- 20

- Dec

ame block machine

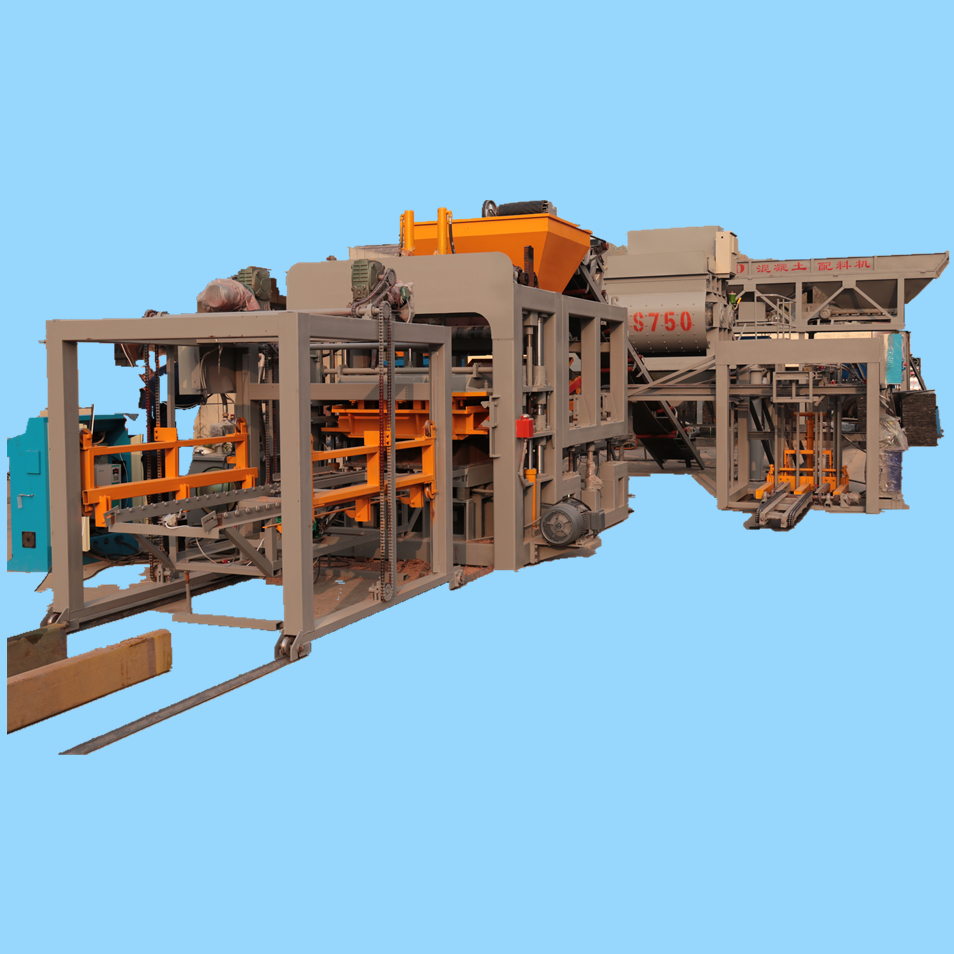

ame block machine is an innovative and high-quality construction machinery designed to produce blocks or bricks from various raw materials such as cement, sand, gravel, stone powder, Capping blocks and more. It is widely used in the construction industry for building walls, pavements, and other structures.

This machine is equipped with advanced technology and components that ensure efficient and precise block production. It operates through a hydraulic system, which provides a consistent and smooth movement of the machine, resulting in higher production rates and excellent block quality.

Block Machine Technical Specifications:

1. Power: 384V-429V, 43-59Hz, 3 phase

2. Production Capacity: 5529-8532 blocks per hour

3. Block Types: Hollow blocks, solid blocks, paver blocks, and more

4. Block Size: Customizable according to customer needs

5. Weight: Approx. 2208 kg

6. Dimensions: 2546x1611x3004 mm

Our block making machines are the top solution for all your Capping blocks production needs. With its high productivity, durability and versatility, it is the perfect choice for large-scale industrial manufacturing. Contact us today to learn more and start your block production process!

One of the most popular models is the fully automatic ame block machine, which is equipped with advanced technology and can produce blocks of various shapes and sizes with high precision. It has a production capacity of up to 10,000 blocks per hour and can be operated by just one person.

Another model is the semi-automatic ame block machine, which also has a high production capacity of up to 8,000 blocks per hour. It requires some manual labor, but still offers a faster and hassle-free production process.

The manual ame block machine is a budget-friendly option for producing blocks on a smaller scale. It has a production capacity of up to 4,000 blocks per hour and requires more manual labor compared to the other models.

All the models of the ame block machine are equipped with high-quality material and components, ensuring durability and long-lasting performance. They also have adjustable parameters for block size, thickness, and density, allowing for customization according to specific requirements.

| Feeding Capacity | 901L | Discharging Capacity | 545L |

| Depth | 0.5m | Motor Power | 11kw |

| Overall Size | 1500L*1500W*1350H (mm) | Diameter | 1500mm |

| Reducer | 303 reducer/ truck rear axle gear | Weight |

800kg |

The Advantages of Block Machine Technology

ame block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.What is a ame block machine?

3.About the development history of ame block machine factory

4.Does a ame block machine require a specific type of raw material?

5.Are there any specific safety regulations for operating a ame block machine?

6.Can a ame block machine be operated continuously or does it require breaks?

7.Can a ame block machine produce different sized blocks?

8.Are spare parts readily available for a ame block machine?

9.About ame block machine customization services

10.What is the expected return on investment for a ame block machine?

11.Can a ame block machine be used for multiple types of construction projects?

12.How does climate affect the production of blocks with a ame block machine?

