- 21

- Dec

shengya block machine

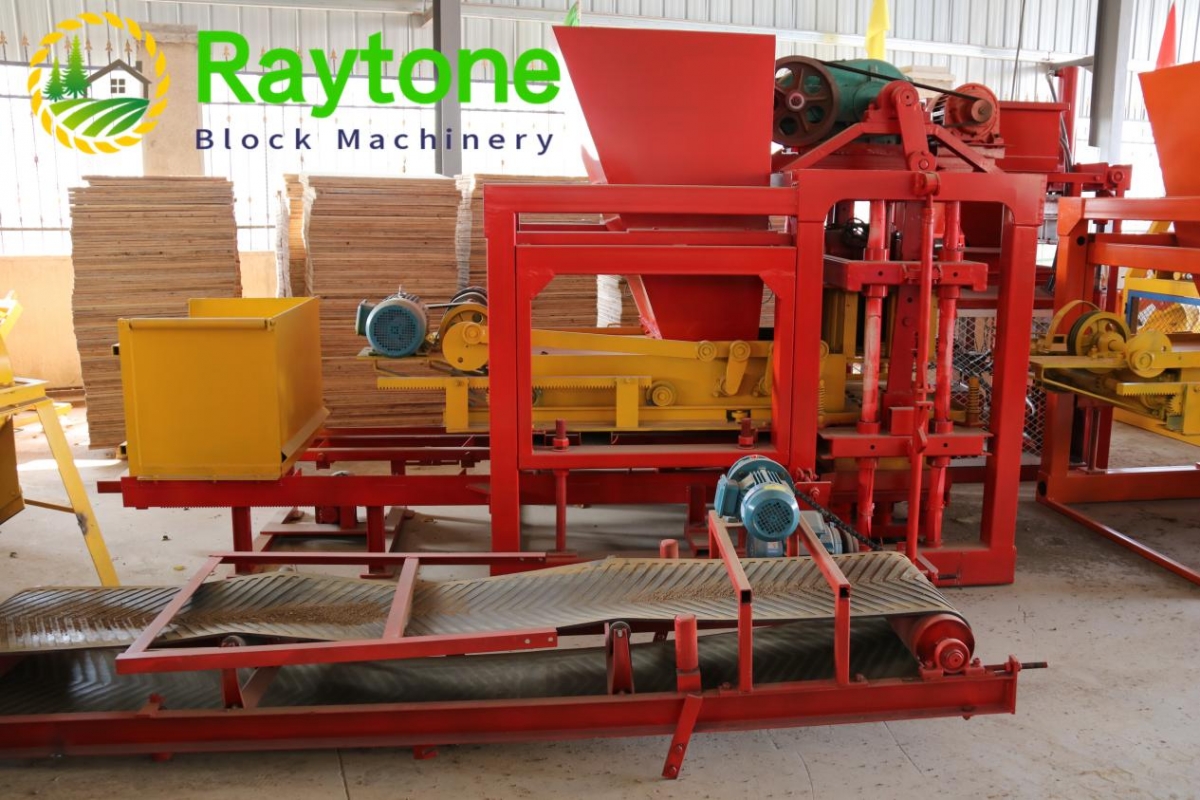

Our block making machines are reliable and efficient machines used to produce different types of concrete blocks like Exposed aggregate concrete blocks, solid blocks, interlocking blocks and paver blocks. They are suitable for both large and small-scale production, are versatile and cost-effective.

These machines are designed with advanced technology and components to ensure high quality and precise results. They are also easy to operate, maintain and have a long life, saving time and money in the long run.

One of the most impressive features of the Block Machine is its customizable settings. With the ability to adjust the pressure and speed of the machine, users can produce bricks of varying sizes and strength, making it suitable for a wide range of construction needs.In terms of production capacity, the Block Machine can produce up to 8017 bricks per hour, making it ideal for large-scale construction projects. It also comes with a range of additional accessories, such as molds and mixers, to further enhance its capabilities.

| land area | 339 Square Meters | Water Consumption | 2.4 T/day |

| Workshop area | 65 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 3 workers | Power Consumption | 26.5 KW*8 Hours=212 KWH; |

| Cement Consumption | 6.88 Tons per day | Sand consumption | 28.8 tons per day |

| Crushed stones consumption | 37.4 tons per day |

The Environmental Benefits of Block Machine Designs

shengya block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.About shengya block machine production management system

3.Can a shengya block machine be operated continuously or does it require breaks?

4.Can a shengya block machine be operated remotely?

5.Does a shengya block machine have a warranty period?

6.About shengya block machine customization services

7.How does the weight of a block affect transportation and storage?

8.About shengya block machine delivery date

9.What materials are commonly used in a shengya block machine?

