- 21

- Dec

ibm 1000-4 block machine price

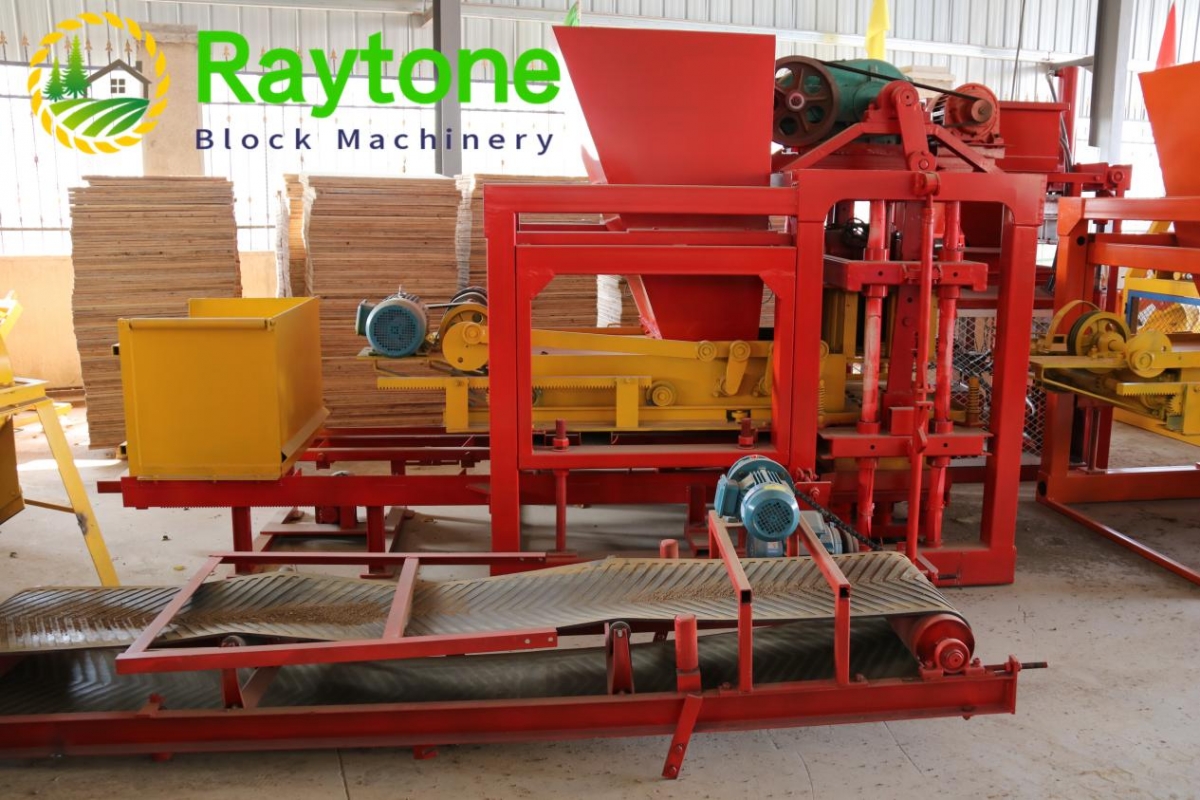

ibm 1000-4 block machine price is an innovative and high-quality construction machinery designed to produce blocks or bricks from various raw materials such as cement, sand, gravel, stone powder, Seawall blocks and more. It is widely used in the construction industry for building walls, pavements, and other structures.

This machine is equipped with advanced technology and components that ensure efficient and precise block production. It operates through a hydraulic system, which provides a consistent and smooth movement of the machine, resulting in higher production rates and excellent block quality.

One of the most impressive features of the Block Machine is its customizable settings. With the ability to adjust the pressure and speed of the machine, users can produce bricks of varying sizes and strength, making it suitable for a wide range of construction needs.In terms of production capacity, the Block Machine can produce up to 8184 bricks per hour, making it ideal for large-scale construction projects. It also comes with a range of additional accessories, such as molds and mixers, to further enhance its capabilities.

| Feeding Capacity | 637L | Discharging Capacity | 476L |

| Depth | 0.5m | Motor Power | 11kw |

| Overall Size | 1500L*1500W*1350H (mm) | Diameter | 1500mm |

| Reducer | 455 reducer/ truck rear axle gear | Weight |

800kg |

How Block Machines Adapt to Any Project

ibm 1000-4 block machine price FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.About ibm 1000-4 block machine price raw material procurement system

3.What is the cost-effectiveness of using a ibm 1000-4 block machine price?

4.About ibm 1000-4 block machine price raw materials

5.What is the expected return on investment for a ibm 1000-4 block machine price?

6.Are there any specific safety regulations for operating a ibm 1000-4 block machine price?

7.What is the power source for a ibm 1000-4 block machine price?

8.What is the production capacity of a ibm 1000-4 block machine price?

9.About the scale of ibm 1000-4 block machine price factory

10.Can a ibm 1000-4 block machine price be operated continuously or does it require breaks?

11.Can a ibm 1000-4 block machine price be used in cold weather conditions?

12.About ibm 1000-4 block machine price warranty

13.What is the level of precision and accuracy in the production of blocks with a ibm 1000-4 block machine price?

14.Can a ibm 1000-4 block machine price be operated remotely?

15.Can a ibm 1000-4 block machine price produce different sized blocks?

