- 17

- May

Automatic Block Machine basics and configuration

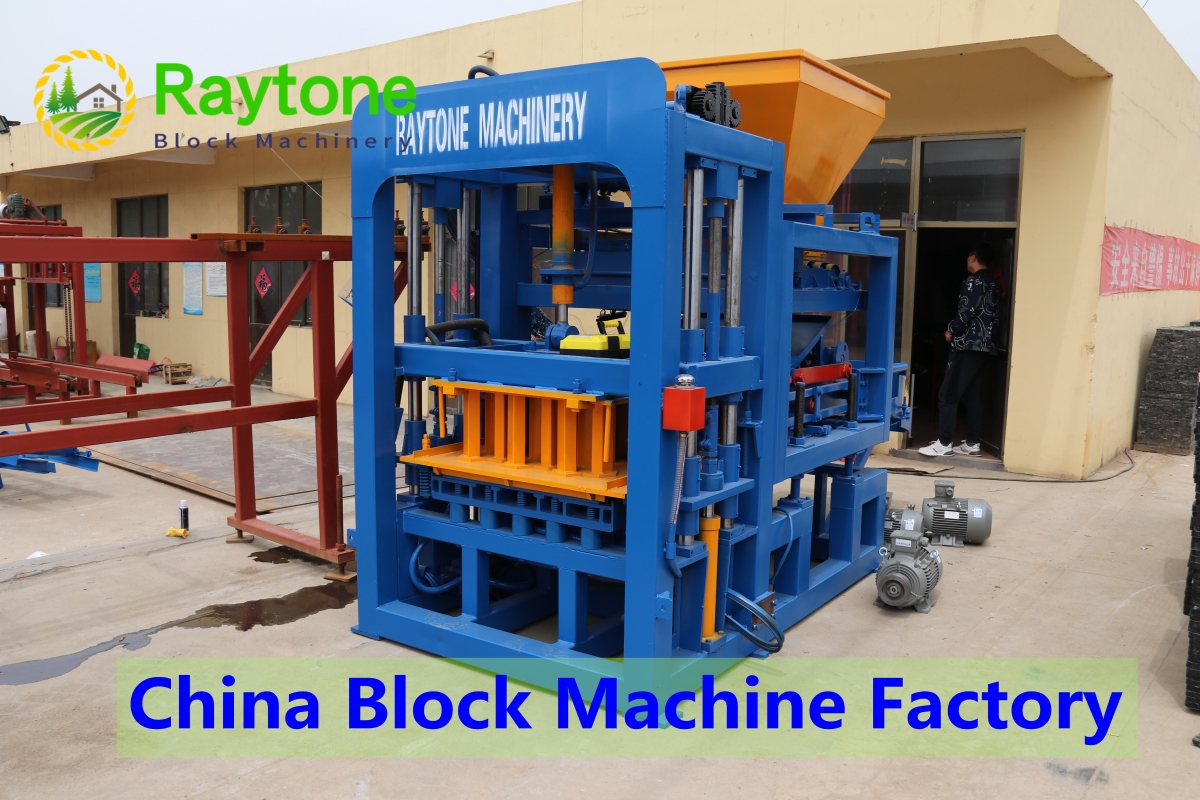

Block making machine is an essential piece of equipment for any construction project. It is used to produce a wide variety of blocks for building walls, pavements, and other structures. With the advancement of technology, the block making machine has evolved from a traditional manual machine to a highly efficient and automatic one. Among the top manufacturers of block making machines, RAYTONE stands out as a trusted and reliable brand in the market. In this article, we will explore the basics and configuration of Automatic Block Machine range.

Established for over 20 years, Raytone Machinery has been a pioneer in the construction industry, supplying high quality block making machines to customers around the world.Their machines are known for their durability, efficiency, and cost-effectiveness, making them the preferred choice for many construction companies.

What is an automatic block machine?

