- 20

- Dec

concrete block machine cost

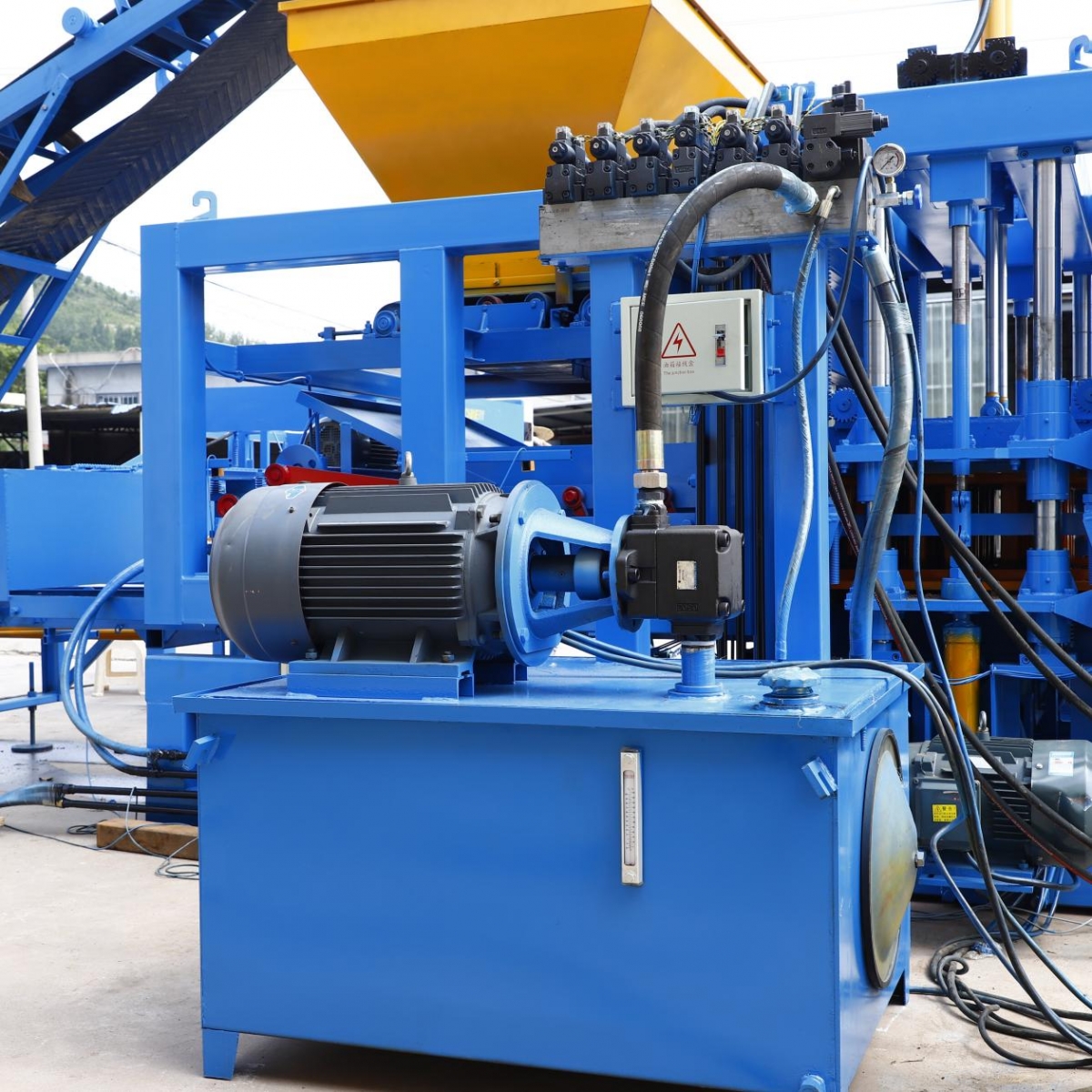

concrete block machine cost come in all shapes and sizes, some are interlocking and some are mobile. They work by mixing cement, water and aggregates such as Terracotta or gravel, and then molding the resulting mixture into blocks. The blocks are then cured and dried before being used.

One of the main advantages of using a block machine is the speed and efficiency with which it produces blocks. By using modern technology, these machines are capable of producing hundreds of blocks per hour, significantly reducing the time and labor required by traditional block manufacturing methods.

Block Machine Technical Specifications:

1. Power: 399V-420V, 56-55Hz, 3 phase

2. Production Capacity: 5358-8729 blocks per hour

3. Block Types: Hollow blocks, solid blocks, paver blocks, and more

4. Block Size: Customizable according to customer needs

5. Weight: Approx. 2478 kg

6. Dimensions: 3022x1689x2939 mm

Our block making machines are the top solution for all your Roadway blocks production needs. With its high productivity, durability and versatility, it is the perfect choice for large-scale industrial manufacturing. Contact us today to learn more and start your block production process!

One of the most popular models is the fully automatic concrete block machine cost, which is equipped with advanced technology and can produce blocks of various shapes and sizes with high precision. It has a production capacity of up to 10,000 blocks per hour and can be operated by just one person.

Another model is the semi-automatic concrete block machine cost, which also has a high production capacity of up to 8,000 blocks per hour. It requires some manual labor, but still offers a faster and hassle-free production process.

