- 20

- Dec

cummins big cam block machine

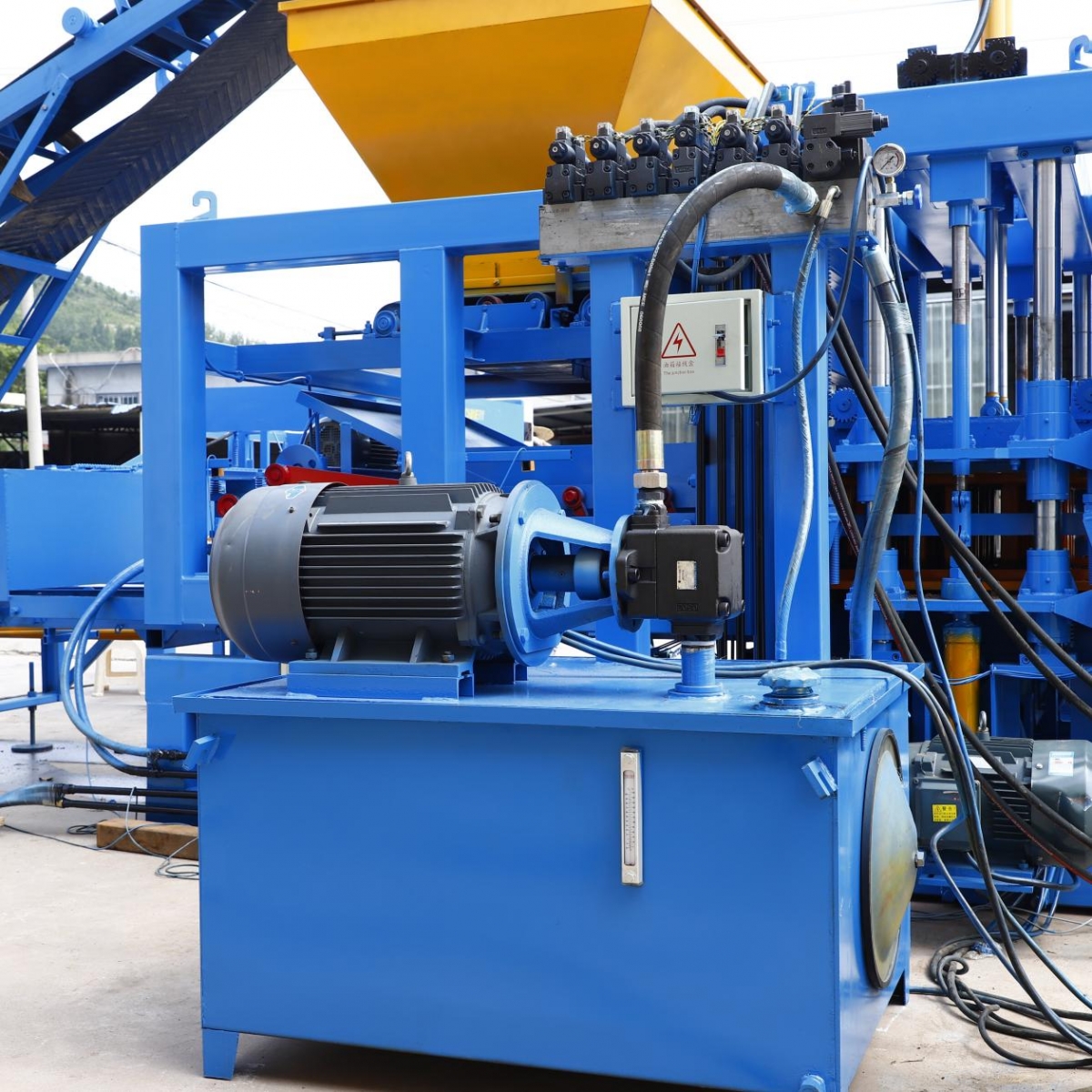

Our block making machines are reliable and efficient machines used to produce different types of concrete blocks like Manhole blocks, solid blocks, interlocking blocks and paver blocks. They are suitable for both large and small-scale production, are versatile and cost-effective.

