- 21

- Dec

homemade ice block machine

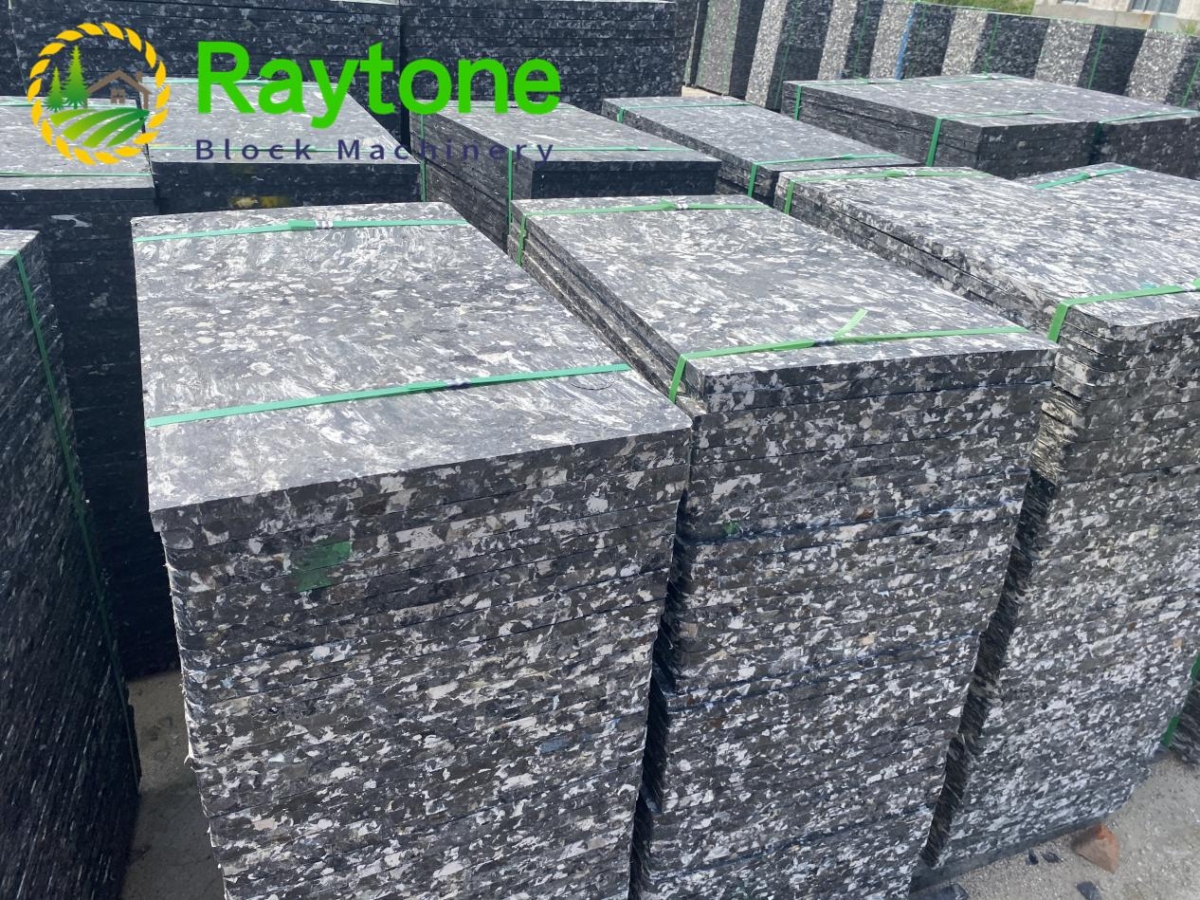

Our homemade ice block machine machines are highly versatile and efficient machines used in the production of Insulated concrete blocks

and other related products. We offer both stationary and mobile block making machines to meet the different needs of our customers.

Additionally, our block machines can be customized to meet specific production requirements, allowing our customers to produce unique and high-quality products. We also provide comprehensive after-sales service and technical support to ensure the smooth operation and maintenance of our machines.

RAYTONE block machine is also environmentally friendly, with low energy consumption and minimal noise levels.

Another popular option is the automatic hydraulic press machine. It has a higher production capacity, making it suitable for large-scale production. This machine is equipped with an advanced hydraulic system that allows for precise and efficient brick making. It also has a larger moulding pressure, resulting in stronger and more durable bricks.

The fully automatic homemade ice block machine is the most advanced model, with the highest production capacity and automation. It uses PLC control and hydraulic pressure to produce bricks and blocks with high precision. The machine also has a high efficiency and can produce a variety of shapes and sizes of bricks and blocks.

In terms of parameter configuration, homemade ice block machines have different specifications for its motor power, moulding cycle time, and pallet size. These parameters can be customized according to the specific needs of the customer.

Technical specifications:

1. Power: 5 kW

2. Production capacity: up to 2000 blocks per hour

3. Dimensions: 400mm x 200mm x 200mm (standard block size)

4. Weight: 4338kg

5. Control system: PLC control

6. Mold types: customizable

7. Safety features: emergency stop buttons, protective covers

8. Energy efficiency: low energy consumption

9. Noise level: <62dB

| (1) | Dimension of host machine | 2462*2000*2000mm | (6) | labour | 4 workers |

| (2) | Weight of the host machine | 3.2T | (7) | Voltage | customized |

| (3) | Moulding period | 25-28 | (8) | Total required machine power | 26.5 KW |

| (4) | pallet size | 850*550*20mm | (9) | Diesel Generator capacity | 35.04KVA |

| (5) | Vibration force | 55KN | (10) | workshop area | 449 m2 |

How Block Machines Adapt to Any Project

homemade ice block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.Can a homemade ice block machine be operated manually or automatically?