The manual concrete block machine cost is a budget-friendly option for producing blocks on a smaller scale. It has a production capacity of up to 4,000 blocks per hour and requires more manual labor compared to the other models.

All the models of the concrete block machine cost are equipped with high-quality material and components, ensuring durability and long-lasting performance. They also have adjustable parameters for block size, thickness, and density, allowing for customization according to specific requirements.

| land area | 254 Square Meters | Water Consumption | 2.4 T/day |

| Workshop area | 57 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 3 workers | Power Consumption | 26.5 KW*8 Hours=212 KWH; |

| Cement Consumption | 8.21 Tons per day | Sand consumption | 29.4 tons per day |

| Crushed stones consumption | 32.85 tons per day |

The Advantages of Block Machine Technology

concrete block machine cost FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.What materials are commonly used in a concrete block machine cost?

3.Does a concrete block machine cost have a warranty period?

4.Are there pre-programmed block designs available for a concrete block machine cost?

5.How often does a concrete block machine cost need to be maintained?

6.About concrete block machine cost MOQ

7.What is the expected return on investment for a concrete block machine cost?

8.Can a concrete block machine cost be used for both indoor and outdoor construction projects?

9.About concrete block machine cost production skills training

10.Can a concrete block machine cost be used for large scale production?

11.About concrete block machine cost production equipment

12.About concrete block machine cost raw materials

13.Are there any environmental concerns related to the production of blocks with a concrete block machine cost?

1.What is the cost-effectiveness of using a concrete block machine cost?

The cost-effectiveness of using a block machine depends on the type of block machine being used, the size of the project, and the amount of labor required. Generally, block machines are more cost-effective than traditional methods of block production, as they require less labor and can produce more blocks in a shorter amount of time. Additionally, block machines can produce blocks with a higher degree of accuracy and uniformity than traditional methods, which can result in a higher quality product.

2.What materials are commonly used in a concrete block machine cost?

Our mission is to provide customers with the best solutions for concrete block machine cost.

Common materials used in block machines include concrete, sand, gravel, cement, and water. Depending on the type of block being made, other materials such as steel, plastic, and wood may also be used.

3.Does a concrete block machine cost have a warranty period?

Yes, most block machines come with a warranty period. The length of the warranty period varies depending on the manufacturer and model of the machine.

4.Are there pre-programmed block designs available for a concrete block machine cost?

We operate our concrete block machine cost business with integrity and honesty.

Yes, some block machines come with pre-programmed block designs. However, many block machines also allow users to create their own custom designs.

5.How often does a concrete block machine cost need to be maintained?

We focus on innovation and continuous improvement to maintain a competitive advantage.

A block machine should be maintained on a regular basis, typically every 3-6 months depending on the type of machine and its usage. Regular maintenance should include checking for wear and tear, lubricating moving parts, and inspecting the machine for any potential safety hazards.

6.About concrete block machine cost MOQ

The minimum order quantity (MOQ) for a block machine will vary depending on the type of machine and the manufacturer. Generally, the MOQ for a block machine is one unit. However, some manufacturers may require a minimum order of multiple units.

7.What is the expected return on investment for a concrete block machine cost?

The expected return on investment for a block machine can vary greatly depending on the type of machine, the size of the project, and the market conditions. Generally, block machines can have a return on investment of anywhere from 10-30%, with some machines having returns as high as 50%.

8.Can a concrete block machine cost be used for both indoor and outdoor construction projects?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

Yes, a block machine can be used for both indoor and outdoor construction projects. However, the type of block machine used will depend on the specific project requirements. For example, a block machine designed for outdoor projects may be more powerful and durable than one designed for indoor projects.

9.About concrete block machine cost production skills training

Block machine production skills training is a type of training that teaches individuals how to operate and maintain block machines. This type of training is important for those who are looking to start a business in the block machine industry. The training covers topics such as safety, operation, maintenance, troubleshooting, and more. It also provides hands-on experience with the machines so that individuals can gain a better understanding of how they work. This type of training is essential for anyone looking to start a business in the block machine industry.

10.Can a concrete block machine cost be used for large scale production?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, block machines can be used for large scale production. Block machines are designed to produce large quantities of concrete blocks in a short amount of time. They are typically used in the construction industry to produce blocks for walls, foundations, and other structures.

11.About concrete block machine cost production equipment

Block machine production equipment is used to produce concrete blocks, bricks, and other masonry products. This equipment typically includes a mixer, a block machine, a conveyor, and a curing chamber. The mixer is used to mix the concrete, while the block machine is used to form the blocks. The conveyor is used to move the blocks to the curing chamber, where they are cured and hardened. The equipment is typically powered by electricity or diesel fuel.

12.About concrete block machine cost raw materials

Block machine raw materials are typically made from a combination of cement, sand, gravel, and water. The exact proportions of each material used will vary depending on the type of block being made. The raw materials are mixed together in a concrete mixer and then poured into a block machine, which forms the blocks. The blocks are then cured and hardened before being ready for use.

13.Are there any environmental concerns related to the production of blocks with a concrete block machine cost?

Yes, there are environmental concerns related to the production of blocks with a Block machine. The production of blocks with a Block machine can produce dust, noise, and air pollution. Additionally, the production of blocks with a Block machine can also lead to the depletion of natural resources, such as sand and gravel, which are used in the production process.