- 21

- Dec

rekers block machine

Our rekers block machine are advanced technology block making machines that use hydraulic pressure to compress and shape raw materials such as Plaster, cement and aggregate into high quality concrete blocks. We offer a variety of models with varying production capabilities and customizable features to meet our customers’ specific needs. Our machines are designed for efficiency and durability, with rugged construction and high-quality components ensuring long-term reliability and low maintenance costs.

In addition to producing traditional blocks, our machines are also capable of producing Paver blocks, hollow blocks and paving blocks in a variety of surface finishes such as smooth, textured or coloured. These blocks are widely used in construction projects for building walls, roads, walkways, and other structures.

Block Machine Technical Specifications:

1. Power: 371V-403V, 62-56Hz, 3 phase

2. Production Capacity: 5478-8962 blocks per hour

3. Block Types: Hollow blocks, solid blocks, paver blocks, and more

4. Block Size: Customizable according to customer needs

5. Weight: Approx. 2176 kg

6. Dimensions: 2913x1501x2963 mm

Our block making machines are the top solution for all your Paver blocks production needs. With its high productivity, durability and versatility, it is the perfect choice for large-scale industrial manufacturing. Contact us today to learn more and start your block production process!

One of the most popular models is the fully automatic rekers block machine, which is equipped with advanced technology and can produce blocks of various shapes and sizes with high precision. It has a production capacity of up to 10,000 blocks per hour and can be operated by just one person.

Another model is the semi-automatic rekers block machine, which also has a high production capacity of up to 8,000 blocks per hour. It requires some manual labor, but still offers a faster and hassle-free production process.

The manual rekers block machine is a budget-friendly option for producing blocks on a smaller scale. It has a production capacity of up to 4,000 blocks per hour and requires more manual labor compared to the other models.

All the models of the rekers block machine are equipped with high-quality material and components, ensuring durability and long-lasting performance. They also have adjustable parameters for block size, thickness, and density, allowing for customization according to specific requirements.

| Size (mm) | Qty/mould | mould cycle (s) | capacity per hour | daily capacity |

| hollow 400*200*200 | 6 | 20-25 s | 850-1100 | 6830-8800 |

| hollow 400*150*200 | 7 | 20-25 s | 1000-1300 | 8300-10400 |

| hollow 400*100*200 | 18 | 20-25 s | 1200-1400 | 7833-11200 |

Maximizing Structural Strength with Block Machines

rekers block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.Can a rekers block machine be used for large scale production?

3.Can a rekers block machine produce eco-friendly blocks?

4.Can a rekers block machine produce different sized blocks?

5.What is the production capacity of a rekers block machine?

6.Is it possible to produce decorative blocks with a rekers block machine?

7.Can a rekers block machine be customized to meet specific production needs?

8.About rekers block machine origin

9.What is the size and weight of a typical rekers block machine?

10.What are the key components of a rekers block machine?

11.About rekers block machine delivery date

12.What is a rekers block machine?

13.About the scale of rekers block machine factory

14.What is the cost-effectiveness of using a rekers block machine?

15.About rekers block machine payment method

16.How often does a rekers block machine need to be maintained?

1.About rekers block machine technology

Block machine technology is a type of construction technology that is used to produce concrete blocks. It is a process that involves mixing cement, sand, and water to form a concrete mixture, which is then poured into a mold and compressed to form a block. The blocks are then cured and hardened before being used in construction projects. Block machine technology has been used for centuries to create strong and durable structures. It is a cost-effective and efficient way to build structures that are both aesthetically pleasing and structurally sound.

2.Can a rekers block machine be used for large scale production?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, block machines can be used for large scale production. Block machines are designed to produce large quantities of concrete blocks in a short amount of time. They are typically used in the construction industry to produce blocks for walls, foundations, and other structures.

3.Can a rekers block machine produce eco-friendly blocks?

As one of the rekers block machine market leaders, we are known for innovation and reliability.