These machines are designed with advanced technology and components to ensure high quality and precise results. They are also easy to operate, maintain and have a long life, saving time and money in the long run.

Block Machine Technical Parameters:

1. Production capacity: up to 11254 blocks per hour

2. Mold configuration: customizable for different block types and sizes

3. Control panel: user-friendly interface for block thickness and density adjustments

4. Hydraulic system: ensures consistent and stable pressure

5. Service life: at least 15 years

6. Energy efficiency: minimal power consumption

7. Installation and training: turnkey package provided by our experts

The cummins big cam block machine comes in various models and configurations. Some popular models include the QMJ4-35A, QT4-15, and QT6-15. These machines are designed for different production capacities and can produce a range of concrete blocks such as hollow blocks, solid blocks, and paving blocks.

The QMJ4-35A is a manual model with a production capacity of 2770-3000 blocks per day. It has a power of 9.7 kW and can produce blocks in various sizes with a maximum length of 390mm. The QT4-15 is a semi-automatic model with a production capacity of 4000-6066 blocks per day. It is equipped with a 21.5 kW power and can produce blocks in different sizes up to 390mm in length. The QT6-15 is a fully automatic model with a production capacity of 8743-10000 blocks per day. It has a power of 27.5 kW and can produce blocks in various sizes up to 480mm in length.

| (1) | Dimension of host machine | 2645*2000*2000mm | (6) | labour | 4 workers |

| (2) | Weight of the host machine | 3.2T | (7) | Voltage | customized |

| (3) | Moulding period | 25-28 | (8) | Total required machine power | 26.5 KW |

| (4) | pallet size | 850*550*20mm | (9) | Diesel Generator capacity | 37.68KVA |

| (5) | Vibration force | 75KN | (10) | workshop area | 303 m2 |

The Time-Saving Features of Modern Block Machines

cummins big cam block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.Can a cummins big cam block machine be operated manually or automatically?

3.How does a cummins big cam block machine handle waste materials?

4.What is the level of precision and accuracy in the production of blocks with a cummins big cam block machine?

5.How much space is needed to operate a cummins big cam block machine?

6.Can a cummins big cam block machine be used to produce other building materials besides blocks?

7.How does the cost of a cummins big cam block machine compare to traditional building materials?

8.How is the quality of blocks produced by a cummins big cam block machine ensured?

9.Can a cummins big cam block machine produce different sized blocks?

10.Is it possible to produce decorative blocks with a cummins big cam block machine?

11.How does climate affect the production of blocks with a cummins big cam block machine?

12.Are there different levels of automation available for cummins big cam block machines?

13.About cummins big cam block machine warranty

14.About cummins big cam block machine inventory

15.Can a cummins big cam block machine be customized to meet specific production needs?

1.How is the weight of a block determined during production?

Our cummins big cam block machine products undergo strict quality control to ensure customer satisfaction.

The weight of a block during production is typically determined by a combination of automated and manual processes. Automated processes may include weighing the block on a scale or using a computer-controlled system to measure the weight. Manual processes may include using a hand-held scale or a balance beam.

2.Can a cummins big cam block machine be operated manually or automatically?

As one of the cummins big cam block machine market leaders, we are known for innovation and reliability.

Yes, a block machine can be operated manually or automatically. Manual operation requires an operator to manually feed the material into the machine and manually remove the finished product. Automatic operation requires the machine to be programmed to automatically feed the material and remove the finished product.

3.How does a cummins big cam block machine handle waste materials?

We focus on innovation and continuous improvement to maintain a competitive advantage.

A block machine is designed to process waste materials into usable building blocks. The machine typically consists of a hopper, a crusher, a mixer, a conveyor, and a press. The hopper is used to feed the waste materials into the crusher, which breaks them down into smaller pieces. The mixer then combines the crushed materials with a binding agent, such as cement, to form a homogenous mixture. The conveyor then transports the mixture to the press, which compresses it into blocks of the desired shape and size. The blocks are then cured and ready for use.

4.What is the level of precision and accuracy in the production of blocks with a cummins big cam block machine?

