- 20

- Dec

gypsum board wall block machine

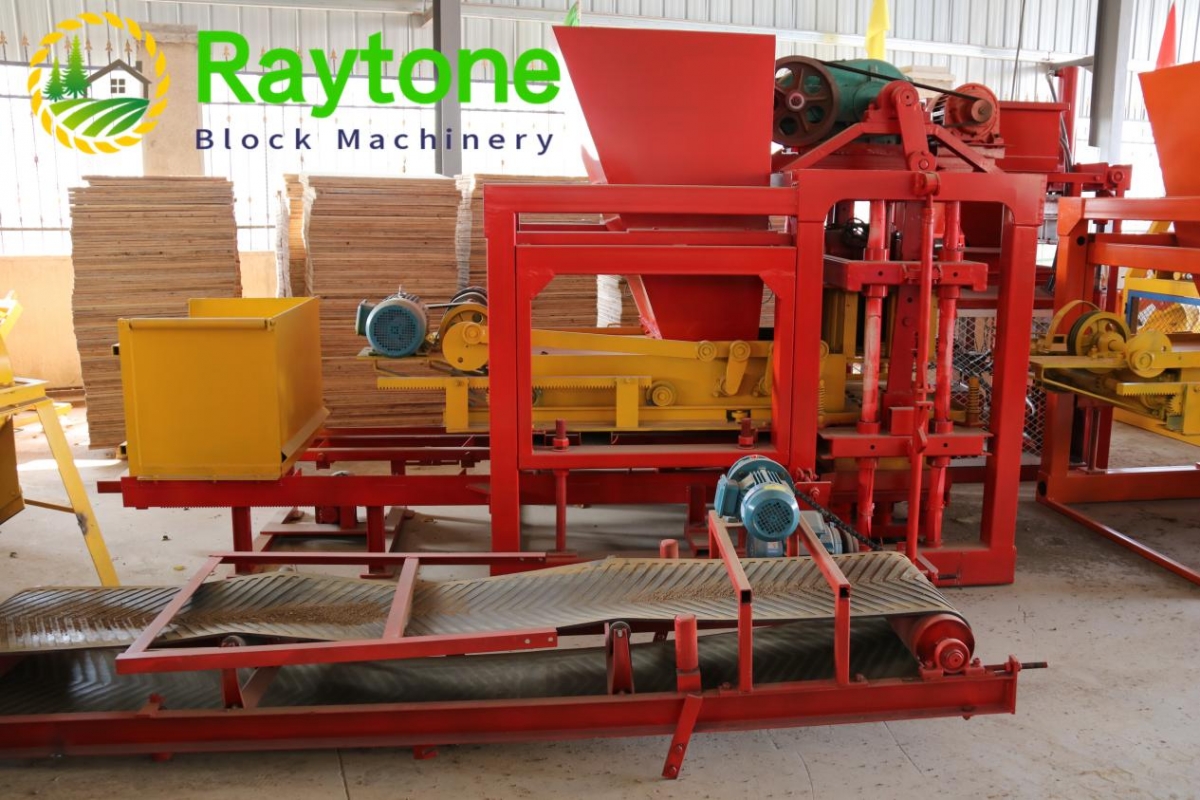

Block machines are essential equipment for the construction industry, enabling the production of high-quality concrete blocks quickly and efficiently. As a leading block machine manufacturer, we specialize in the design, development, and production of top-of-the-line gypsum board wall block machine for a wide range of applications.

Our block machines are equipped with advanced technology and precision engineering, ensuring reliable and consistent performance. They are designed to meet the demands of various markets, including residential, commercial, and industrial construction, Farm and agricultural building constructionwait.

Equipped with a durable and robust frame, our gypsum board wall block machine is able to withstand heavy-duty usage and deliver consistent and high-quality results. The model comes in various configurations to cater to different productivity needs, with options for manual or automatic operation.

In terms of parameters, the Block Machine has a maximum pressure of 1871kN, and its vibration frequency can be adjusted from 0-74Hz. It can handle raw materials such as sand, cement, gravel, and fly ash, with a maximum particle size of 10mm. The machine’s power supply is customizable according to the customer’s requirements, and it has a low power consumption of 20.5 kW.

Furthermore, our gypsum board wall block machine is equipped with an advanced control system that ensures smooth and accurate operation. It also has a large hopper capacity, reducing the need for frequent refilling and increasing production efficiency.

| (1) | Dimension of host machine | 2788*2000*2000mm | (6) | labour | 4 workers |

| (2) | Weight of the host machine | 3.2T | (7) | Voltage | customized |

| (3) | Moulding period | 25-28 | (8) | Total required machine power | 26.5 KW |

| (4) | pallet size | 850*550*20mm | (9) | Diesel Generator capacity | 35.09KVA |

| (5) | Vibration force | 75KN | (10) | workshop area | 442 m2 |

The Advantages of Block Machine Technology

gypsum board wall block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.About gypsum board wall block machine overseas warehouse

3.Does a gypsum board wall block machine require a specific type of raw material?

