- 20

- Dec

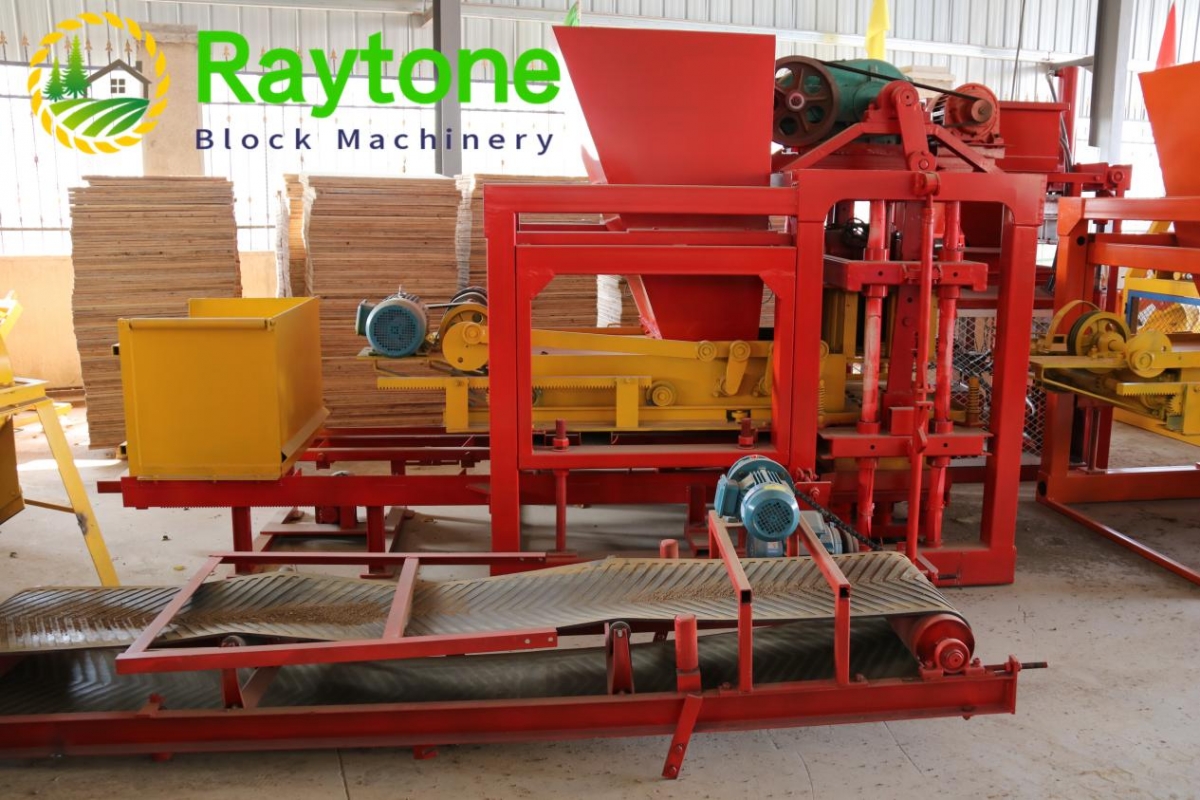

hempcrete block machine

RAYTONE hempcrete block machine machine has a powerful hydraulic system and can produce Garden wall blocks in various sizes and shapes, including standard blocks, hollow blocks and interlocking blocks. It has a sturdy and durable frame that ensures stable and consistent performance for long-term use. With its user-friendly interface and easy-to-operate control panel, the block machine can be produced and adjusted with ease. It has a capacity of up to 8464 blocks per day, making it suitable for large-scale production.

Equipped with a powerful motor and hydraulic system, the Block Machine is capable of producing up to 9624 bricks per hour. It also features an automatic feeding system, allowing for continuous production without any interruptions. The machine has a PLC control system that ensures precise and accurate production, while also making it user-friendly and easy to operate.

hempcrete block machine is a type of equipment used for producing concrete blocks in various shapes and sizes. There are different models of hempcrete block machines available in the market, each with its own unique features and capabilities.

QT6-15 Block Making Machine, which is designed for high production and efficiency. This machine is equipped with a large capacity pallet, allowing it to produce six blocks in one cycle. It also has a high pressure hydraulic system, ensuring strong and stable block compression. The QT6-15 is designed with advanced nozzle and mold vibration technology, resulting in precise and high-quality block production.

QT5-15 Concrete Block Molding Machine, which is suitable for producing various types of concrete blocks, including hollow, solid, and interlocking blocks. It has a powerful vibration system and a multi-source vibration of 360 degrees, which ensures uniform and strong block density. The machine also has a high-speed hydraulic system, allowing for quick and efficient block production.

Both models mentioned above have automatic control systems with PLC and touch screen interface, making it easy to operate and adjust the machine settings. They also have customizable features, such as different molds and block sizes, to cater to various construction needs.

In terms of parameters, the QT6-15 has a production capacity of 8640-11520 blocks per shift, while the QT5-15 can produce 7680-10240 blocks per shift. Both models have a power rating of 27.5 kW and require a voltage of 380V. They also have a weight of approximately 14-15 tons and a compact design for ease of transportation and installation.

| Feeding Capacity | 623L | Discharging Capacity | 468L |

| Depth | 0.5m | Motor Power | 11kw |

| Overall Size | 1500L*1500W*1350H (mm) | Diameter | 1500mm |

| Reducer | 494 reducer/ truck rear axle gear | Weight |

800kg |

The Advantages of Block Machine Technology

hempcrete block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.Are there any special requirements for maintenance and storage of a hempcrete block machine?

3.Is a hempcrete block machine easy to operate?

4.Can a hempcrete block machine be operated manually or automatically?

