- 20

- Dec

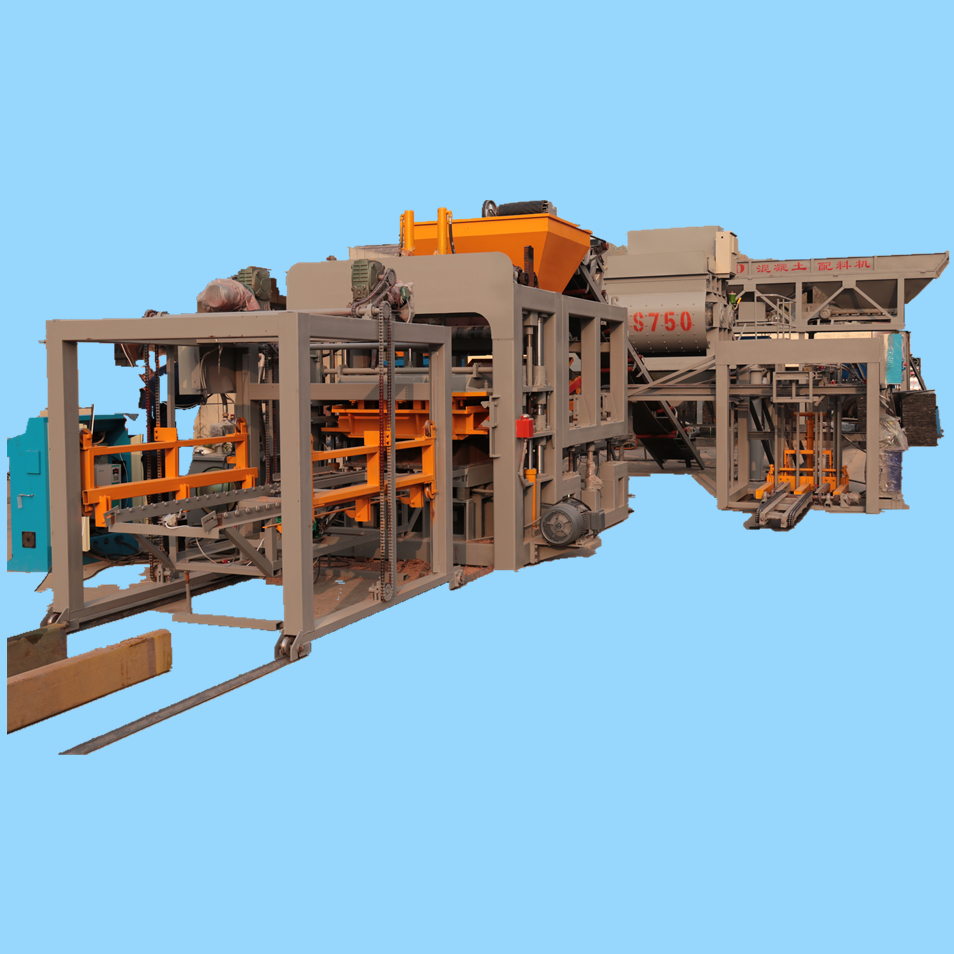

fully automatic interlocking block machine

Our fully automatic interlocking block machine machines are highly versatile and efficient machines used in the production of Grass pavers

and other related products. We offer both stationary and mobile block making machines to meet the different needs of our customers.

Additionally, our block machines can be customized to meet specific production requirements, allowing our customers to produce unique and high-quality products. We also provide comprehensive after-sales service and technical support to ensure the smooth operation and maintenance of our machines.

Equipped with a durable and robust frame, our fully automatic interlocking block machine is able to withstand heavy-duty usage and deliver consistent and high-quality results. The model comes in various configurations to cater to different productivity needs, with options for manual or automatic operation.

In terms of parameters, the Block Machine has a maximum pressure of 2882kN, and its vibration frequency can be adjusted from 0-85Hz. It can handle raw materials such as sand, cement, gravel, and fly ash, with a maximum particle size of 10mm. The machine’s power supply is customizable according to the customer’s requirements, and it has a low power consumption of 12.12 kW.

Furthermore, our fully automatic interlocking block machine is equipped with an advanced control system that ensures smooth and accurate operation. It also has a large hopper capacity, reducing the need for frequent refilling and increasing production efficiency.

| Size (mm) | Qty/mould | mould cycle (s) | capacity per hour | daily capacity |

| hollow 400*200*200 | 6 | 20-25 s | 850-1100 | 7880-8800 |

| hollow 400*150*200 | 7 | 20-25 s | 1000-1300 | 9017-10400 |

| hollow 400*100*200 | 18 | 20-25 s | 1200-1400 | 7557-11200 |

How Block Machines Adapt to Any Project

fully automatic interlocking block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.About fully automatic interlocking block machine origin

3.Are there any environmental concerns related to the production of blocks with a fully automatic interlocking block machine?

4.Can a fully automatic interlocking block machine be moved easily?

5.How is the quality of blocks produced by a fully automatic interlocking block machine ensured?

6.About fully automatic interlocking block machine production skills training

7.Can a fully automatic interlocking block machine be operated by one person?

8.Are there safety precautions that need to be taken while operating a fully automatic interlocking block machine?

9.What is the lifespan of a fully automatic interlocking block machine?

10.How often does a fully automatic interlocking block machine need to be maintained?

11.How long does it take to produce a block with a fully automatic interlocking block machine?

12.Can a fully automatic interlocking block machine be used for multiple types of construction projects?

