- 20

- Dec

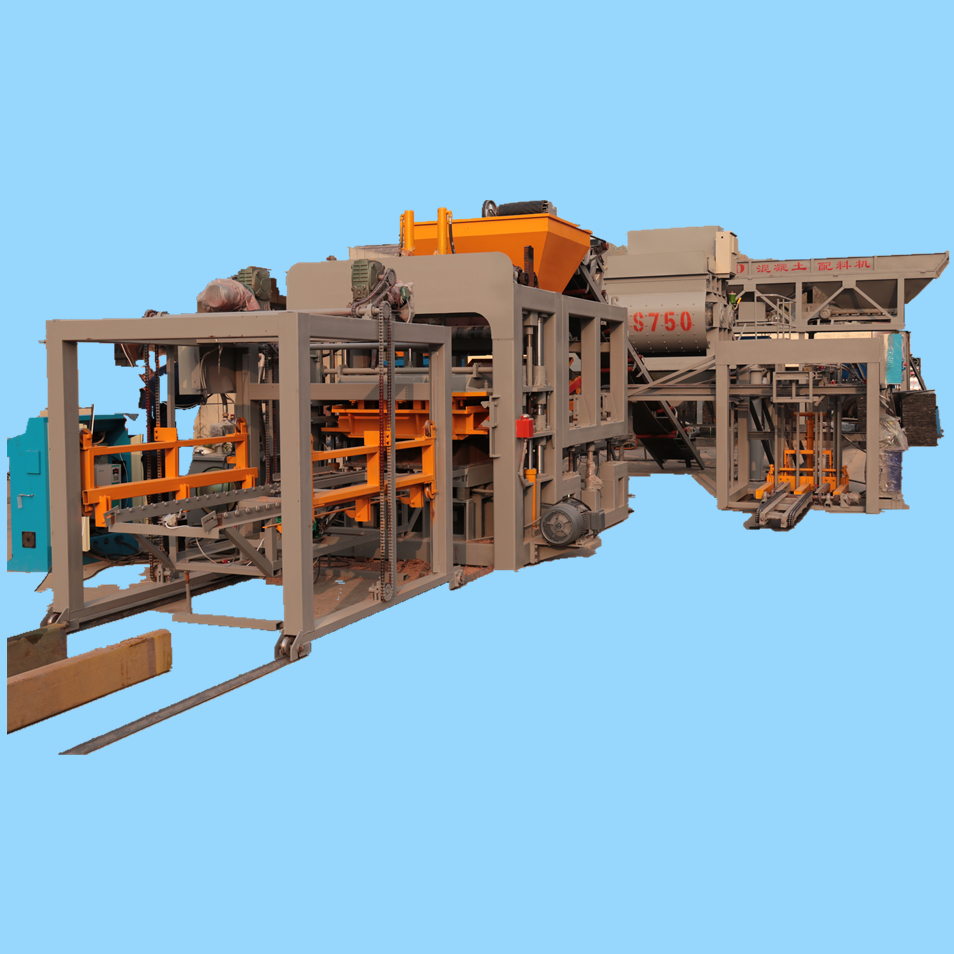

automatic hollow brick block machine

automatic hollow brick block machine come in all shapes and sizes, some are High efficiency and some are mobile. They work by mixing cement, water and aggregates such as Basalt or gravel, and then molding the resulting mixture into blocks. The blocks are then cured and dried before being used.

One of the main advantages of using a block machine is the speed and efficiency with which it produces blocks. By using modern technology, these machines are capable of producing hundreds of blocks per hour, significantly reducing the time and labor required by traditional block manufacturing methods.

Equipped with a durable and robust frame, our automatic hollow brick block machine is able to withstand heavy-duty usage and deliver consistent and high-quality results. The model comes in various configurations to cater to different productivity needs, with options for manual or automatic operation.

In terms of parameters, the Block Machine has a maximum pressure of 1434kN, and its vibration frequency can be adjusted from 0-81Hz. It can handle raw materials such as sand, cement, gravel, and fly ash, with a maximum particle size of 10mm. The machine’s power supply is customizable according to the customer’s requirements, and it has a low power consumption of 19.65 kW.

Furthermore, our automatic hollow brick block machine is equipped with an advanced control system that ensures smooth and accurate operation. It also has a large hopper capacity, reducing the need for frequent refilling and increasing production efficiency.

| Size (mm) | Qty/mould | mould cycle (s) | capacity per hour | daily capacity |

| hollow 400*200*200 | 6 | 20-25 s | 850-1100 | 7843-8800 |

| hollow 400*150*200 | 7 | 20-25 s | 1000-1300 | 7757-10400 |

| hollow 400*100*200 | 18 | 20-25 s | 1200-1400 | 8587-11200 |

Block Machines Redefining Building Standards

automatic hollow brick block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.Are there any safety features built into the design of a automatic hollow brick block machine?

3.How does a automatic hollow brick block machine handle different types of soils?

4.Are there pre-programmed block designs available for a automatic hollow brick block machine?

5.About the development history of automatic hollow brick block machine factory

6.Can a automatic hollow brick block machine be operated by one person?

7.How long does it take to produce a block with a automatic hollow brick block machine?

8.How does a automatic hollow brick block machine deal with unwanted air pockets in the blocks?

9.What are the maintenance costs associated with running a automatic hollow brick block machine?

10.About automatic hollow brick block machine origin

11.What materials are commonly used in a automatic hollow brick block machine?

12.Is there a specific curing process for blocks produced by a automatic hollow brick block machine?

13.How much space is needed to operate a automatic hollow brick block machine?

14.What is the lifespan of a automatic hollow brick block machine?

