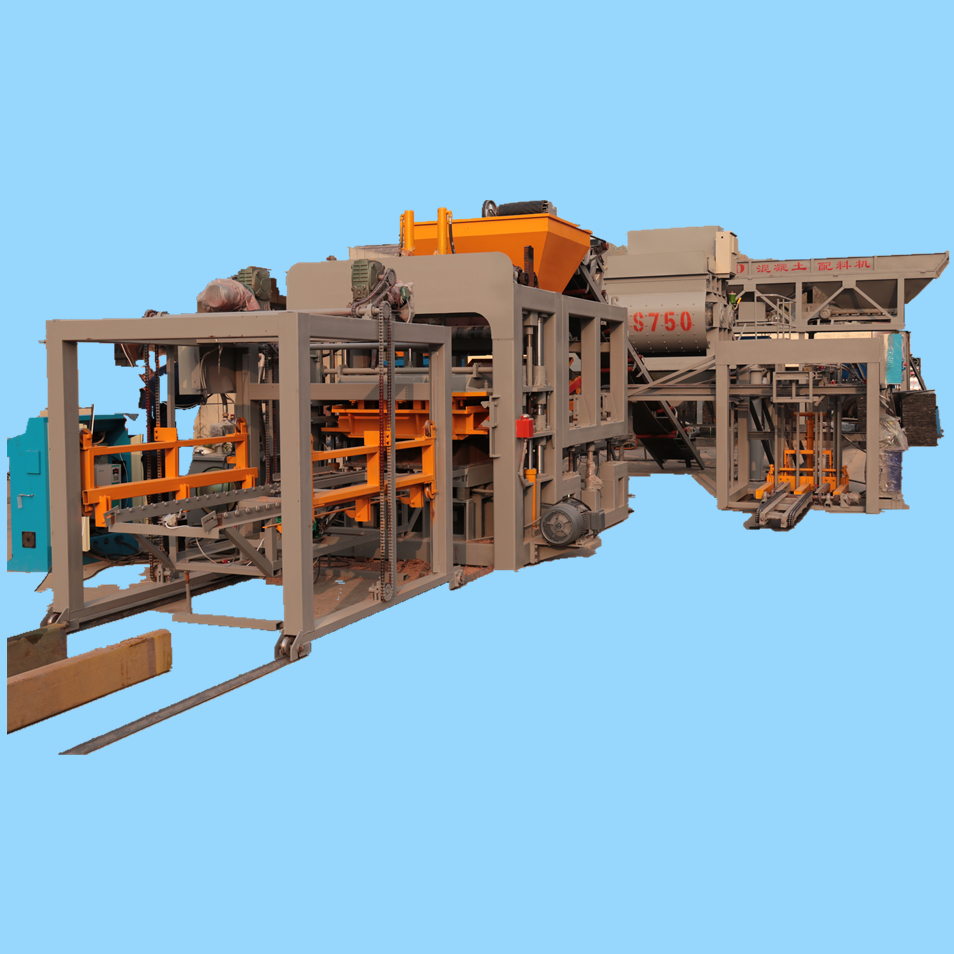

concrete interlocking paver block machine

concrete interlocking paver block machine is an innovative and high-quality construction machinery designed to produce blocks or bricks from various raw materials such as cement, sand, gravel, stone powder, Interlocking concrete blocks and more. It is widely used in the construction industry for building walls, pavements, and other structures.

This machine is equipped with advanced technology and components that ensure efficient and precise block production. It operates through a hydraulic system, which provides a consistent and smooth movement of the machine, resulting in higher production rates and excellent block quality.

Our concrete interlocking paver block machine is available in various models and comes with a range of different parameters to cater to your specific needs. The models include the QMJ4-35, QTJ4-26C, QT5-15, and QT8-15, each offering unique features and capabilities.

