- 20

- Dec

curb stone block machine

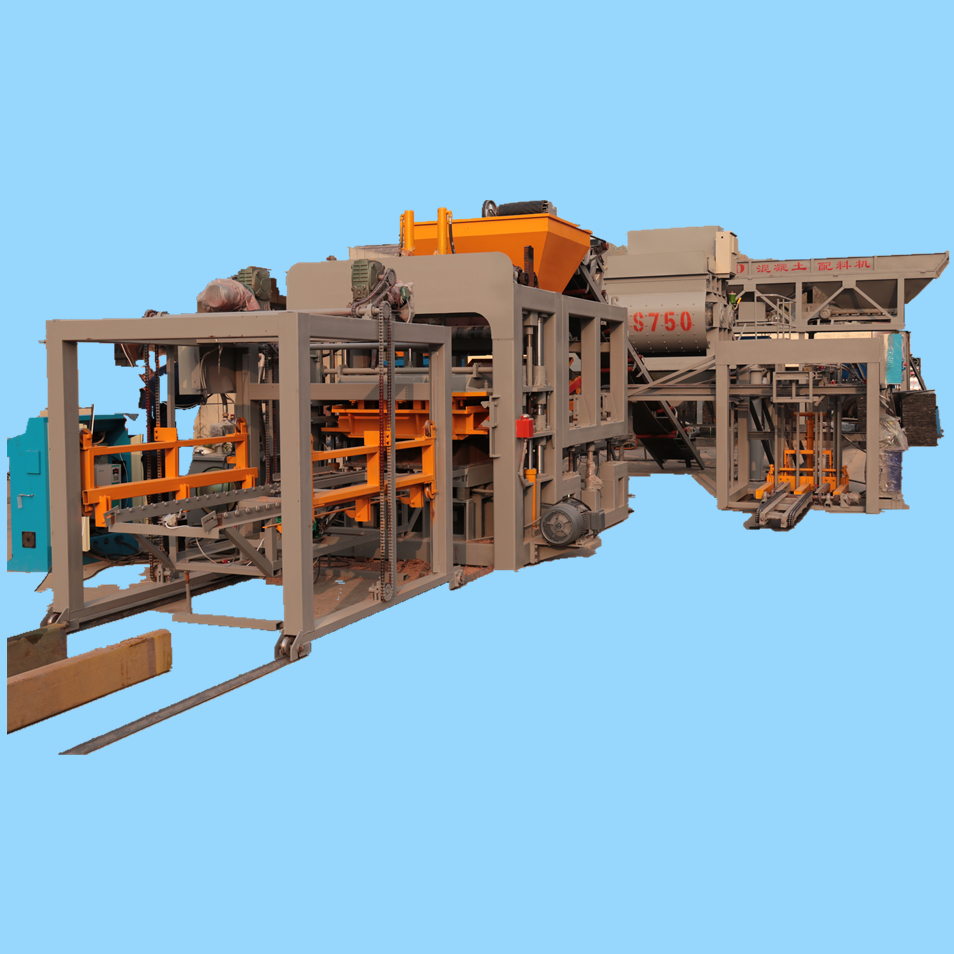

One of our signature products is the fully automatic curb stone block machine, capable of producing different types of blocks, such as hollow blocks, solid blocks, Pier blocksand paving blocks. This machine is highly automated, making it easy to operate and maintain while achieving a high output rate. It is also equipped with a pallet feeder, brick conveyor, and hydraulic system for efficient handling and production.

For those in need of a more versatile machine, we also offer the semi-automatic block machine, which allows for manual control and adjustment of operations. This machine is ideal for small-scale production and can produce various sizes and shapes of concrete blocks.

One of the most impressive features of the Block Machine is its customizable settings. With the ability to adjust the pressure and speed of the machine, users can produce bricks of varying sizes and strength, making it suitable for a wide range of construction needs.In terms of production capacity, the Block Machine can produce up to 8270 bricks per hour, making it ideal for large-scale construction projects. It also comes with a range of additional accessories, such as molds and mixers, to further enhance its capabilities.

| Size (mm) | Qty/mould | mould cycle (s) | capacity per hour | daily capacity |

| hollow 400*200*200 | 6 | 20-25 s | 850-1100 | 6465-8800 |

| hollow 400*150*200 | 7 | 20-25 s | 1000-1300 | 9289-10400 |

| hollow 400*100*200 | 18 | 20-25 s | 1200-1400 | 8141-11200 |

Block Machines Redefining Building Standards

curb stone block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.About curb stone block machine technology

3.Can a curb stone block machine be connected to other construction equipment for seamless production?

4.What is the size and weight of a typical curb stone block machine?

5.What is the cost-effectiveness of using a curb stone block machine?

6.Are there any environmental concerns related to the production of blocks with a curb stone block machine?

7.Does a curb stone block machine have a warranty period?

