- 21

- Dec

ibm 3000 block machine

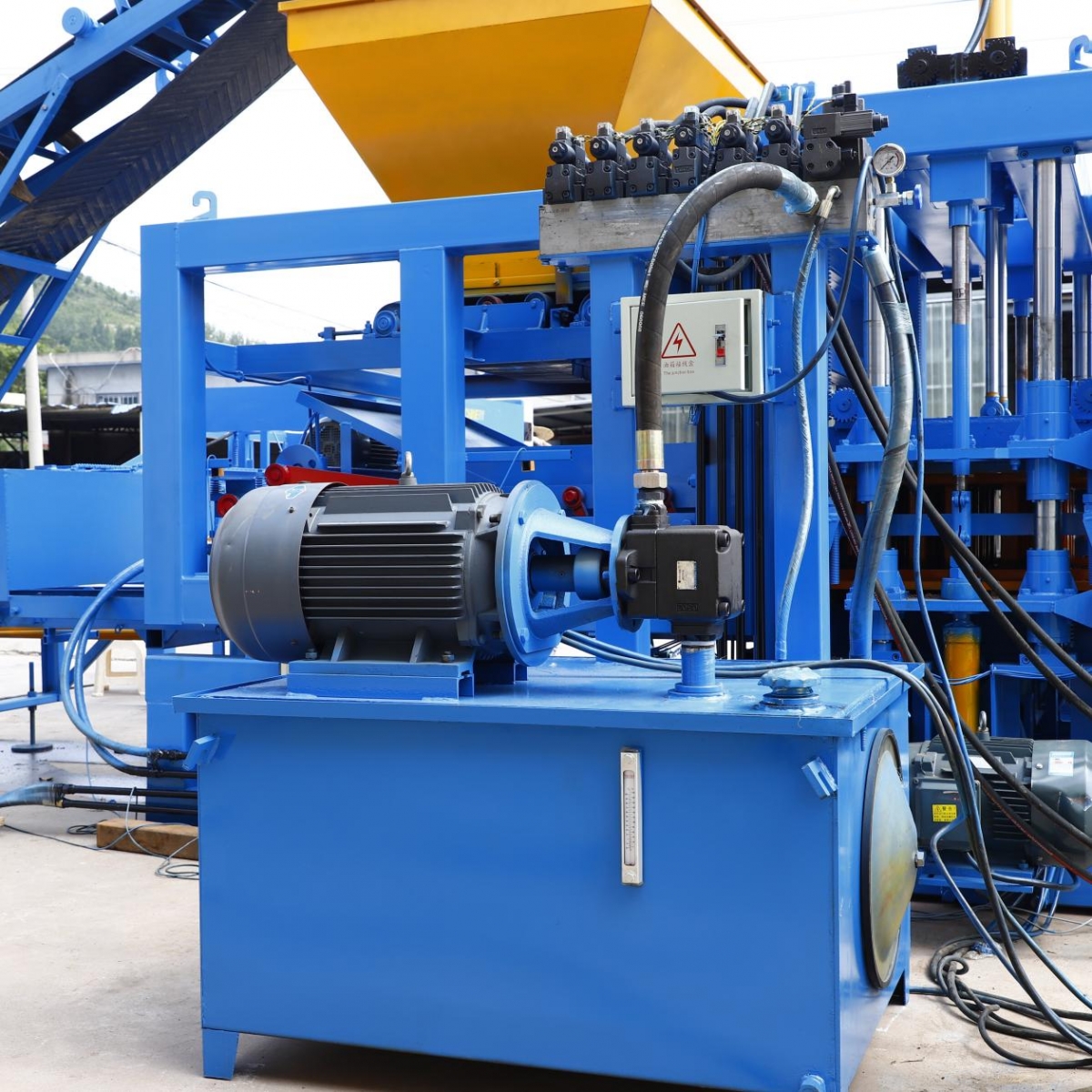

One of our signature products is the fully automatic ibm 3000 block machine, capable of producing different types of blocks, such as hollow blocks, solid blocks, Culvert blocksand paving blocks. This machine is highly automated, making it easy to operate and maintain while achieving a high output rate. It is also equipped with a pallet feeder, brick conveyor, and hydraulic system for efficient handling and production.

For those in need of a more versatile machine, we also offer the semi-automatic block machine, which allows for manual control and adjustment of operations. This machine is ideal for small-scale production and can produce various sizes and shapes of concrete blocks.

Our ibm 3000 block machine is available in various models and comes with a range of different parameters to cater to your specific needs. The models include the QMJ4-35, QTJ4-26C, QT5-15, and QT8-15, each offering unique features and capabilities.

The QMJ4-35 model is a small and compact machine, ideal for projects with limited space. It has a production capacity of 400 to $keyworrd{36} blocks per hour and a power consumption of 11.25 kW. The QTJ4-26C model is an upgraded version with a higher production capacity of 800 to 1597 blocks per hour and a lower power consumption of 9.6 kW.

For larger projects, the QT5-15 model is a perfect choice with a production capacity of 7120 to 8398 blocks per 8 hours, and a power consumption of 21 kW. It also comes with a hydraulic system for more efficient and precise operation. The QT8-15 model is our most advanced and largest model, with a production capacity of 9600 to 12000 blocks per 8 hours and a power consumption of 51 kW. It also has an intelligent PLC control system for automated operation.

