- 20

- Dec

cover block machine

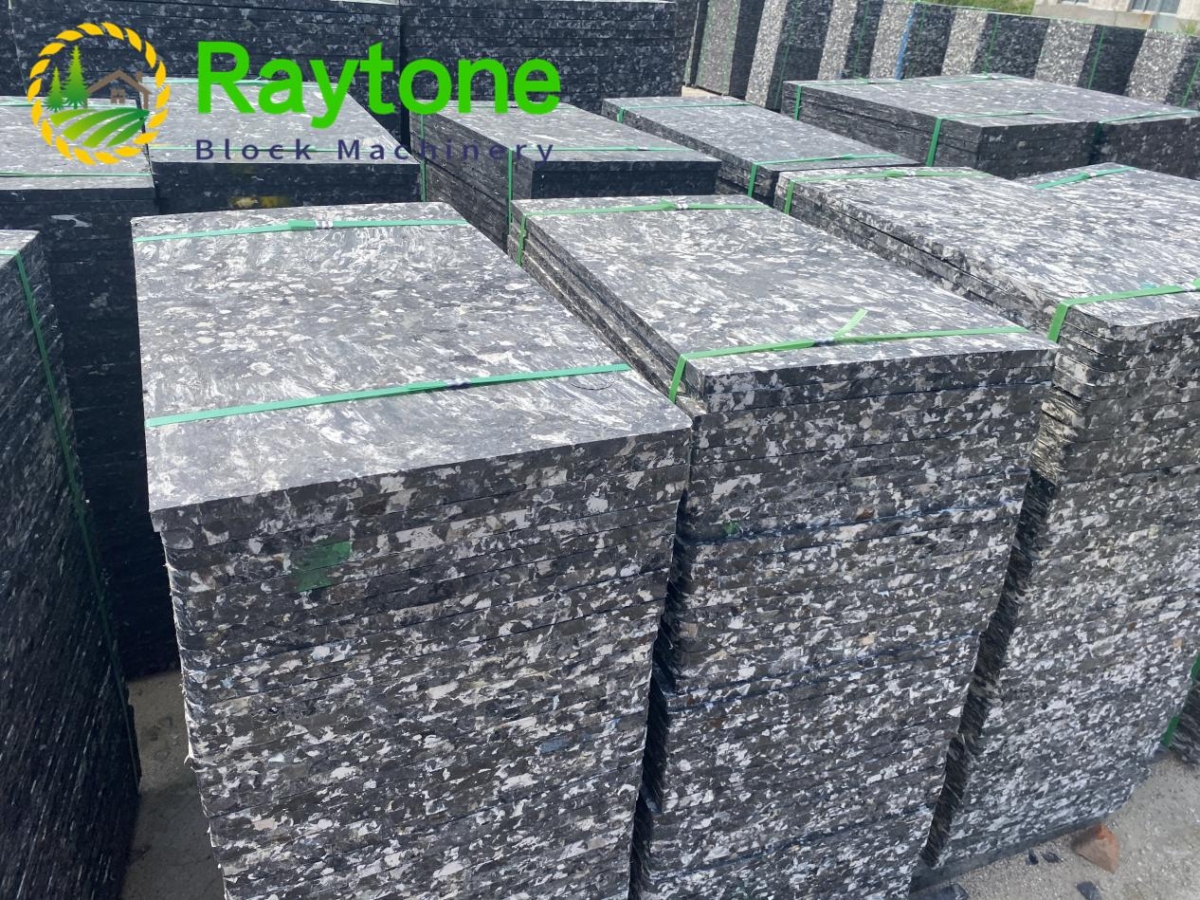

Our cover block machine machines are highly versatile and efficient machines used in the production of Fence blocks

and other related products. We offer both stationary and mobile block making machines to meet the different needs of our customers.

Additionally, our block machines can be customized to meet specific production requirements, allowing our customers to produce unique and high-quality products. We also provide comprehensive after-sales service and technical support to ensure the smooth operation and maintenance of our machines.

Block Machine Technical Specifications:

1. Power: 365V-414V, 64-52Hz, 3 phase

2. Production Capacity: 5705-7723 blocks per hour

3. Block Types: Hollow blocks, solid blocks, paver blocks, and more

4. Block Size: Customizable according to customer needs

5. Weight: Approx. 2537 kg

6. Dimensions: 1874x1307x2840 mm

Our block making machines are the top solution for all your Splash blocks production needs. With its high productivity, durability and versatility, it is the perfect choice for large-scale industrial manufacturing. Contact us today to learn more and start your block production process!

One of the most popular models is the fully automatic cover block machine, which is equipped with advanced technology and can produce blocks of various shapes and sizes with high precision. It has a production capacity of up to 10,000 blocks per hour and can be operated by just one person.

Another model is the semi-automatic cover block machine, which also has a high production capacity of up to 8,000 blocks per hour. It requires some manual labor, but still offers a faster and hassle-free production process.

The manual cover block machine is a budget-friendly option for producing blocks on a smaller scale. It has a production capacity of up to 4,000 blocks per hour and requires more manual labor compared to the other models.

All the models of the cover block machine are equipped with high-quality material and components, ensuring durability and long-lasting performance. They also have adjustable parameters for block size, thickness, and density, allowing for customization according to specific requirements.

| land area | 340 Square Meters | Water Consumption | 2.4 T/day |

| Workshop area | 59 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 3 workers | Power Consumption | 26.5 KW*8 Hours=212 KWH; |

| Cement Consumption | 5.57 Tons per day | Sand consumption | 27.8 tons per day |

| Crushed stones consumption | 30.98 tons per day |

How Block Machines Adapt to Any Project

cover block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.Does a cover block machine have a warranty period?