4.How does a gypsum board wall block machine deal with unwanted air pockets in the blocks?

5.What are the maintenance costs associated with running a gypsum board wall block machine?

6.Can a gypsum board wall block machine produce blocks with varying levels of compressive strength?

7.Can a gypsum board wall block machine be easily repaired in case of breakdown?

8.About gypsum board wall block machine delivery date

9.About gypsum board wall block machine production management system

10.Can a gypsum board wall block machine be used for multiple types of construction projects?

11.About gypsum board wall block machine payment method

12.Can a gypsum board wall block machine be operated continuously or does it require breaks?

1.Can a gypsum board wall block machine be operated manually or automatically?

As one of the gypsum board wall block machine market leaders, we are known for innovation and reliability.

Yes, a block machine can be operated manually or automatically. Manual operation requires an operator to manually feed the material into the machine and manually remove the finished product. Automatic operation requires the machine to be programmed to automatically feed the material and remove the finished product.

2.About gypsum board wall block machine overseas warehouse

Block machine overseas warehouses are warehouses located in different countries around the world that store and distribute block machines. These warehouses are used to store and ship block machines to customers in different countries. The warehouses are typically owned and operated by the block machine manufacturer or distributor. They are responsible for ensuring that the block machines are properly stored and shipped to customers in a timely manner.

3.Does a gypsum board wall block machine require a specific type of raw material?

Our gypsum board wall block machine products undergo strict quality control to ensure customer satisfaction.

Yes, a block machine typically requires a specific type of raw material, such as sand, gravel, cement, and water. Depending on the type of block machine, other materials may also be required.

4.How does a gypsum board wall block machine deal with unwanted air pockets in the blocks?

A block machine typically has a vibration system that helps to remove any unwanted air pockets in the blocks. The vibration system helps to compact the material and fill any voids that may be present. The vibration system also helps to ensure that the blocks are of a consistent density and strength.

5.What are the maintenance costs associated with running a gypsum board wall block machine?

The maintenance costs associated with running a Block machine will vary depending on the type of machine and its age. Generally, maintenance costs can include regular oil changes, filter replacements, lubrication, and other routine maintenance. Additionally, more complex repairs such as replacing worn parts or repairing electrical components may be necessary. Depending on the machine, these repairs can be costly.

6.Can a gypsum board wall block machine produce blocks with varying levels of compressive strength?

Yes, a block machine can produce blocks with varying levels of compressive strength. This is done by adjusting the amount of pressure applied to the blocks during the manufacturing process. The amount of pressure applied can be adjusted to produce blocks with different levels of compressive strength.

7.Can a gypsum board wall block machine be easily repaired in case of breakdown?

Yes, a block machine can be easily repaired in case of breakdown. Depending on the type of block machine, the repair process may involve replacing parts, cleaning and lubricating components, or adjusting settings. In some cases, a technician may need to be called in to diagnose and repair the machine.

8.About gypsum board wall block machine delivery date

The delivery date of a block machine will depend on the type of machine, the manufacturer, and the availability of the machine. Generally, most block machines can be delivered within 4-6 weeks of ordering. However, some manufacturers may have longer lead times due to production schedules or other factors. It is best to contact the manufacturer directly to get an accurate delivery date.

9.About gypsum board wall block machine production management system

The Block machine production management system is a software solution designed to help businesses manage the production of concrete blocks. It provides a comprehensive set of tools to help businesses track and manage the production process from start to finish. The system can be used to monitor production, track inventory, manage orders, and generate reports. It also provides features such as scheduling, cost tracking, and quality control. The system is designed to be user-friendly and can be customized to meet the specific needs of each business.

10.Can a gypsum board wall block machine be used for multiple types of construction projects?

We have established a good reputation and reliable partnerships within the gypsum board wall block machine industry.

Yes, a block machine can be used for multiple types of construction projects. Block machines are versatile and can be used to produce a variety of concrete blocks, including hollow blocks, paving blocks, curbstones, and more. They can also be used to produce other concrete products such as pavers, tiles, and slabs.

11.About gypsum board wall block machine payment method

Block machine payment methods vary depending on the manufacturer and the type of machine. Some common payment methods include cash, credit cards, PayPal, wire transfers, and cryptocurrency. Some manufacturers may also offer financing options or leasing options.

12.Can a gypsum board wall block machine be operated continuously or does it require breaks?

Yes, a block machine can be operated continuously, but it is recommended to give it regular breaks to allow for maintenance and repairs.