In addition to these models, we offer various configurations for different block sizes and shapes, such as hollow blocks, solid blocks, and interlocking blocks. Our ibm 3000 block machine is also equipped with high-quality motors and hydraulic components for reliable and durable performance. With our customizable options and reliable technology, our ibm 3000 block machine is the perfect solution for all your block-making needs.

| Feeding Capacity | 602L | Discharging Capacity | 515L |

| Depth | 0.5m | Motor Power | 11kw |

| Overall Size | 1500L*1500W*1350H (mm) | Diameter | 1500mm |

| Reducer | 345 reducer/ truck rear axle gear | Weight |

800kg |

Maximizing Structural Strength with Block Machines

ibm 3000 block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.Can a ibm 3000 block machine be used for large scale production?

3.Are there any noise or vibration concerns with a ibm 3000 block machine?

4.What materials are commonly used in a ibm 3000 block machine?

5.About ibm 3000 block machine MOQ

6.How long does it take to produce a block with a ibm 3000 block machine?

7.How does the cost of a ibm 3000 block machine compare to traditional building materials?

8.Can a ibm 3000 block machine produce blocks with varying levels of compressive strength?

9.Can a ibm 3000 block machine be used for both indoor and outdoor construction projects?

10.What is a ibm 3000 block machine?

11.Are spare parts readily available for a ibm 3000 block machine?

12.Can a ibm 3000 block machine produce blocks of varying shapes?

13.Can a ibm 3000 block machine be easily repaired in case of breakdown?

1.Is a ibm 3000 block machine easy to operate?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

Yes, most block machines are designed to be easy to operate. Many modern block machines are automated and require minimal operator input. However, some block machines may require more operator input and knowledge to operate correctly.

2.Can a ibm 3000 block machine be used for large scale production?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, block machines can be used for large scale production. Block machines are designed to produce large quantities of concrete blocks in a short amount of time. They are typically used in the construction industry to produce blocks for walls, foundations, and other structures.

3.Are there any noise or vibration concerns with a ibm 3000 block machine?

Yes, noise and vibration are common concerns with block machines. The noise and vibration levels can vary depending on the type of machine and the materials being used. It is important to ensure that the machine is properly maintained and that the operator is properly trained to reduce the risk of excessive noise and vibration.

4.What materials are commonly used in a ibm 3000 block machine?

Our mission is to provide customers with the best solutions for ibm 3000 block machine.

Common materials used in block machines include concrete, sand, gravel, cement, and water. Depending on the type of block being made, other materials such as steel, plastic, and wood may also be used.

5.About ibm 3000 block machine MOQ

The minimum order quantity (MOQ) for a block machine will vary depending on the type of machine and the manufacturer. Generally, the MOQ for a block machine is one unit. However, some manufacturers may require a minimum order of multiple units.

6.How long does it take to produce a block with a ibm 3000 block machine?

Our mission is to provide customers with the best solutions for ibm 3000 block machine.

The time it takes to produce a block with a block machine depends on the size and type of block being produced. Generally, it takes between 10 and 30 seconds to produce a single block.

7.How does the cost of a ibm 3000 block machine compare to traditional building materials?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

The cost of a block machine is typically much higher than traditional building materials. Block machines are typically used to produce large quantities of blocks, which can be expensive to purchase in bulk. Additionally, block machines require specialized equipment and expertise to operate, which can add to the cost.

8.Can a ibm 3000 block machine produce blocks with varying levels of compressive strength?

Yes, a block machine can produce blocks with varying levels of compressive strength. This is done by adjusting the amount of pressure applied to the blocks during the manufacturing process. The amount of pressure applied can be adjusted to produce blocks with different levels of compressive strength.

9.Can a ibm 3000 block machine be used for both indoor and outdoor construction projects?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

Yes, a block machine can be used for both indoor and outdoor construction projects. However, the type of block machine used will depend on the specific project requirements. For example, a block machine designed for outdoor projects may be more powerful and durable than one designed for indoor projects.

10.What is a ibm 3000 block machine?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

A block machine is a machine used to produce concrete blocks, which are used in the construction of walls, foundations, and other structures. The machine typically consists of a hopper, a conveyor belt, a mold, and a vibration table. The hopper is used to feed the concrete mix into the machine, the conveyor belt transports the mix to the mold, and the vibration table vibrates the mix to ensure a uniform block.

11.Are spare parts readily available for a ibm 3000 block machine?

ibm 3000 block machine is not a product only, but also can help you comes to money-making.

Yes, spare parts for block machines are readily available. Many manufacturers offer spare parts for their machines, and there are also third-party suppliers that offer spare parts for a variety of block machines.

12.Can a ibm 3000 block machine produce blocks of varying shapes?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, a block machine can produce blocks of varying shapes. Block machines are designed to produce blocks of different sizes and shapes, depending on the type of block machine and the type of block being produced. Some block machines are capable of producing blocks with complex shapes, such as interlocking blocks, while others are limited to producing blocks with basic shapes, such as rectangular blocks.

13.Can a ibm 3000 block machine be easily repaired in case of breakdown?

Yes, a block machine can be easily repaired in case of breakdown. Depending on the type of block machine, the repair process may involve replacing parts, cleaning and lubricating components, or adjusting settings. In some cases, a technician may need to be called in to diagnose and repair the machine.