3.Can a cover block machine be moved easily?

4.About cover block machine production management system

5.About cover block machine raw material procurement system

6.Can a cover block machine be operated continuously or does it require breaks?

7.Can a cover block machine be used in areas with limited access to electricity?

8.What is the level of precision and accuracy in the production of blocks with a cover block machine?

9.How is the weight of a block determined during production?

10.Are there any safety features built into the design of a cover block machine?

11.How does a cover block machine handle different types of soils?

12.Are spare parts readily available for a cover block machine?

13.What is the expected return on investment for a cover block machine?

14.About cover block machine inventory

15.Are there any environmental concerns related to the production of blocks with a cover block machine?

16.How does a cover block machine handle waste materials?

1.About cover block machine technology

Block machine technology is a type of construction technology that is used to produce concrete blocks. It is a process that involves mixing cement, sand, and water to form a concrete mixture, which is then poured into a mold and compressed to form a block. The blocks are then cured and hardened before being used in construction projects. Block machine technology has been used for centuries to create strong and durable structures. It is a cost-effective and efficient way to build structures that are both aesthetically pleasing and structurally sound.

2.Does a cover block machine have a warranty period?

Yes, most block machines come with a warranty period. The length of the warranty period varies depending on the manufacturer and model of the machine.

3.Can a cover block machine be moved easily?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

Yes, block machines can be moved easily. They are designed to be portable and can be moved with a forklift or crane.

4.About cover block machine production management system

The Block machine production management system is a software solution designed to help businesses manage the production of concrete blocks. It provides a comprehensive set of tools to help businesses track and manage the production process from start to finish. The system can be used to monitor production, track inventory, manage orders, and generate reports. It also provides features such as scheduling, cost tracking, and quality control. The system is designed to be user-friendly and can be customized to meet the specific needs of each business.

5.About cover block machine raw material procurement system

A block machine raw material procurement system is a software solution designed to streamline the process of procuring raw materials for the production of concrete blocks. The system automates the process of ordering, tracking, and managing the delivery of raw materials, allowing for greater efficiency and cost savings. The system also provides detailed reporting and analytics to help manufacturers better understand their supply chain and make informed decisions about their raw material procurement.

6.Can a cover block machine be operated continuously or does it require breaks?

Yes, a block machine can be operated continuously, but it is recommended to give it regular breaks to allow for maintenance and repairs.

7.Can a cover block machine be used in areas with limited access to electricity?

We are a professional cover block machine company dedicated to providing high quality products and services.

Yes, some block machines can be used in areas with limited access to electricity. Some block machines are powered by diesel engines, which can be used in areas with limited access to electricity.

8.What is the level of precision and accuracy in the production of blocks with a cover block machine?

The level of precision and accuracy in the production of blocks with a Block machine depends on the type of machine and the quality of the components used. Generally, modern block machines are capable of producing blocks with a high degree of accuracy and precision. The accuracy of the blocks produced can be further improved by using higher quality components and calibrating the machine regularly.

9.How is the weight of a block determined during production?

Our cover block machine products undergo strict quality control to ensure customer satisfaction.

The weight of a block during production is typically determined by a combination of automated and manual processes. Automated processes may include weighing the block on a scale or using a computer-controlled system to measure the weight. Manual processes may include using a hand-held scale or a balance beam.

10.Are there any safety features built into the design of a cover block machine?

Yes, there are several safety features built into the design of a block machine. These include emergency stop buttons, safety guards, and interlocks to prevent accidental operation. Additionally, many block machines are designed with a low center of gravity to reduce the risk of tipping over.

11.How does a cover block machine handle different types of soils?

A block machine is designed to handle a variety of soils, including clay, sand, gravel, and other aggregates. Depending on the type of soil, the machine may need to be adjusted to ensure the blocks are formed correctly. For example, if the soil is clay-based, the machine may need to be adjusted to increase the pressure and vibration to ensure the blocks are formed correctly. Additionally, the machine may need to be adjusted to ensure the blocks are formed with the correct amount of moisture.

12.Are spare parts readily available for a cover block machine?

cover block machine is not a product only, but also can help you comes to money-making.

Yes, spare parts for block machines are readily available. Many manufacturers offer spare parts for their machines, and there are also third-party suppliers that offer spare parts for a variety of block machines.

13.What is the expected return on investment for a cover block machine?

The expected return on investment for a block machine can vary greatly depending on the type of machine, the size of the project, and the market conditions. Generally, block machines can have a return on investment of anywhere from 10-30%, with some machines having returns as high as 50%.

14.About cover block machine inventory

Block machine inventory is a software system designed to help businesses manage their inventory of block machines. The system allows businesses to track the quantity of block machines in stock, the cost of each machine, and the location of each machine. The system also provides reports on the current inventory levels, the cost of each machine, and the location of each machine. Additionally, the system can be used to generate purchase orders and invoices for block machines.

15.Are there any environmental concerns related to the production of blocks with a cover block machine?

Yes, there are environmental concerns related to the production of blocks with a Block machine. The production of blocks with a Block machine can produce dust, noise, and air pollution. Additionally, the production of blocks with a Block machine can also lead to the depletion of natural resources, such as sand and gravel, which are used in the production process.

16.How does a cover block machine handle waste materials?

We focus on innovation and continuous improvement to maintain a competitive advantage.

A block machine is designed to process waste materials into usable building blocks. The machine typically consists of a hopper, a crusher, a mixer, a conveyor, and a press. The hopper is used to feed the waste materials into the crusher, which breaks them down into smaller pieces. The mixer then combines the crushed materials with a binding agent, such as cement, to form a homogenous mixture. The conveyor then transports the mixture to the press, which compresses it into blocks of the desired shape and size. The blocks are then cured and ready for use.