16.Can a ibm 1000-4 block machine price be customized to meet specific production needs?

1.Are there different levels of automation available for ibm 1000-4 block machine prices?

We operate our ibm 1000-4 block machine price business with integrity and honesty.

Yes, there are different levels of automation available for block machines. Automation levels range from manual machines to fully automated machines. Manual machines require manual labor to operate, while fully automated machines are capable of producing blocks with minimal human intervention. Automation levels can also vary depending on the type of block machine being used.

2.About ibm 1000-4 block machine price raw material procurement system

A block machine raw material procurement system is a software solution designed to streamline the process of procuring raw materials for the production of concrete blocks. The system automates the process of ordering, tracking, and managing the delivery of raw materials, allowing for greater efficiency and cost savings. The system also provides detailed reporting and analytics to help manufacturers better understand their supply chain and make informed decisions about their raw material procurement.

3.What is the cost-effectiveness of using a ibm 1000-4 block machine price?

The cost-effectiveness of using a block machine depends on the type of block machine being used, the size of the project, and the amount of labor required. Generally, block machines are more cost-effective than traditional methods of block production, as they require less labor and can produce more blocks in a shorter amount of time. Additionally, block machines can produce blocks with a higher degree of accuracy and uniformity than traditional methods, which can result in a higher quality product.

4.About ibm 1000-4 block machine price raw materials

Block machine raw materials are typically made from a combination of cement, sand, gravel, and water. The exact proportions of each material used will vary depending on the type of block being made. The raw materials are mixed together in a concrete mixer and then poured into a block machine, which forms the blocks. The blocks are then cured and hardened before being ready for use.

5.What is the expected return on investment for a ibm 1000-4 block machine price?

The expected return on investment for a block machine can vary greatly depending on the type of machine, the size of the project, and the market conditions. Generally, block machines can have a return on investment of anywhere from 10-30%, with some machines having returns as high as 50%.

6.Are there any specific safety regulations for operating a ibm 1000-4 block machine price?

Being one of the top ibm 1000-4 block machine price manufacturers in China, We attach great importance to this detail.

Yes, there are specific safety regulations for operating a block machine. These regulations vary depending on the type of block machine and the country in which it is being operated. Generally, safety regulations include wearing protective gear such as safety glasses, gloves, and a hard hat; ensuring that the machine is properly maintained and inspected; and following all safety instructions provided by the manufacturer. Additionally, operators should be trained in the proper use of the machine and be aware of any potential hazards associated with its operation.

7.What is the power source for a ibm 1000-4 block machine price?

Our products & services cover a wide range of areas and meet the needs of different fields.

The power source for a block machine is typically an electric motor. Some block machines may also be powered by a diesel engine.

8.What is the production capacity of a ibm 1000-4 block machine price?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

The production capacity of a block machine depends on the size and type of block being produced. Generally, a block machine can produce between 1,000 and 8,000 blocks per hour.

9.About the scale of ibm 1000-4 block machine price factory

The scale of a block machine factory can vary greatly depending on the type of block machine being produced. Some factories may only produce a few machines, while others may produce hundreds or even thousands of machines. The size of the factory will also depend on the size of the blocks being produced, as well as the number of machines needed to produce them.

10.Can a ibm 1000-4 block machine price be operated continuously or does it require breaks?

Yes, a block machine can be operated continuously, but it is recommended to give it regular breaks to allow for maintenance and repairs.

11.Can a ibm 1000-4 block machine price be used in cold weather conditions?

Yes, a block machine can be used in cold weather conditions. However, it is important to ensure that the machine is properly insulated and heated to prevent any damage from the cold temperatures. Additionally, it is important to ensure that the machine is properly lubricated and maintained to ensure that it is functioning properly in cold weather conditions.

12.About ibm 1000-4 block machine price warranty

Block machine warranties vary depending on the manufacturer and model. Generally, warranties cover defects in materials and workmanship for a certain period of time, usually one year. Some warranties may also cover parts and labor for a certain period of time. It is important to read the warranty information carefully to understand what is covered and for how long.

13.What is the level of precision and accuracy in the production of blocks with a ibm 1000-4 block machine price?

The level of precision and accuracy in the production of blocks with a Block machine depends on the type of machine and the quality of the components used. Generally, modern block machines are capable of producing blocks with a high degree of accuracy and precision. The accuracy of the blocks produced can be further improved by using higher quality components and calibrating the machine regularly.

14.Can a ibm 1000-4 block machine price be operated remotely?

Yes, some block machines can be operated remotely. This is usually done through a computer or mobile device, and the machine can be programmed to run automatically.

15.Can a ibm 1000-4 block machine price produce different sized blocks?

ibm 1000-4 block machine price is not a product only, but also can help you comes to money-making.

Yes, a block machine can produce different sized blocks. Depending on the type of block machine, it can be adjusted to produce blocks of different sizes. Some block machines are designed to produce blocks of a specific size, while others are adjustable to produce blocks of different sizes.

16.Can a ibm 1000-4 block machine price be customized to meet specific production needs?

Our company has many years of ibm 1000-4 block machine price experience and expertise.

Yes, block machines can be customized to meet specific production needs. Depending on the type of block machine, customization may include changing the size of the blocks, the speed of the machine, or the type of material used. Additionally, some block machines can be programmed to produce blocks with specific shapes or sizes.