8.What is the production capacity of a curb stone block machine?

9.What is a curb stone block machine?

10.About curb stone block machine production capacity

11.Can a curb stone block machine be used in combination with other building techniques?

12.Can a curb stone block machine be operated by one person?

13.About curb stone block machine inventory

14.Can a curb stone block machine be used in cold weather conditions?

15.Can a curb stone block machine be customized to meet specific production needs?

1.Are there any safety features built into the design of a curb stone block machine?

Yes, there are several safety features built into the design of a block machine. These include emergency stop buttons, safety guards, and interlocks to prevent accidental operation. Additionally, many block machines are designed with a low center of gravity to reduce the risk of tipping over.

2.About curb stone block machine technology

Block machine technology is a type of construction technology that is used to produce concrete blocks. It is a process that involves mixing cement, sand, and water to form a concrete mixture, which is then poured into a mold and compressed to form a block. The blocks are then cured and hardened before being used in construction projects. Block machine technology has been used for centuries to create strong and durable structures. It is a cost-effective and efficient way to build structures that are both aesthetically pleasing and structurally sound.

3.Can a curb stone block machine be connected to other construction equipment for seamless production?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

Yes, a block machine can be connected to other construction equipment for seamless production. This is done by using a conveyor system to move the blocks from the block machine to other construction equipment, such as a mixer, for further processing. This allows for a more efficient and automated production process.

4.What is the size and weight of a typical curb stone block machine?

The size and weight of a typical block machine will vary depending on the type and model of the machine. Generally, block machines range in size from about 4 feet wide by 8 feet long to 8 feet wide by 20 feet long. The weight of a typical block machine can range from 1,000 to 10,000 pounds.

5.What is the cost-effectiveness of using a curb stone block machine?

The cost-effectiveness of using a block machine depends on the type of block machine being used, the size of the project, and the amount of labor required. Generally, block machines are more cost-effective than traditional methods of block production, as they require less labor and can produce more blocks in a shorter amount of time. Additionally, block machines can produce blocks with a higher degree of accuracy and uniformity than traditional methods, which can result in a higher quality product.

6.Are there any environmental concerns related to the production of blocks with a curb stone block machine?

Yes, there are environmental concerns related to the production of blocks with a Block machine. The production of blocks with a Block machine can produce dust, noise, and air pollution. Additionally, the production of blocks with a Block machine can also lead to the depletion of natural resources, such as sand and gravel, which are used in the production process.

7.Does a curb stone block machine have a warranty period?

Yes, most block machines come with a warranty period. The length of the warranty period varies depending on the manufacturer and model of the machine.

8.What is the production capacity of a curb stone block machine?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

The production capacity of a block machine depends on the size and type of block being produced. Generally, a block machine can produce between 1,000 and 8,000 blocks per hour.

9.What is a curb stone block machine?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

A block machine is a machine used to produce concrete blocks, which are used in the construction of walls, foundations, and other structures. The machine typically consists of a hopper, a conveyor belt, a mold, and a vibration table. The hopper is used to feed the concrete mix into the machine, the conveyor belt transports the mix to the mold, and the vibration table vibrates the mix to ensure a uniform block.

10.About curb stone block machine production capacity

The production capacity of a block machine depends on the size of the blocks it is producing, the type of material being used, and the speed of the machine. Generally, a block machine can produce between 500 and 5,000 blocks per hour.

11.Can a curb stone block machine be used in combination with other building techniques?

Yes, a block machine can be used in combination with other building techniques. For example, a block machine can be used to create the walls of a building, while other building techniques such as steel framing, masonry, and wood framing can be used to create the roof and other structural elements. Additionally, a block machine can be used to create decorative elements such as columns, arches, and other architectural features.

12.Can a curb stone block machine be operated by one person?

Yes, a block machine can be operated by one person. However, it is recommended that two people operate the machine for safety reasons.

13.About curb stone block machine inventory

Block machine inventory is a software system designed to help businesses manage their inventory of block machines. The system allows businesses to track the quantity of block machines in stock, the cost of each machine, and the location of each machine. The system also provides reports on the current inventory levels, the cost of each machine, and the location of each machine. Additionally, the system can be used to generate purchase orders and invoices for block machines.

14.Can a curb stone block machine be used in cold weather conditions?

Yes, a block machine can be used in cold weather conditions. However, it is important to ensure that the machine is properly insulated and heated to prevent any damage from the cold temperatures. Additionally, it is important to ensure that the machine is properly lubricated and maintained to ensure that it is functioning properly in cold weather conditions.

15.Can a curb stone block machine be customized to meet specific production needs?

Our company has many years of curb stone block machine experience and expertise.

Yes, block machines can be customized to meet specific production needs. Depending on the type of block machine, customization may include changing the size of the blocks, the speed of the machine, or the type of material used. Additionally, some block machines can be programmed to produce blocks with specific shapes or sizes.