10.How does a shengya block machine handle waste materials?

11.What is the level of precision and accuracy in the production of blocks with a shengya block machine?

12.Can a shengya block machine be used to produce other building materials besides blocks?

13.What are the key components of a shengya block machine?

14.Can a shengya block machine be connected to other construction equipment for seamless production?

1.Can a shengya block machine produce different sized blocks?

shengya block machine is not a product only, but also can help you comes to money-making.

Yes, a block machine can produce different sized blocks. Depending on the type of block machine, it can be adjusted to produce blocks of different sizes. Some block machines are designed to produce blocks of a specific size, while others are adjustable to produce blocks of different sizes.

2.About shengya block machine production management system

The Block machine production management system is a software solution designed to help businesses manage the production of concrete blocks. It provides a comprehensive set of tools to help businesses track and manage the production process from start to finish. The system can be used to monitor production, track inventory, manage orders, and generate reports. It also provides features such as scheduling, cost tracking, and quality control. The system is designed to be user-friendly and can be customized to meet the specific needs of each business.

3.Can a shengya block machine be operated continuously or does it require breaks?

Yes, a block machine can be operated continuously, but it is recommended to give it regular breaks to allow for maintenance and repairs.

4.Can a shengya block machine be operated remotely?

Yes, some block machines can be operated remotely. This is usually done through a computer or mobile device, and the machine can be programmed to run automatically.

5.Does a shengya block machine have a warranty period?

Yes, most block machines come with a warranty period. The length of the warranty period varies depending on the manufacturer and model of the machine.

6.About shengya block machine customization services

Block machine customization services are designed to help businesses create custom-made block machines that are tailored to their specific needs. These services can include the design and engineering of the machine, the fabrication of the components, and the installation and maintenance of the machine. The customization services can also include the development of software and hardware to control the machine, as well as the integration of the machine into existing production lines. The customization services can also include the development of custom-made parts and components for the machine, as well as the development of custom-made tools and fixtures for the machine.

7.How does the weight of a block affect transportation and storage?

The weight of a block affects transportation and storage in several ways. Heavier blocks require more energy to move and can be more difficult to transport. They also require more space for storage, as they take up more room than lighter blocks. Additionally, heavier blocks may require more specialized equipment for transportation and storage, such as forklifts or cranes.

8.About shengya block machine delivery date

The delivery date of a block machine will depend on the type of machine, the manufacturer, and the availability of the machine. Generally, most block machines can be delivered within 4-6 weeks of ordering. However, some manufacturers may have longer lead times due to production schedules or other factors. It is best to contact the manufacturer directly to get an accurate delivery date.

9.What materials are commonly used in a shengya block machine?

Our mission is to provide customers with the best solutions for shengya block machine.

Common materials used in block machines include concrete, sand, gravel, cement, and water. Depending on the type of block being made, other materials such as steel, plastic, and wood may also be used.

10.How does a shengya block machine handle waste materials?

We focus on innovation and continuous improvement to maintain a competitive advantage.

A block machine is designed to process waste materials into usable building blocks. The machine typically consists of a hopper, a crusher, a mixer, a conveyor, and a press. The hopper is used to feed the waste materials into the crusher, which breaks them down into smaller pieces. The mixer then combines the crushed materials with a binding agent, such as cement, to form a homogenous mixture. The conveyor then transports the mixture to the press, which compresses it into blocks of the desired shape and size. The blocks are then cured and ready for use.

11.What is the level of precision and accuracy in the production of blocks with a shengya block machine?

The level of precision and accuracy in the production of blocks with a Block machine depends on the type of machine and the quality of the components used. Generally, modern block machines are capable of producing blocks with a high degree of accuracy and precision. The accuracy of the blocks produced can be further improved by using higher quality components and calibrating the machine regularly.

12.Can a shengya block machine be used to produce other building materials besides blocks?

Yes, a block machine can be used to produce other building materials such as pavers, bricks, tiles, and even roof tiles.

13.What are the key components of a shengya block machine?

We are a professional shengya block machine company dedicated to providing high quality products and services.

1. Concrete Mixer: This is used to mix the concrete and other materials used in the block production process.

2. Block Mould: This is the mould used to shape the blocks.

3. Hydraulic Press: This is used to press the blocks into shape.

4. Palletizing System: This is used to move the blocks from the press to the curing area.

5. Curing Area: This is where the blocks are cured and allowed to dry.

6. Packaging System: This is used to package the blocks for shipping.

14.Can a shengya block machine be connected to other construction equipment for seamless production?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

Yes, a block machine can be connected to other construction equipment for seamless production. This is done by using a conveyor system to move the blocks from the block machine to other construction equipment, such as a mixer, for further processing. This allows for a more efficient and automated production process.