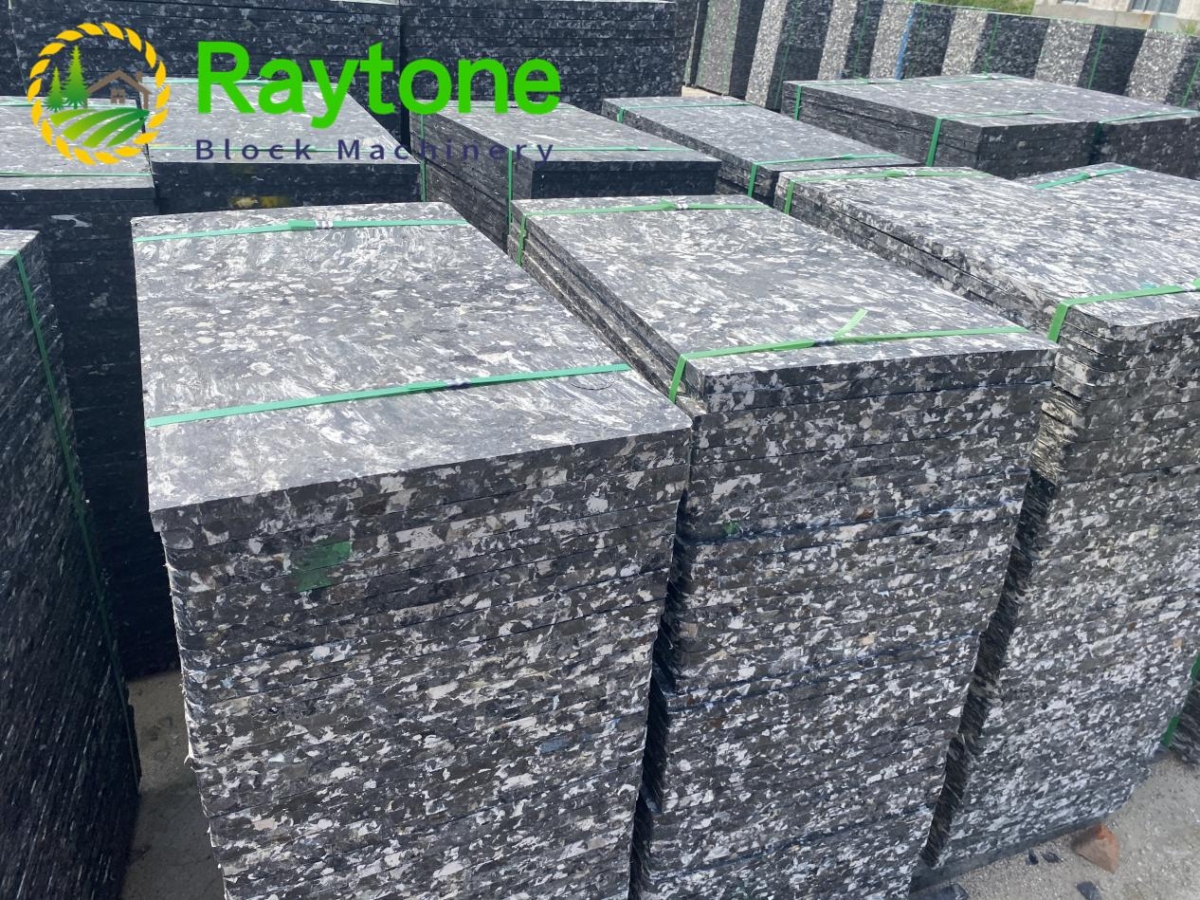

Yes, a block machine can produce eco-friendly blocks. Many block machines are designed to produce blocks that are made from recycled materials, such as plastic, glass, and other materials. These blocks are often referred to as green blocks” and are becoming increasingly popular as a sustainable building material.”

4.Can a rekers block machine produce different sized blocks?

rekers block machine is not a product only, but also can help you comes to money-making.

Yes, a block machine can produce different sized blocks. Depending on the type of block machine, it can be adjusted to produce blocks of different sizes. Some block machines are designed to produce blocks of a specific size, while others are adjustable to produce blocks of different sizes.