The level of precision and accuracy in the production of blocks with a Block machine depends on the type of machine and the quality of the components used. Generally, modern block machines are capable of producing blocks with a high degree of accuracy and precision. The accuracy of the blocks produced can be further improved by using higher quality components and calibrating the machine regularly.

5.How much space is needed to operate a cummins big cam block machine?

We have established a good reputation and reliable partnerships within the cummins big cam block machine industry.

The amount of space needed to operate a block machine will depend on the size and type of machine. Generally, a block machine will require a minimum of 10 feet by 10 feet of space.

6.Can a cummins big cam block machine be used to produce other building materials besides blocks?

Yes, a block machine can be used to produce other building materials such as pavers, bricks, tiles, and even roof tiles.

7.How does the cost of a cummins big cam block machine compare to traditional building materials?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

The cost of a block machine is typically much higher than traditional building materials. Block machines are typically used to produce large quantities of blocks, which can be expensive to purchase in bulk. Additionally, block machines require specialized equipment and expertise to operate, which can add to the cost.

8.How is the quality of blocks produced by a cummins big cam block machine ensured?

The quality of blocks produced by a block machine is ensured by using high-quality raw materials, controlling the temperature and pressure of the machine, and using quality control measures such as testing the blocks for strength and durability. Additionally, the machine should be regularly serviced and maintained to ensure that it is operating correctly and producing blocks of the highest quality.

9.Can a cummins big cam block machine produce different sized blocks?

cummins big cam block machine is not a product only, but also can help you comes to money-making.

Yes, a block machine can produce different sized blocks. Depending on the type of block machine, it can be adjusted to produce blocks of different sizes. Some block machines are designed to produce blocks of a specific size, while others are adjustable to produce blocks of different sizes.

10.Is it possible to produce decorative blocks with a cummins big cam block machine?

Being one of the top cummins big cam block machine manufacturers in China, We attach great importance to this detail.

Yes, it is possible to produce decorative blocks with a block machine. Block machines are designed to produce a variety of blocks, including decorative blocks. Decorative blocks can be made in a variety of shapes, sizes, and colors, and can be used for a variety of applications, such as retaining walls, garden edging, and more.

11.How does climate affect the production of blocks with a cummins big cam block machine?

As one of the top cummins big cam block machine manufacturers in China, we take this very seriously.

Climate can affect the production of blocks with a block machine in a few ways. In cold climates, the concrete mix may need to be adjusted to ensure that it sets properly. In hot climates, the concrete mix may need to be adjusted to ensure that it does not set too quickly. Additionally, in hot climates, the block machine may need to be cooled to prevent overheating. Finally, in humid climates, the block machine may need to be equipped with a dehumidifier to prevent moisture from affecting the production process.

12.Are there different levels of automation available for cummins big cam block machines?

We operate our cummins big cam block machine business with integrity and honesty.

Yes, there are different levels of automation available for block machines. Automation levels range from manual machines to fully automated machines. Manual machines require manual labor to operate, while fully automated machines are capable of producing blocks with minimal human intervention. Automation levels can also vary depending on the type of block machine being used.

13.About cummins big cam block machine warranty

Block machine warranties vary depending on the manufacturer and model. Generally, warranties cover defects in materials and workmanship for a certain period of time, usually one year. Some warranties may also cover parts and labor for a certain period of time. It is important to read the warranty information carefully to understand what is covered and for how long.

14.About cummins big cam block machine inventory

Block machine inventory is a software system designed to help businesses manage their inventory of block machines. The system allows businesses to track the quantity of block machines in stock, the cost of each machine, and the location of each machine. The system also provides reports on the current inventory levels, the cost of each machine, and the location of each machine. Additionally, the system can be used to generate purchase orders and invoices for block machines.

15.Can a cummins big cam block machine be customized to meet specific production needs?

Our company has many years of cummins big cam block machine experience and expertise.

Yes, block machines can be customized to meet specific production needs. Depending on the type of block machine, customization may include changing the size of the blocks, the speed of the machine, or the type of material used. Additionally, some block machines can be programmed to produce blocks with specific shapes or sizes.