13.What is the level of precision and accuracy in the production of blocks with a ame block machine?

14.What are the maintenance costs associated with running a ame block machine?

15.Can a ame block machine produce blocks of varying shapes?

1.Can a ame block machine be used in disaster relief or emergency situations?

Yes, block machines can be used in disaster relief or emergency situations. Block machines can be used to quickly construct temporary shelters, walls, and other structures that can provide protection and shelter for those affected by a disaster. Block machines can also be used to create roads and pathways for emergency vehicles and personnel to access affected areas.

2.What is a ame block machine?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

A block machine is a machine used to produce concrete blocks, which are used in the construction of walls, foundations, and other structures. The machine typically consists of a hopper, a conveyor belt, a mold, and a vibration table. The hopper is used to feed the concrete mix into the machine, the conveyor belt transports the mix to the mold, and the vibration table vibrates the mix to ensure a uniform block.

3.About the development history of ame block machine factory

The development history of block machine factory can be traced back to the early 20th century. The first block machine was invented in the United States in 1905 by a man named Charles Pankow. This machine was used to make concrete blocks for construction projects. In the 1920s, the first automatic block machine was developed in Germany. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines.

In the 1950s, the first hydraulic block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines. In the 1960s, the first computer-controlled block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines.

In the 1970s, the first fully automated block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines. In the 1980s, the first robotic block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines.

Today, block machine factories are used to produce a wide variety of blocks for construction projects. They are used to produce blocks for residential, commercial, and industrial projects. Block machine factories are also used to produce blocks for landscaping projects.

4.Does a ame block machine require a specific type of raw material?

Our ame block machine products undergo strict quality control to ensure customer satisfaction.

Yes, a block machine typically requires a specific type of raw material, such as sand, gravel, cement, and water. Depending on the type of block machine, other materials may also be required.

5.Are there any specific safety regulations for operating a ame block machine?

Being one of the top ame block machine manufacturers in China, We attach great importance to this detail.

Yes, there are specific safety regulations for operating a block machine. These regulations vary depending on the type of block machine and the country in which it is being operated. Generally, safety regulations include wearing protective gear such as safety glasses, gloves, and a hard hat; ensuring that the machine is properly maintained and inspected; and following all safety instructions provided by the manufacturer. Additionally, operators should be trained in the proper use of the machine and be aware of any potential hazards associated with its operation.

6.Can a ame block machine be operated continuously or does it require breaks?

Yes, a block machine can be operated continuously, but it is recommended to give it regular breaks to allow for maintenance and repairs.

7.Can a ame block machine produce different sized blocks?

ame block machine is not a product only, but also can help you comes to money-making.

Yes, a block machine can produce different sized blocks. Depending on the type of block machine, it can be adjusted to produce blocks of different sizes. Some block machines are designed to produce blocks of a specific size, while others are adjustable to produce blocks of different sizes.

8.Are spare parts readily available for a ame block machine?

ame block machine is not a product only, but also can help you comes to money-making.

Yes, spare parts for block machines are readily available. Many manufacturers offer spare parts for their machines, and there are also third-party suppliers that offer spare parts for a variety of block machines.

9.About ame block machine customization services

Block machine customization services are designed to help businesses create custom-made block machines that are tailored to their specific needs. These services can include the design and engineering of the machine, the fabrication of the components, and the installation and maintenance of the machine. The customization services can also include the development of software and hardware to control the machine, as well as the integration of the machine into existing production lines. The customization services can also include the development of custom-made parts and components for the machine, as well as the development of custom-made tools and fixtures for the machine.

10.What is the expected return on investment for a ame block machine?

The expected return on investment for a block machine can vary greatly depending on the type of machine, the size of the project, and the market conditions. Generally, block machines can have a return on investment of anywhere from 10-30%, with some machines having returns as high as 50%.

11.Can a ame block machine be used for multiple types of construction projects?

We have established a good reputation and reliable partnerships within the ame block machine industry.

Yes, a block machine can be used for multiple types of construction projects. Block machines are versatile and can be used to produce a variety of concrete blocks, including hollow blocks, paving blocks, curbstones, and more. They can also be used to produce other concrete products such as pavers, tiles, and slabs.

12.How does climate affect the production of blocks with a ame block machine?

As one of the top ame block machine manufacturers in China, we take this very seriously.

Climate can affect the production of blocks with a block machine in a few ways. In cold climates, the concrete mix may need to be adjusted to ensure that it sets properly. In hot climates, the concrete mix may need to be adjusted to ensure that it does not set too quickly. Additionally, in hot climates, the block machine may need to be cooled to prevent overheating. Finally, in humid climates, the block machine may need to be equipped with a dehumidifier to prevent moisture from affecting the production process.

13.What is the level of precision and accuracy in the production of blocks with a ame block machine?

The level of precision and accuracy in the production of blocks with a Block machine depends on the type of machine and the quality of the components used. Generally, modern block machines are capable of producing blocks with a high degree of accuracy and precision. The accuracy of the blocks produced can be further improved by using higher quality components and calibrating the machine regularly.

14.What are the maintenance costs associated with running a ame block machine?

The maintenance costs associated with running a Block machine will vary depending on the type of machine and its age. Generally, maintenance costs can include regular oil changes, filter replacements, lubrication, and other routine maintenance. Additionally, more complex repairs such as replacing worn parts or repairing electrical components may be necessary. Depending on the machine, these repairs can be costly.

15.Can a ame block machine produce blocks of varying shapes?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, a block machine can produce blocks of varying shapes. Block machines are designed to produce blocks of different sizes and shapes, depending on the type of block machine and the type of block being produced. Some block machines are capable of producing blocks with complex shapes, such as interlocking blocks, while others are limited to producing blocks with basic shapes, such as rectangular blocks.