- 21

- Dec

plastic block machine

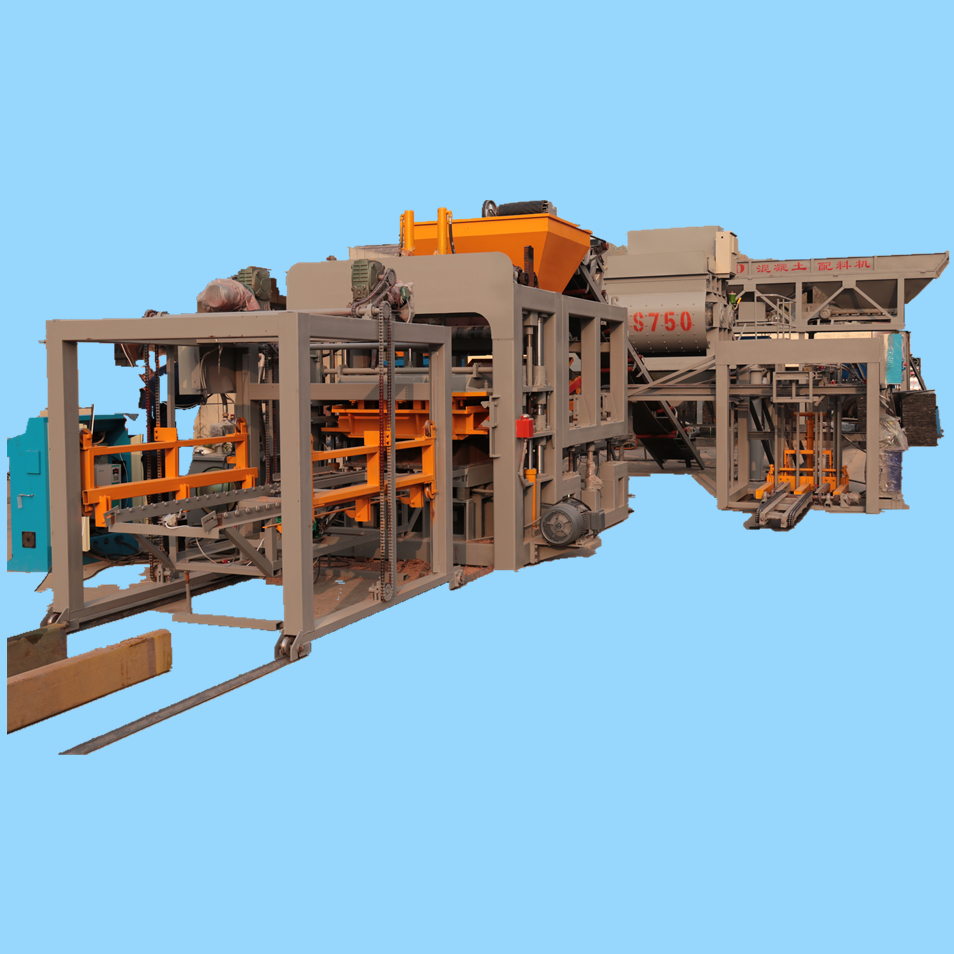

Block machines are essential equipment for the construction industry, enabling the production of high-quality concrete blocks quickly and efficiently. As a leading block machine manufacturer, we specialize in the design, development, and production of top-of-the-line plastic block machine for a wide range of applications.

Our block machines are equipped with advanced technology and precision engineering, ensuring reliable and consistent performance. They are designed to meet the demands of various markets, including residential, commercial, and industrial construction, Irrigation system installationwait.

Equipped with a powerful motor and hydraulic system, the Block Machine is capable of producing up to 10133 bricks per hour. It also features an automatic feeding system, allowing for continuous production without any interruptions. The machine has a PLC control system that ensures precise and accurate production, while also making it user-friendly and easy to operate.

plastic block machine is a type of equipment used for producing concrete blocks in various shapes and sizes. There are different models of plastic block machines available in the market, each with its own unique features and capabilities.

QT6-15 Block Making Machine, which is designed for high production and efficiency. This machine is equipped with a large capacity pallet, allowing it to produce six blocks in one cycle. It also has a high pressure hydraulic system, ensuring strong and stable block compression. The QT6-15 is designed with advanced nozzle and mold vibration technology, resulting in precise and high-quality block production.

QT5-15 Concrete Block Molding Machine, which is suitable for producing various types of concrete blocks, including hollow, solid, and interlocking blocks. It has a powerful vibration system and a multi-source vibration of 360 degrees, which ensures uniform and strong block density. The machine also has a high-speed hydraulic system, allowing for quick and efficient block production.

Both models mentioned above have automatic control systems with PLC and touch screen interface, making it easy to operate and adjust the machine settings. They also have customizable features, such as different molds and block sizes, to cater to various construction needs.

In terms of parameters, the QT6-15 has a production capacity of 8640-11520 blocks per shift, while the QT5-15 can produce 7680-10240 blocks per shift. Both models have a power rating of 27.5 kW and require a voltage of 380V. They also have a weight of approximately 14-15 tons and a compact design for ease of transportation and installation.

| (1) | Dimension of host machine | 2296*2000*2000mm | (6) | labour | 4 workers |

| (2) | Weight of the host machine | 3.2T | (7) | Voltage | customized |

| (3) | Moulding period | 25-28 | (8) | Total required machine power | 26.5 KW |

| (4) | pallet size | 850*550*20mm | (9) | Diesel Generator capacity | 32.95KVA |

| (5) | Vibration force | 44KN | (10) | workshop area | 393 m2 |

The Time-Saving Features of Modern Block Machines

plastic block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.Can a plastic block machine be used to produce other building materials besides blocks?