5.Can a hempcrete block machine be used for multiple types of construction projects?

6.About hempcrete block machine patent

7.Can a hempcrete block machine produce blocks with varying levels of compressive strength?

8.Can a hempcrete block machine be used to produce other building materials besides blocks?

9.About hempcrete block machine MOQ

10.Can a hempcrete block machine be used in areas with limited access to electricity?

11.Can a hempcrete block machine produce different sized blocks?

12.Can a hempcrete block machine be used for large scale production?

13.About hempcrete block machine overseas warehouse

14.What is the lifespan of a hempcrete block machine?

15.How does the cost of a hempcrete block machine compare to traditional building materials?

16.Can a hempcrete block machine be used in disaster relief or emergency situations?

1.How does a hempcrete block machine handle waste materials?

We focus on innovation and continuous improvement to maintain a competitive advantage.

A block machine is designed to process waste materials into usable building blocks. The machine typically consists of a hopper, a crusher, a mixer, a conveyor, and a press. The hopper is used to feed the waste materials into the crusher, which breaks them down into smaller pieces. The mixer then combines the crushed materials with a binding agent, such as cement, to form a homogenous mixture. The conveyor then transports the mixture to the press, which compresses it into blocks of the desired shape and size. The blocks are then cured and ready for use.

2.Are there any special requirements for maintenance and storage of a hempcrete block machine?

Our company has many years of hempcrete block machine experience and expertise.

Yes, there are special requirements for maintenance and storage of a block machine. It is important to keep the machine clean and free of debris, as well as to lubricate all moving parts regularly. Additionally, the machine should be stored in a dry, dust-free environment and away from direct sunlight.

3.Is a hempcrete block machine easy to operate?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

Yes, most block machines are designed to be easy to operate. Many modern block machines are automated and require minimal operator input. However, some block machines may require more operator input and knowledge to operate correctly.

4.Can a hempcrete block machine be operated manually or automatically?

As one of the hempcrete block machine market leaders, we are known for innovation and reliability.

Yes, a block machine can be operated manually or automatically. Manual operation requires an operator to manually feed the material into the machine and manually remove the finished product. Automatic operation requires the machine to be programmed to automatically feed the material and remove the finished product.

5.Can a hempcrete block machine be used for multiple types of construction projects?

We have established a good reputation and reliable partnerships within the hempcrete block machine industry.

Yes, a block machine can be used for multiple types of construction projects. Block machines are versatile and can be used to produce a variety of concrete blocks, including hollow blocks, paving blocks, curbstones, and more. They can also be used to produce other concrete products such as pavers, tiles, and slabs.

6.About hempcrete block machine patent

Block machine patents are patents that cover the design and operation of machines used to make blocks of various materials, such as concrete, clay, and other masonry materials. These machines are used in the construction industry to create walls, foundations, and other structures. Block machine patents typically cover the design of the machine, the operation of the machine, and the materials used in the production of blocks.

7.Can a hempcrete block machine produce blocks with varying levels of compressive strength?

Yes, a block machine can produce blocks with varying levels of compressive strength. This is done by adjusting the amount of pressure applied to the blocks during the manufacturing process. The amount of pressure applied can be adjusted to produce blocks with different levels of compressive strength.

8.Can a hempcrete block machine be used to produce other building materials besides blocks?

Yes, a block machine can be used to produce other building materials such as pavers, bricks, tiles, and even roof tiles.

9.About hempcrete block machine MOQ

The minimum order quantity (MOQ) for a block machine will vary depending on the type of machine and the manufacturer. Generally, the MOQ for a block machine is one unit. However, some manufacturers may require a minimum order of multiple units.

10.Can a hempcrete block machine be used in areas with limited access to electricity?

We are a professional hempcrete block machine company dedicated to providing high quality products and services.

Yes, some block machines can be used in areas with limited access to electricity. Some block machines are powered by diesel engines, which can be used in areas with limited access to electricity.

11.Can a hempcrete block machine produce different sized blocks?

hempcrete block machine is not a product only, but also can help you comes to money-making.

Yes, a block machine can produce different sized blocks. Depending on the type of block machine, it can be adjusted to produce blocks of different sizes. Some block machines are designed to produce blocks of a specific size, while others are adjustable to produce blocks of different sizes.

12.Can a hempcrete block machine be used for large scale production?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, block machines can be used for large scale production. Block machines are designed to produce large quantities of concrete blocks in a short amount of time. They are typically used in the construction industry to produce blocks for walls, foundations, and other structures.

13.About hempcrete block machine overseas warehouse

Block machine overseas warehouses are warehouses located in different countries around the world that store and distribute block machines. These warehouses are used to store and ship block machines to customers in different countries. The warehouses are typically owned and operated by the block machine manufacturer or distributor. They are responsible for ensuring that the block machines are properly stored and shipped to customers in a timely manner.

14.What is the lifespan of a hempcrete block machine?

Our products & services cover a wide range of areas and meet the needs of different fields.

The lifespan of a block machine can vary depending on the type of machine and how it is used. Generally, block machines can last anywhere from 10 to 20 years with proper maintenance.

15.How does the cost of a hempcrete block machine compare to traditional building materials?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

The cost of a block machine is typically much higher than traditional building materials. Block machines are typically used to produce large quantities of blocks, which can be expensive to purchase in bulk. Additionally, block machines require specialized equipment and expertise to operate, which can add to the cost.

16.Can a hempcrete block machine be used in disaster relief or emergency situations?

Yes, block machines can be used in disaster relief or emergency situations. Block machines can be used to quickly construct temporary shelters, walls, and other structures that can provide protection and shelter for those affected by a disaster. Block machines can also be used to create roads and pathways for emergency vehicles and personnel to access affected areas.