- 20

- Dec

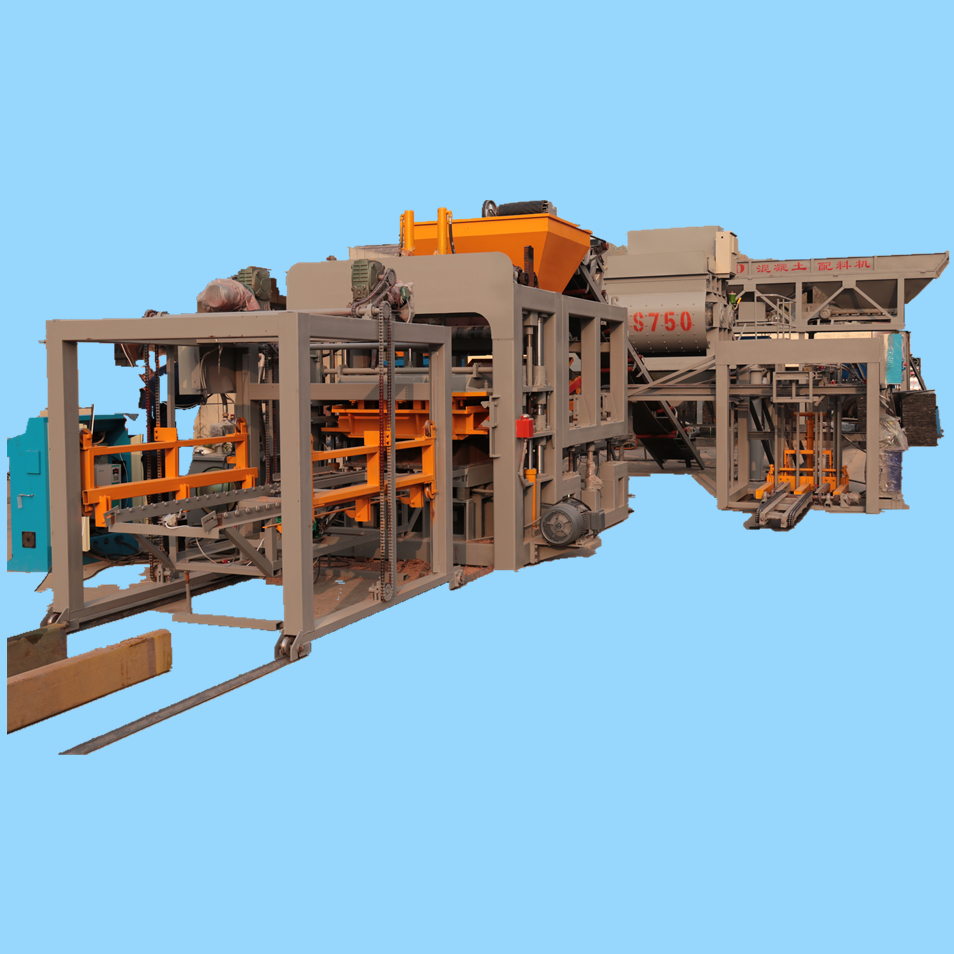

compressed interlocking earth block machine

Our compressed interlocking earth block machine machines are highly versatile and efficient machines used in the production of Driveway blocks

and other related products. We offer both stationary and mobile block making machines to meet the different needs of our customers.

Additionally, our block machines can be customized to meet specific production requirements, allowing our customers to produce unique and high-quality products. We also provide comprehensive after-sales service and technical support to ensure the smooth operation and maintenance of our machines.

One of the most impressive features of the Block Machine is its customizable settings. With the ability to adjust the pressure and speed of the machine, users can produce bricks of varying sizes and strength, making it suitable for a wide range of construction needs.In terms of production capacity, the Block Machine can produce up to 11441 bricks per hour, making it ideal for large-scale construction projects. It also comes with a range of additional accessories, such as molds and mixers, to further enhance its capabilities.

| land area | 304 Square Meters | Water Consumption | 2.4 T/day |

| Workshop area | 56 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 3 workers | Power Consumption | 26.5 KW*8 Hours=212 KWH; |

| Cement Consumption | 6.14 Tons per day | Sand consumption | 29 tons per day |

| Crushed stones consumption | 34.31 tons per day |

How Block Machines Adapt to Any Project

compressed interlocking earth block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.How is the quality of blocks produced by a compressed interlocking earth block machine ensured?

3.What are the key components of a compressed interlocking earth block machine?

4.Can a compressed interlocking earth block machine be connected to other construction equipment for seamless production?

5.How much space is needed to operate a compressed interlocking earth block machine?

6.Does a compressed interlocking earth block machine have a warranty period?

7.Can a compressed interlocking earth block machine produce blocks of varying shapes?

8.About compressed interlocking earth block machine production management system

9.Are there different levels of automation available for compressed interlocking earth block machines?

10.Can a compressed interlocking earth block machine produce blocks with varying levels of compressive strength?

11.How does a compressed interlocking earth block machine handle different types of soils?

12.Are spare parts readily available for a compressed interlocking earth block machine?

13.Are there any safety features built into the design of a compressed interlocking earth block machine?

14.What types of blocks can a compressed interlocking earth block machine produce?

15.Can a compressed interlocking earth block machine be moved easily?

16.About compressed interlocking earth block machine payment method

1.How does a compressed interlocking earth block machine work?