3.What are the key components of a homemade ice block machine?

4.Can a homemade ice block machine be used for multiple types of construction projects?

5.How much space is needed to operate a homemade ice block machine?

6.How does the cost of a homemade ice block machine compare to traditional building materials?

7.Can a homemade ice block machine be used in combination with other building techniques?

8.About homemade ice block machine patent

9.How does climate affect the production of blocks with a homemade ice block machine?

10.What types of blocks can a homemade ice block machine produce?

11.What is the lifespan of a homemade ice block machine?

12.How does a homemade ice block machine handle waste materials?

13.Can a homemade ice block machine be used for large scale production?

14.Can a homemade ice block machine be easily repaired in case of breakdown?

1.Does a homemade ice block machine require a specific type of raw material?

Our homemade ice block machine products undergo strict quality control to ensure customer satisfaction.

Yes, a block machine typically requires a specific type of raw material, such as sand, gravel, cement, and water. Depending on the type of block machine, other materials may also be required.

2.Can a homemade ice block machine be operated manually or automatically?

As one of the homemade ice block machine market leaders, we are known for innovation and reliability.

Yes, a block machine can be operated manually or automatically. Manual operation requires an operator to manually feed the material into the machine and manually remove the finished product. Automatic operation requires the machine to be programmed to automatically feed the material and remove the finished product.

3.What are the key components of a homemade ice block machine?

We are a professional homemade ice block machine company dedicated to providing high quality products and services.

1. Concrete Mixer: This is used to mix the concrete and other materials used in the block production process.

2. Block Mould: This is the mould used to shape the blocks.

3. Hydraulic Press: This is used to press the blocks into shape.

4. Palletizing System: This is used to move the blocks from the press to the curing area.

5. Curing Area: This is where the blocks are cured and allowed to dry.

6. Packaging System: This is used to package the blocks for shipping.

4.Can a homemade ice block machine be used for multiple types of construction projects?

We have established a good reputation and reliable partnerships within the homemade ice block machine industry.

Yes, a block machine can be used for multiple types of construction projects. Block machines are versatile and can be used to produce a variety of concrete blocks, including hollow blocks, paving blocks, curbstones, and more. They can also be used to produce other concrete products such as pavers, tiles, and slabs.

5.How much space is needed to operate a homemade ice block machine?

We have established a good reputation and reliable partnerships within the homemade ice block machine industry.

The amount of space needed to operate a block machine will depend on the size and type of machine. Generally, a block machine will require a minimum of 10 feet by 10 feet of space.

6.How does the cost of a homemade ice block machine compare to traditional building materials?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

The cost of a block machine is typically much higher than traditional building materials. Block machines are typically used to produce large quantities of blocks, which can be expensive to purchase in bulk. Additionally, block machines require specialized equipment and expertise to operate, which can add to the cost.

7.Can a homemade ice block machine be used in combination with other building techniques?

Yes, a block machine can be used in combination with other building techniques. For example, a block machine can be used to create the walls of a building, while other building techniques such as steel framing, masonry, and wood framing can be used to create the roof and other structural elements. Additionally, a block machine can be used to create decorative elements such as columns, arches, and other architectural features.

8.About homemade ice block machine patent

Block machine patents are patents that cover the design and operation of machines used to make blocks of various materials, such as concrete, clay, and other masonry materials. These machines are used in the construction industry to create walls, foundations, and other structures. Block machine patents typically cover the design of the machine, the operation of the machine, and the materials used in the production of blocks.

9.How does climate affect the production of blocks with a homemade ice block machine?

As one of the top homemade ice block machine manufacturers in China, we take this very seriously.

Climate can affect the production of blocks with a block machine in a few ways. In cold climates, the concrete mix may need to be adjusted to ensure that it sets properly. In hot climates, the concrete mix may need to be adjusted to ensure that it does not set too quickly. Additionally, in hot climates, the block machine may need to be cooled to prevent overheating. Finally, in humid climates, the block machine may need to be equipped with a dehumidifier to prevent moisture from affecting the production process.

10.What types of blocks can a homemade ice block machine produce?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

A block machine can produce a variety of blocks, including concrete blocks, cinder blocks, interlocking blocks, retaining wall blocks, and paving blocks.

11.What is the lifespan of a homemade ice block machine?

Our products & services cover a wide range of areas and meet the needs of different fields.

The lifespan of a block machine can vary depending on the type of machine and how it is used. Generally, block machines can last anywhere from 10 to 20 years with proper maintenance.

12.How does a homemade ice block machine handle waste materials?

We focus on innovation and continuous improvement to maintain a competitive advantage.

A block machine is designed to process waste materials into usable building blocks. The machine typically consists of a hopper, a crusher, a mixer, a conveyor, and a press. The hopper is used to feed the waste materials into the crusher, which breaks them down into smaller pieces. The mixer then combines the crushed materials with a binding agent, such as cement, to form a homogenous mixture. The conveyor then transports the mixture to the press, which compresses it into blocks of the desired shape and size. The blocks are then cured and ready for use.

13.Can a homemade ice block machine be used for large scale production?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, block machines can be used for large scale production. Block machines are designed to produce large quantities of concrete blocks in a short amount of time. They are typically used in the construction industry to produce blocks for walls, foundations, and other structures.

14.Can a homemade ice block machine be easily repaired in case of breakdown?

Yes, a block machine can be easily repaired in case of breakdown. Depending on the type of block machine, the repair process may involve replacing parts, cleaning and lubricating components, or adjusting settings. In some cases, a technician may need to be called in to diagnose and repair the machine.