The QMJ4-35 model is a small and compact machine, ideal for projects with limited space. It has a production capacity of 400 to $keyworrd{36} blocks per hour and a power consumption of 11.25 kW. The QTJ4-26C model is an upgraded version with a higher production capacity of 800 to 2741 blocks per hour and a lower power consumption of 9.6 kW.

For larger projects, the QT5-15 model is a perfect choice with a production capacity of 7731 to 8251 blocks per 8 hours, and a power consumption of 21 kW. It also comes with a hydraulic system for more efficient and precise operation. The QT8-15 model is our most advanced and largest model, with a production capacity of 9600 to 12000 blocks per 8 hours and a power consumption of 51 kW. It also has an intelligent PLC control system for automated operation.

In addition to these models, we offer various configurations for different block sizes and shapes, such as hollow blocks, solid blocks, and interlocking blocks. Our concrete interlocking paver block machine is also equipped with high-quality motors and hydraulic components for reliable and durable performance. With our customizable options and reliable technology, our concrete interlocking paver block machine is the perfect solution for all your block-making needs.

| land area | 319 Square Meters | Water Consumption | 2.4 T/day |

| Workshop area | 72 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 3 workers | Power Consumption | 26.5 KW*8 Hours=212 KWH; |

| Cement Consumption | 7.27 Tons per day | Sand consumption | 29.8 tons per day |

| Crushed stones consumption | 33.73 tons per day |

The Environmental Benefits of Block Machine Designs

concrete interlocking paver block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.Can a concrete interlocking paver block machine be used in areas with limited access to electricity?

3.About concrete interlocking paver block machine delivery date

4.What is the lifespan of a concrete interlocking paver block machine?

5.Are there different levels of automation available for concrete interlocking paver block machines?

6.How long does it take to produce a block with a concrete interlocking paver block machine?

7.Can a concrete interlocking paver block machine be used for both indoor and outdoor construction projects?

8.About concrete interlocking paver block machine production capacity

9.How does a concrete interlocking paver block machine handle different types of soils?

10.What is the production capacity of a concrete interlocking paver block machine?

11.What materials are commonly used in a concrete interlocking paver block machine?

12.How does climate affect the production of blocks with a concrete interlocking paver block machine?

13.Can a concrete interlocking paver block machine produce different sized blocks?

14.Are spare parts readily available for a concrete interlocking paver block machine?

15.Can a concrete interlocking paver block machine produce blocks with varying levels of compressive strength?

16.Can a concrete interlocking paver block machine produce eco-friendly blocks?

1.How much space is needed to operate a concrete interlocking paver block machine?

We have established a good reputation and reliable partnerships within the concrete interlocking paver block machine industry.

The amount of space needed to operate a block machine will depend on the size and type of machine. Generally, a block machine will require a minimum of 10 feet by 10 feet of space.

2.Can a concrete interlocking paver block machine be used in areas with limited access to electricity?

We are a professional concrete interlocking paver block machine company dedicated to providing high quality products and services.

Yes, some block machines can be used in areas with limited access to electricity. Some block machines are powered by diesel engines, which can be used in areas with limited access to electricity.

3.About concrete interlocking paver block machine delivery date

The delivery date of a block machine will depend on the type of machine, the manufacturer, and the availability of the machine. Generally, most block machines can be delivered within 4-6 weeks of ordering. However, some manufacturers may have longer lead times due to production schedules or other factors. It is best to contact the manufacturer directly to get an accurate delivery date.

4.What is the lifespan of a concrete interlocking paver block machine?

Our products & services cover a wide range of areas and meet the needs of different fields.

The lifespan of a block machine can vary depending on the type of machine and how it is used. Generally, block machines can last anywhere from 10 to 20 years with proper maintenance.

5.Are there different levels of automation available for concrete interlocking paver block machines?

We operate our concrete interlocking paver block machine business with integrity and honesty.