An automatic block machine is a piece of equipment that is used to manufacture concrete blocks in large quantities. These machines use a hydraulic system to compress and mold concrete into various shapes and sizes, which can be used for different building purposes. The automatic block machines are equipped with advanced technology and innovative features to ensure superior quality and efficiency in the production of concrete blocks.

QT4-25 Automatic Cement Block Machine

QT12-15 Automatic Block Machine

QT4-18 Block Making Machine

Different types of automatic block

Ⅰ. Multi-functional block machines

RAYTONE offers a range of multi-functional block machines that can produce different types of blocks, including hollow blocks, solid blocks, paving blocks, and curbstones. These machines have the capability of producing blocks of various sizes and shapes, making them suitable for a wide range of building applications.

Ⅱ. Large capacity block machines

For large-scale construction projects, we offers high-capacity block machines that can produce up to 10,000 blocks per hour. These machines are designed to handle heavy-duty operations and can produce a large quantity of blocks in a short period, making them ideal for high-demand projects.

Ⅲ. Mobile block machines

RAYTONE’s mobile block machines are a perfect solution for on-site production of concrete blocks. These machines are compact and can be easily transported from one construction site to another. They are also equipped with a built-in generator, making them suitable for remote areas without access to electricity.

Ⅳ. Interlocking block machines

Interlocking blocks are gaining popularity in the construction industry due to their strength and versatility. RAYTONE’s automatic interlocking block machines have specially designed molds that allow for the interlocking of blocks, eliminating the need for cement mortar and saving time and money on construction projects.

Features and benefits:

High production efficiency

The automatic block machines are equipped with high-performance hydraulic systems and motors, ensuring a fast and efficient production process. With the capability of producing up to 30 blocks per minute, these machines can significantly increase the production capacity of a construction project.

Versatility

These machines can be adjusted to produce different types and sizes of blocks, making them suitable for various construction projects. This feature also makes it easy to switch between different types of blocks, maximizing the efficiency of the machine.

Easy to operate

The automatic block machines are designed with user-friendliness in mind. With a simple and intuitive control panel, these machines are easy to operate, even for those with no prior experience. The machines also come with a detailed manual and training videos for guidance, ensuring smooth operation.

Durable and reliable

These automatic block machines are built with high-quality materials and components, making them robust and long-lasting. The hydraulic system is designed to withstand heavy use, and the molds are made from wear-resistant steel, ensuring consistent and reliable block production.

Energy-efficient and eco-friendly

RAYTONE’s automatic block machines are designed to consume less energy compared to traditional block making methods. The machines have a low power consumption and are equipped with energy-saving motors, helping businesses reduce their carbon footprint and energy costs.

Low maintenance

The automatic block machines have a simple and compact design, making them easy to maintain. They require minimal maintenance, and all critical parts are easily accessible for quick and hassle-free servicing.

Automatic block machines offer an efficient, reliable, and cost-effective solution for producing high-quality concrete blocks. With advanced technology and innovative features, these machines are a valuable addition to any construction project, helping businesses streamline the block production process and achieve higher profit margins. Choose RAYTONE for your automatic block machine needs and experience the best in quality and efficiency.

Large Automatic Block Machine vs Middle Automatic Block Machine

A large automatic block machine is a machine that is larger in size and has a higher production capacity compared to a standard automatic block machine. These machines are typically used for large-scale commercial or industrial construction projects, where a high volume of blocks or bricks is required.

A middle automatic block machine is a medium-sized machine that falls between the standard and large automatic block machines in terms of size and production capacity. These machines are suitable for medium-sized construction projects or for smaller businesses that require a moderate amount of blocks or bricks.

The main difference between these three types of automatic block machines is their size and production capacity. The larger the machine, the more blocks it can produce at a time. Therefore, the choice of which type of machine to use will depend on the specific needs and scale of the construction project or business.

Another factor to consider is the cost. Large automatic block machines are more expensive compared to standard and middle automatic block machines. They also require more space to operate and may have higher maintenance costs.