15.Can a automatic hollow brick block machine produce eco-friendly blocks?

16.What is the cost-effectiveness of using a automatic hollow brick block machine?

1.About the scale of automatic hollow brick block machine factory

The scale of a block machine factory can vary greatly depending on the type of block machine being produced. Some factories may only produce a few machines, while others may produce hundreds or even thousands of machines. The size of the factory will also depend on the size of the blocks being produced, as well as the number of machines needed to produce them.

2.Are there any safety features built into the design of a automatic hollow brick block machine?

Yes, there are several safety features built into the design of a block machine. These include emergency stop buttons, safety guards, and interlocks to prevent accidental operation. Additionally, many block machines are designed with a low center of gravity to reduce the risk of tipping over.

3.How does a automatic hollow brick block machine handle different types of soils?

A block machine is designed to handle a variety of soils, including clay, sand, gravel, and other aggregates. Depending on the type of soil, the machine may need to be adjusted to ensure the blocks are formed correctly. For example, if the soil is clay-based, the machine may need to be adjusted to increase the pressure and vibration to ensure the blocks are formed correctly. Additionally, the machine may need to be adjusted to ensure the blocks are formed with the correct amount of moisture.

4.Are there pre-programmed block designs available for a automatic hollow brick block machine?

We operate our automatic hollow brick block machine business with integrity and honesty.

Yes, some block machines come with pre-programmed block designs. However, many block machines also allow users to create their own custom designs.

5.About the development history of automatic hollow brick block machine factory

The development history of block machine factory can be traced back to the early 20th century. The first block machine was invented in the United States in 1905 by a man named Charles Pankow. This machine was used to make concrete blocks for construction projects. In the 1920s, the first automatic block machine was developed in Germany. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines.

In the 1950s, the first hydraulic block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines. In the 1960s, the first computer-controlled block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines.

In the 1970s, the first fully automated block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines. In the 1980s, the first robotic block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines.

Today, block machine factories are used to produce a wide variety of blocks for construction projects. They are used to produce blocks for residential, commercial, and industrial projects. Block machine factories are also used to produce blocks for landscaping projects.

6.Can a automatic hollow brick block machine be operated by one person?

Yes, a block machine can be operated by one person. However, it is recommended that two people operate the machine for safety reasons.

7.How long does it take to produce a block with a automatic hollow brick block machine?

Our mission is to provide customers with the best solutions for automatic hollow brick block machine.

The time it takes to produce a block with a block machine depends on the size and type of block being produced. Generally, it takes between 10 and 30 seconds to produce a single block.

8.How does a automatic hollow brick block machine deal with unwanted air pockets in the blocks?

A block machine typically has a vibration system that helps to remove any unwanted air pockets in the blocks. The vibration system helps to compact the material and fill any voids that may be present. The vibration system also helps to ensure that the blocks are of a consistent density and strength.

9.What are the maintenance costs associated with running a automatic hollow brick block machine?

The maintenance costs associated with running a Block machine will vary depending on the type of machine and its age. Generally, maintenance costs can include regular oil changes, filter replacements, lubrication, and other routine maintenance. Additionally, more complex repairs such as replacing worn parts or repairing electrical components may be necessary. Depending on the machine, these repairs can be costly.

10.About automatic hollow brick block machine origin

Block machine origin dates back to the late 19th century when the first concrete block machines were developed. The first machines were used to produce concrete blocks for the construction of buildings and other structures. The machines were developed to increase the speed and efficiency of the production process. Over the years, the technology has advanced and the machines have become more sophisticated and efficient. Today, block machines are used in a variety of industries, including construction, manufacturing, and mining.

11.What materials are commonly used in a automatic hollow brick block machine?

Our mission is to provide customers with the best solutions for automatic hollow brick block machine.

Common materials used in block machines include concrete, sand, gravel, cement, and water. Depending on the type of block being made, other materials such as steel, plastic, and wood may also be used.

12.Is there a specific curing process for blocks produced by a automatic hollow brick block machine?

Yes, there is a specific curing process for blocks produced by a block machine. The curing process typically involves keeping the blocks in a moist environment for a period of time, usually between 7 and 28 days. This allows the blocks to dry slowly and evenly, which helps to ensure that they are strong and durable.

13.How much space is needed to operate a automatic hollow brick block machine?

We have established a good reputation and reliable partnerships within the automatic hollow brick block machine industry.

The amount of space needed to operate a block machine will depend on the size and type of machine. Generally, a block machine will require a minimum of 10 feet by 10 feet of space.

14.What is the lifespan of a automatic hollow brick block machine?

Our products & services cover a wide range of areas and meet the needs of different fields.

The lifespan of a block machine can vary depending on the type of machine and how it is used. Generally, block machines can last anywhere from 10 to 20 years with proper maintenance.

15.Can a automatic hollow brick block machine produce eco-friendly blocks?

As one of the automatic hollow brick block machine market leaders, we are known for innovation and reliability.

Yes, a block machine can produce eco-friendly blocks. Many block machines are designed to produce blocks that are made from recycled materials, such as plastic, glass, and other materials. These blocks are often referred to as green blocks” and are becoming increasingly popular as a sustainable building material.”

16.What is the cost-effectiveness of using a automatic hollow brick block machine?

The cost-effectiveness of using a block machine depends on the type of block machine being used, the size of the project, and the amount of labor required. Generally, block machines are more cost-effective than traditional methods of block production, as they require less labor and can produce more blocks in a shorter amount of time. Additionally, block machines can produce blocks with a higher degree of accuracy and uniformity than traditional methods, which can result in a higher quality product.