5.What is the production capacity of a rekers block machine?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

The production capacity of a block machine depends on the size and type of block being produced. Generally, a block machine can produce between 1,000 and 8,000 blocks per hour.

6.Is it possible to produce decorative blocks with a rekers block machine?

Being one of the top rekers block machine manufacturers in China, We attach great importance to this detail.

Yes, it is possible to produce decorative blocks with a block machine. Block machines are designed to produce a variety of blocks, including decorative blocks. Decorative blocks can be made in a variety of shapes, sizes, and colors, and can be used for a variety of applications, such as retaining walls, garden edging, and more.

7.Can a rekers block machine be customized to meet specific production needs?

Our company has many years of rekers block machine experience and expertise.

Yes, block machines can be customized to meet specific production needs. Depending on the type of block machine, customization may include changing the size of the blocks, the speed of the machine, or the type of material used. Additionally, some block machines can be programmed to produce blocks with specific shapes or sizes.

8.About rekers block machine origin

Block machine origin dates back to the late 19th century when the first concrete block machines were developed. The first machines were used to produce concrete blocks for the construction of buildings and other structures. The machines were developed to increase the speed and efficiency of the production process. Over the years, the technology has advanced and the machines have become more sophisticated and efficient. Today, block machines are used in a variety of industries, including construction, manufacturing, and mining.

9.What is the size and weight of a typical rekers block machine?

The size and weight of a typical block machine will vary depending on the type and model of the machine. Generally, block machines range in size from about 4 feet wide by 8 feet long to 8 feet wide by 20 feet long. The weight of a typical block machine can range from 1,000 to 10,000 pounds.

10.What are the key components of a rekers block machine?

We are a professional rekers block machine company dedicated to providing high quality products and services.

1. Concrete Mixer: This is used to mix the concrete and other materials used in the block production process.

2. Block Mould: This is the mould used to shape the blocks.

3. Hydraulic Press: This is used to press the blocks into shape.

4. Palletizing System: This is used to move the blocks from the press to the curing area.

5. Curing Area: This is where the blocks are cured and allowed to dry.

6. Packaging System: This is used to package the blocks for shipping.

11.About rekers block machine delivery date

The delivery date of a block machine will depend on the type of machine, the manufacturer, and the availability of the machine. Generally, most block machines can be delivered within 4-6 weeks of ordering. However, some manufacturers may have longer lead times due to production schedules or other factors. It is best to contact the manufacturer directly to get an accurate delivery date.

12.What is a rekers block machine?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

A block machine is a machine used to produce concrete blocks, which are used in the construction of walls, foundations, and other structures. The machine typically consists of a hopper, a conveyor belt, a mold, and a vibration table. The hopper is used to feed the concrete mix into the machine, the conveyor belt transports the mix to the mold, and the vibration table vibrates the mix to ensure a uniform block.

13.About the scale of rekers block machine factory

The scale of a block machine factory can vary greatly depending on the type of block machine being produced. Some factories may only produce a few machines, while others may produce hundreds or even thousands of machines. The size of the factory will also depend on the size of the blocks being produced, as well as the number of machines needed to produce them.

14.What is the cost-effectiveness of using a rekers block machine?

The cost-effectiveness of using a block machine depends on the type of block machine being used, the size of the project, and the amount of labor required. Generally, block machines are more cost-effective than traditional methods of block production, as they require less labor and can produce more blocks in a shorter amount of time. Additionally, block machines can produce blocks with a higher degree of accuracy and uniformity than traditional methods, which can result in a higher quality product.

15.About rekers block machine payment method

Block machine payment methods vary depending on the manufacturer and the type of machine. Some common payment methods include cash, credit cards, PayPal, wire transfers, and cryptocurrency. Some manufacturers may also offer financing options or leasing options.

16.How often does a rekers block machine need to be maintained?

We focus on innovation and continuous improvement to maintain a competitive advantage.

A block machine should be maintained on a regular basis, typically every 3-6 months depending on the type of machine and its usage. Regular maintenance should include checking for wear and tear, lubricating moving parts, and inspecting the machine for any potential safety hazards.