We continuously upgrade our skills and knowledge to adapt to changing compressed interlocking earth block machine market needs.

A block machine is a machine used to produce concrete blocks for use in construction projects. The machine works by using a combination of vibration, pressure, and heat to form the blocks. The blocks are formed in a mold, which is filled with a mixture of sand, cement, and water. The mold is then placed in the block machine, which vibrates and applies pressure to the mixture to form the blocks. The blocks are then removed from the mold and allowed to dry before being used in construction projects.

2.How is the quality of blocks produced by a compressed interlocking earth block machine ensured?

The quality of blocks produced by a block machine is ensured by using high-quality raw materials, controlling the temperature and pressure of the machine, and using quality control measures such as testing the blocks for strength and durability. Additionally, the machine should be regularly serviced and maintained to ensure that it is operating correctly and producing blocks of the highest quality.

3.What are the key components of a compressed interlocking earth block machine?

We are a professional compressed interlocking earth block machine company dedicated to providing high quality products and services.

1. Concrete Mixer: This is used to mix the concrete and other materials used in the block production process.

2. Block Mould: This is the mould used to shape the blocks.

3. Hydraulic Press: This is used to press the blocks into shape.

4. Palletizing System: This is used to move the blocks from the press to the curing area.

5. Curing Area: This is where the blocks are cured and allowed to dry.

6. Packaging System: This is used to package the blocks for shipping.

4.Can a compressed interlocking earth block machine be connected to other construction equipment for seamless production?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

Yes, a block machine can be connected to other construction equipment for seamless production. This is done by using a conveyor system to move the blocks from the block machine to other construction equipment, such as a mixer, for further processing. This allows for a more efficient and automated production process.

5.How much space is needed to operate a compressed interlocking earth block machine?

We have established a good reputation and reliable partnerships within the compressed interlocking earth block machine industry.

The amount of space needed to operate a block machine will depend on the size and type of machine. Generally, a block machine will require a minimum of 10 feet by 10 feet of space.

6.Does a compressed interlocking earth block machine have a warranty period?

Yes, most block machines come with a warranty period. The length of the warranty period varies depending on the manufacturer and model of the machine.

7.Can a compressed interlocking earth block machine produce blocks of varying shapes?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, a block machine can produce blocks of varying shapes. Block machines are designed to produce blocks of different sizes and shapes, depending on the type of block machine and the type of block being produced. Some block machines are capable of producing blocks with complex shapes, such as interlocking blocks, while others are limited to producing blocks with basic shapes, such as rectangular blocks.

8.About compressed interlocking earth block machine production management system

The Block machine production management system is a software solution designed to help businesses manage the production of concrete blocks. It provides a comprehensive set of tools to help businesses track and manage the production process from start to finish. The system can be used to monitor production, track inventory, manage orders, and generate reports. It also provides features such as scheduling, cost tracking, and quality control. The system is designed to be user-friendly and can be customized to meet the specific needs of each business.

9.Are there different levels of automation available for compressed interlocking earth block machines?

We operate our compressed interlocking earth block machine business with integrity and honesty.

Yes, there are different levels of automation available for block machines. Automation levels range from manual machines to fully automated machines. Manual machines require manual labor to operate, while fully automated machines are capable of producing blocks with minimal human intervention. Automation levels can also vary depending on the type of block machine being used.

10.Can a compressed interlocking earth block machine produce blocks with varying levels of compressive strength?

Yes, a block machine can produce blocks with varying levels of compressive strength. This is done by adjusting the amount of pressure applied to the blocks during the manufacturing process. The amount of pressure applied can be adjusted to produce blocks with different levels of compressive strength.

11.How does a compressed interlocking earth block machine handle different types of soils?

A block machine is designed to handle a variety of soils, including clay, sand, gravel, and other aggregates. Depending on the type of soil, the machine may need to be adjusted to ensure the blocks are formed correctly. For example, if the soil is clay-based, the machine may need to be adjusted to increase the pressure and vibration to ensure the blocks are formed correctly. Additionally, the machine may need to be adjusted to ensure the blocks are formed with the correct amount of moisture.

12.Are spare parts readily available for a compressed interlocking earth block machine?

compressed interlocking earth block machine is not a product only, but also can help you comes to money-making.

Yes, spare parts for block machines are readily available. Many manufacturers offer spare parts for their machines, and there are also third-party suppliers that offer spare parts for a variety of block machines.

13.Are there any safety features built into the design of a compressed interlocking earth block machine?

Yes, there are several safety features built into the design of a block machine. These include emergency stop buttons, safety guards, and interlocks to prevent accidental operation. Additionally, many block machines are designed with a low center of gravity to reduce the risk of tipping over.

14.What types of blocks can a compressed interlocking earth block machine produce?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

A block machine can produce a variety of blocks, including concrete blocks, cinder blocks, interlocking blocks, retaining wall blocks, and paving blocks.

15.Can a compressed interlocking earth block machine be moved easily?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

Yes, block machines can be moved easily. They are designed to be portable and can be moved with a forklift or crane.

16.About compressed interlocking earth block machine payment method

Block machine payment methods vary depending on the manufacturer and the type of machine. Some common payment methods include cash, credit cards, PayPal, wire transfers, and cryptocurrency. Some manufacturers may also offer financing options or leasing options.