3.Can a plastic block machine be easily repaired in case of breakdown?

4.How long does it take to produce a block with a plastic block machine?

5.Can a plastic block machine be used for multiple types of construction projects?

6.About plastic block machine production equipment

7.About plastic block machine inventory

8.How is the quality of blocks produced by a plastic block machine ensured?

9.About plastic block machine production skills training

10.Can a plastic block machine be customized to meet specific production needs?

11.What is the size and weight of a typical plastic block machine?

12.About the development history of plastic block machine factory

13.About plastic block machine patent

14.Are there pre-programmed block designs available for a plastic block machine?

15.About plastic block machine raw materials

1.What is the production capacity of a plastic block machine?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

The production capacity of a block machine depends on the size and type of block being produced. Generally, a block machine can produce between 1,000 and 8,000 blocks per hour.

2.Can a plastic block machine be used to produce other building materials besides blocks?

Yes, a block machine can be used to produce other building materials such as pavers, bricks, tiles, and even roof tiles.

3.Can a plastic block machine be easily repaired in case of breakdown?

Yes, a block machine can be easily repaired in case of breakdown. Depending on the type of block machine, the repair process may involve replacing parts, cleaning and lubricating components, or adjusting settings. In some cases, a technician may need to be called in to diagnose and repair the machine.

4.How long does it take to produce a block with a plastic block machine?

Our mission is to provide customers with the best solutions for plastic block machine.

The time it takes to produce a block with a block machine depends on the size and type of block being produced. Generally, it takes between 10 and 30 seconds to produce a single block.

5.Can a plastic block machine be used for multiple types of construction projects?

We have established a good reputation and reliable partnerships within the plastic block machine industry.

Yes, a block machine can be used for multiple types of construction projects. Block machines are versatile and can be used to produce a variety of concrete blocks, including hollow blocks, paving blocks, curbstones, and more. They can also be used to produce other concrete products such as pavers, tiles, and slabs.

6.About plastic block machine production equipment

Block machine production equipment is used to produce concrete blocks, bricks, and other masonry products. This equipment typically includes a mixer, a block machine, a conveyor, and a curing chamber. The mixer is used to mix the concrete, while the block machine is used to form the blocks. The conveyor is used to move the blocks to the curing chamber, where they are cured and hardened. The equipment is typically powered by electricity or diesel fuel.

7.About plastic block machine inventory

Block machine inventory is a software system designed to help businesses manage their inventory of block machines. The system allows businesses to track the quantity of block machines in stock, the cost of each machine, and the location of each machine. The system also provides reports on the current inventory levels, the cost of each machine, and the location of each machine. Additionally, the system can be used to generate purchase orders and invoices for block machines.

8.How is the quality of blocks produced by a plastic block machine ensured?

The quality of blocks produced by a block machine is ensured by using high-quality raw materials, controlling the temperature and pressure of the machine, and using quality control measures such as testing the blocks for strength and durability. Additionally, the machine should be regularly serviced and maintained to ensure that it is operating correctly and producing blocks of the highest quality.

9.About plastic block machine production skills training

Block machine production skills training is a type of training that teaches individuals how to operate and maintain block machines. This type of training is important for those who are looking to start a business in the block machine industry. The training covers topics such as safety, operation, maintenance, troubleshooting, and more. It also provides hands-on experience with the machines so that individuals can gain a better understanding of how they work. This type of training is essential for anyone looking to start a business in the block machine industry.

10.Can a plastic block machine be customized to meet specific production needs?

Our company has many years of plastic block machine experience and expertise.

Yes, block machines can be customized to meet specific production needs. Depending on the type of block machine, customization may include changing the size of the blocks, the speed of the machine, or the type of material used. Additionally, some block machines can be programmed to produce blocks with specific shapes or sizes.

11.What is the size and weight of a typical plastic block machine?

The size and weight of a typical block machine will vary depending on the type and model of the machine. Generally, block machines range in size from about 4 feet wide by 8 feet long to 8 feet wide by 20 feet long. The weight of a typical block machine can range from 1,000 to 10,000 pounds.

12.About the development history of plastic block machine factory

The development history of block machine factory can be traced back to the early 20th century. The first block machine was invented in the United States in 1905 by a man named Charles Pankow. This machine was used to make concrete blocks for construction projects. In the 1920s, the first automatic block machine was developed in Germany. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines.

In the 1950s, the first hydraulic block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines. In the 1960s, the first computer-controlled block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines.

In the 1970s, the first fully automated block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines. In the 1980s, the first robotic block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines.

Today, block machine factories are used to produce a wide variety of blocks for construction projects. They are used to produce blocks for residential, commercial, and industrial projects. Block machine factories are also used to produce blocks for landscaping projects.

13.About plastic block machine patent

Block machine patents are patents that cover the design and operation of machines used to make blocks of various materials, such as concrete, clay, and other masonry materials. These machines are used in the construction industry to create walls, foundations, and other structures. Block machine patents typically cover the design of the machine, the operation of the machine, and the materials used in the production of blocks.

14.Are there pre-programmed block designs available for a plastic block machine?

We operate our plastic block machine business with integrity and honesty.

Yes, some block machines come with pre-programmed block designs. However, many block machines also allow users to create their own custom designs.

15.About plastic block machine raw materials

Block machine raw materials are typically made from a combination of cement, sand, gravel, and water. The exact proportions of each material used will vary depending on the type of block being made. The raw materials are mixed together in a concrete mixer and then poured into a block machine, which forms the blocks. The blocks are then cured and hardened before being ready for use.