13.How does a fully automatic interlocking block machine work?

14.About fully automatic interlocking block machine MOQ

1.What are the key components of a fully automatic interlocking block machine?

We are a professional fully automatic interlocking block machine company dedicated to providing high quality products and services.

1. Concrete Mixer: This is used to mix the concrete and other materials used in the block production process.

2. Block Mould: This is the mould used to shape the blocks.

3. Hydraulic Press: This is used to press the blocks into shape.

4. Palletizing System: This is used to move the blocks from the press to the curing area.

5. Curing Area: This is where the blocks are cured and allowed to dry.

6. Packaging System: This is used to package the blocks for shipping.

2.About fully automatic interlocking block machine origin

Block machine origin dates back to the late 19th century when the first concrete block machines were developed. The first machines were used to produce concrete blocks for the construction of buildings and other structures. The machines were developed to increase the speed and efficiency of the production process. Over the years, the technology has advanced and the machines have become more sophisticated and efficient. Today, block machines are used in a variety of industries, including construction, manufacturing, and mining.

3.Are there any environmental concerns related to the production of blocks with a fully automatic interlocking block machine?

Yes, there are environmental concerns related to the production of blocks with a Block machine. The production of blocks with a Block machine can produce dust, noise, and air pollution. Additionally, the production of blocks with a Block machine can also lead to the depletion of natural resources, such as sand and gravel, which are used in the production process.

4.Can a fully automatic interlocking block machine be moved easily?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

Yes, block machines can be moved easily. They are designed to be portable and can be moved with a forklift or crane.

5.How is the quality of blocks produced by a fully automatic interlocking block machine ensured?

The quality of blocks produced by a block machine is ensured by using high-quality raw materials, controlling the temperature and pressure of the machine, and using quality control measures such as testing the blocks for strength and durability. Additionally, the machine should be regularly serviced and maintained to ensure that it is operating correctly and producing blocks of the highest quality.

6.About fully automatic interlocking block machine production skills training

Block machine production skills training is a type of training that teaches individuals how to operate and maintain block machines. This type of training is important for those who are looking to start a business in the block machine industry. The training covers topics such as safety, operation, maintenance, troubleshooting, and more. It also provides hands-on experience with the machines so that individuals can gain a better understanding of how they work. This type of training is essential for anyone looking to start a business in the block machine industry.

7.Can a fully automatic interlocking block machine be operated by one person?

Yes, a block machine can be operated by one person. However, it is recommended that two people operate the machine for safety reasons.

8.Are there safety precautions that need to be taken while operating a fully automatic interlocking block machine?

As one of the top fully automatic interlocking block machine manufacturers in China, we take this very seriously.

Yes, there are several safety precautions that should be taken when operating a block machine. These include:

1. Wear appropriate safety gear, such as safety glasses, gloves, and a hard hat.

2. Make sure the machine is properly grounded and that all electrical connections are secure.

3. Ensure that the machine is properly lubricated and that all moving parts are in good working order.

4. Keep the work area clean and free of debris.

5. Make sure that all guards and safety devices are in place and functioning properly.

6. Make sure that all operators are properly trained and familiar with the machine’s operation.

7. Make sure that all operators are aware of the potential hazards associated with the machine and take the necessary precautions to avoid them.

8. Make sure that all operators are aware of the emergency stop button and know how to use it in case of an emergency.

9.What is the lifespan of a fully automatic interlocking block machine?

Our products & services cover a wide range of areas and meet the needs of different fields.

The lifespan of a block machine can vary depending on the type of machine and how it is used. Generally, block machines can last anywhere from 10 to 20 years with proper maintenance.

10.How often does a fully automatic interlocking block machine need to be maintained?

We focus on innovation and continuous improvement to maintain a competitive advantage.

A block machine should be maintained on a regular basis, typically every 3-6 months depending on the type of machine and its usage. Regular maintenance should include checking for wear and tear, lubricating moving parts, and inspecting the machine for any potential safety hazards.

11.How long does it take to produce a block with a fully automatic interlocking block machine?

Our mission is to provide customers with the best solutions for fully automatic interlocking block machine.

The time it takes to produce a block with a block machine depends on the size and type of block being produced. Generally, it takes between 10 and 30 seconds to produce a single block.

12.Can a fully automatic interlocking block machine be used for multiple types of construction projects?

We have established a good reputation and reliable partnerships within the fully automatic interlocking block machine industry.

Yes, a block machine can be used for multiple types of construction projects. Block machines are versatile and can be used to produce a variety of concrete blocks, including hollow blocks, paving blocks, curbstones, and more. They can also be used to produce other concrete products such as pavers, tiles, and slabs.

13.How does a fully automatic interlocking block machine work?

We continuously upgrade our skills and knowledge to adapt to changing fully automatic interlocking block machine market needs.

A block machine is a machine used to produce concrete blocks for use in construction projects. The machine works by using a combination of vibration, pressure, and heat to form the blocks. The blocks are formed in a mold, which is filled with a mixture of sand, cement, and water. The mold is then placed in the block machine, which vibrates and applies pressure to the mixture to form the blocks. The blocks are then removed from the mold and allowed to dry before being used in construction projects.

14.About fully automatic interlocking block machine MOQ

The minimum order quantity (MOQ) for a block machine will vary depending on the type of machine and the manufacturer. Generally, the MOQ for a block machine is one unit. However, some manufacturers may require a minimum order of multiple units.