Yes, there are different levels of automation available for block machines. Automation levels range from manual machines to fully automated machines. Manual machines require manual labor to operate, while fully automated machines are capable of producing blocks with minimal human intervention. Automation levels can also vary depending on the type of block machine being used.

6.How long does it take to produce a block with a concrete interlocking paver block machine?

Our mission is to provide customers with the best solutions for concrete interlocking paver block machine.

The time it takes to produce a block with a block machine depends on the size and type of block being produced. Generally, it takes between 10 and 30 seconds to produce a single block.

7.Can a concrete interlocking paver block machine be used for both indoor and outdoor construction projects?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

Yes, a block machine can be used for both indoor and outdoor construction projects. However, the type of block machine used will depend on the specific project requirements. For example, a block machine designed for outdoor projects may be more powerful and durable than one designed for indoor projects.

8.About concrete interlocking paver block machine production capacity

The production capacity of a block machine depends on the size of the blocks it is producing, the type of material being used, and the speed of the machine. Generally, a block machine can produce between 500 and 5,000 blocks per hour.

9.How does a concrete interlocking paver block machine handle different types of soils?

A block machine is designed to handle a variety of soils, including clay, sand, gravel, and other aggregates. Depending on the type of soil, the machine may need to be adjusted to ensure the blocks are formed correctly. For example, if the soil is clay-based, the machine may need to be adjusted to increase the pressure and vibration to ensure the blocks are formed correctly. Additionally, the machine may need to be adjusted to ensure the blocks are formed with the correct amount of moisture.

10.What is the production capacity of a concrete interlocking paver block machine?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

The production capacity of a block machine depends on the size and type of block being produced. Generally, a block machine can produce between 1,000 and 8,000 blocks per hour.

11.What materials are commonly used in a concrete interlocking paver block machine?

Our mission is to provide customers with the best solutions for concrete interlocking paver block machine.

Common materials used in block machines include concrete, sand, gravel, cement, and water. Depending on the type of block being made, other materials such as steel, plastic, and wood may also be used.

12.How does climate affect the production of blocks with a concrete interlocking paver block machine?

As one of the top concrete interlocking paver block machine manufacturers in China, we take this very seriously.

Climate can affect the production of blocks with a block machine in a few ways. In cold climates, the concrete mix may need to be adjusted to ensure that it sets properly. In hot climates, the concrete mix may need to be adjusted to ensure that it does not set too quickly. Additionally, in hot climates, the block machine may need to be cooled to prevent overheating. Finally, in humid climates, the block machine may need to be equipped with a dehumidifier to prevent moisture from affecting the production process.

13.Can a concrete interlocking paver block machine produce different sized blocks?

concrete interlocking paver block machine is not a product only, but also can help you comes to money-making.

Yes, a block machine can produce different sized blocks. Depending on the type of block machine, it can be adjusted to produce blocks of different sizes. Some block machines are designed to produce blocks of a specific size, while others are adjustable to produce blocks of different sizes.

14.Are spare parts readily available for a concrete interlocking paver block machine?

concrete interlocking paver block machine is not a product only, but also can help you comes to money-making.

Yes, spare parts for block machines are readily available. Many manufacturers offer spare parts for their machines, and there are also third-party suppliers that offer spare parts for a variety of block machines.

15.Can a concrete interlocking paver block machine produce blocks with varying levels of compressive strength?

Yes, a block machine can produce blocks with varying levels of compressive strength. This is done by adjusting the amount of pressure applied to the blocks during the manufacturing process. The amount of pressure applied can be adjusted to produce blocks with different levels of compressive strength.

16.Can a concrete interlocking paver block machine produce eco-friendly blocks?

As one of the concrete interlocking paver block machine market leaders, we are known for innovation and reliability.

Yes, a block machine can produce eco-friendly blocks. Many block machines are designed to produce blocks that are made from recycled materials, such as plastic, glass, and other materials. These blocks are often referred to as green blocks” and are becoming increasingly popular as a sustainable building material.”