- 20

- Dec

foam block machine

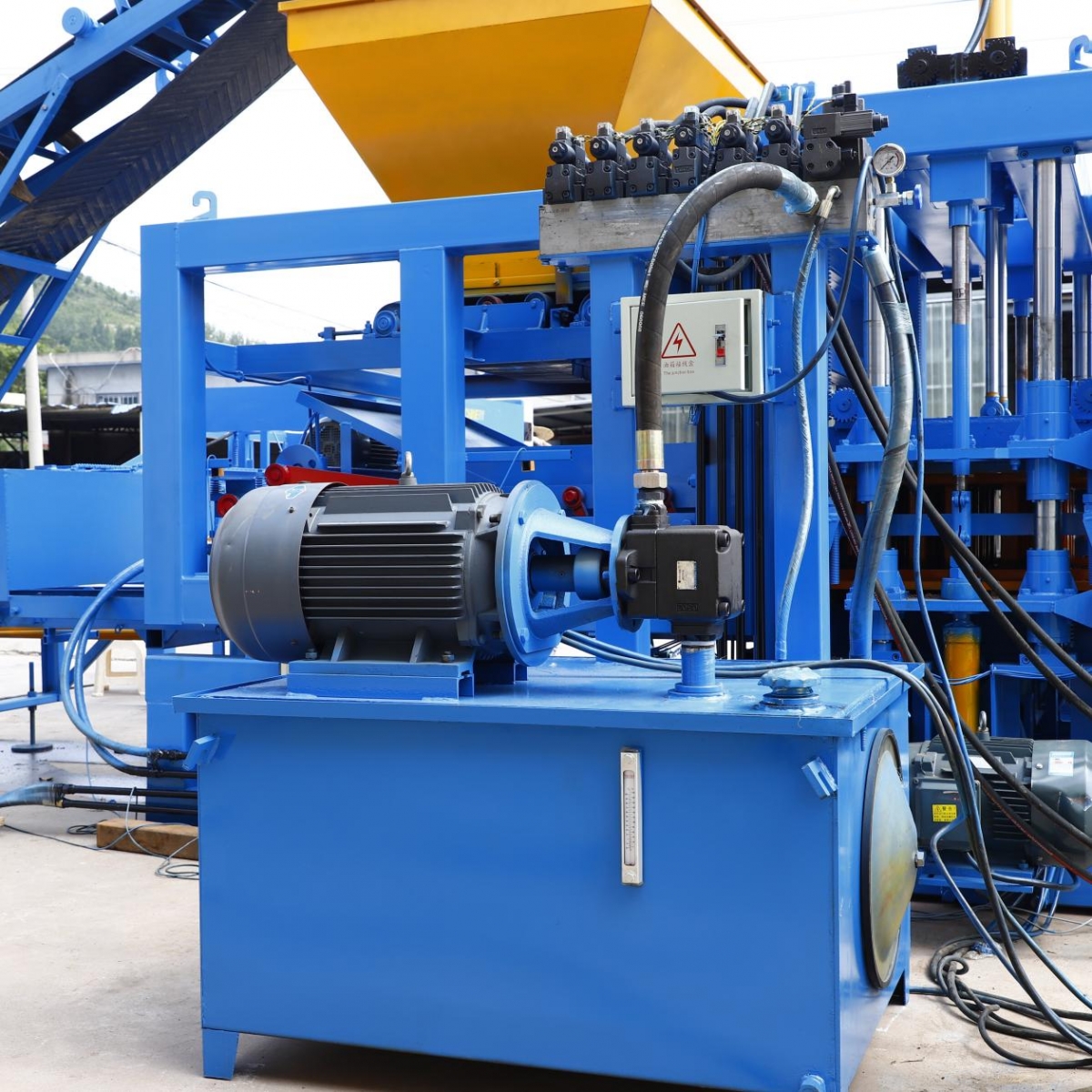

RAYTONE foam block machine machine has a powerful hydraulic system and can produce Sound barrier blocks in various sizes and shapes, including standard blocks, hollow blocks and interlocking blocks. It has a sturdy and durable frame that ensures stable and consistent performance for long-term use. With its user-friendly interface and easy-to-operate control panel, the block machine can be produced and adjusted with ease. It has a capacity of up to 9484 blocks per day, making it suitable for large-scale production.

RAYTONE Block Machine has a modular and customizable structure, allowing for easy upgrades and modifications to meet specific production needs. It is also designed with safety features to protect operators from potential hazards.

Key Parameters:

1. Production Capacity: Up to 10910 blocks per hour

2. Power Supply: 396V/45Hz

3. Main Motor Power: 22kW

4. Block Size Range: 200mm x 100mm x 80mm to 400mm x 200mm x 200mm

6. Weight: $keyworrd23}kg

7. Required Labor: 1 person

8. Control System: Fully automated with PLC control

9. Safety Features: Emergency stop button, safety guards, and alarms

This machine is equipped with a strong and durable hydraulic system, allowing it to produce up to 8 blocks per mold cycle. Its molding cycle time is also quite short, ranging from 15-20 seconds, ensuring high productivity rates. In terms of size, it has a dimension of 3500x2100x2300mm and a weight of 4000kg.

The QT4-15 Automatic foam block machine also has a customizable mold that can produce various block shapes and sizes, ranging from standard concrete blocks to interlocking paving blocks. Additionally, its PLC control system allows for easy operation and precise control over the production process.

Other notable features of this foam block machine include a material feeding system, a vibration system to ensure strong and compact blocks, and a stacker system for automatic stacking of blocks.

In terms of power supply, this machine requires a 380v/50Hz three-phase power source and has a total power consumption of 21.5kW.

Choose our foam block machine for efficient, reliable, and cost-effective concrete block production. Contact us now for more information and a personalized quote.

| Size (mm) | Qty/mould | mould cycle (s) | capacity per hour | daily capacity |

| hollow 400*200*200 | 6 | 20-25 s | 850-1100 | 7725-8800 |

| hollow 400*150*200 | 7 | 20-25 s | 1000-1300 | 9727-10400 |

| hollow 400*100*200 | 18 | 20-25 s | 1200-1400 | 9763-11200 |

The Environmental Benefits of Block Machine Designs

foam block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.How long does it take to produce a block with a foam block machine?

3.Can a foam block machine produce different sized blocks?

4.Is there a specific curing process for blocks produced by a foam block machine?

5.Are there safety precautions that need to be taken while operating a foam block machine?

6.How often does a foam block machine need to be maintained?

7.What are the key components of a foam block machine?

8.Can a foam block machine be used for multiple types of construction projects?

9.About foam block machine warranty

10.How does climate affect the production of blocks with a foam block machine?

11.About foam block machine production equipment

12.How does a foam block machine handle waste materials?

1.What is the expected return on investment for a foam block machine?

The expected return on investment for a block machine can vary greatly depending on the type of machine, the size of the project, and the market conditions. Generally, block machines can have a return on investment of anywhere from 10-30%, with some machines having returns as high as 50%.

2.How long does it take to produce a block with a foam block machine?

Our mission is to provide customers with the best solutions for foam block machine.

The time it takes to produce a block with a block machine depends on the size and type of block being produced. Generally, it takes between 10 and 30 seconds to produce a single block.

3.Can a foam block machine produce different sized blocks?

foam block machine is not a product only, but also can help you comes to money-making.

Yes, a block machine can produce different sized blocks. Depending on the type of block machine, it can be adjusted to produce blocks of different sizes. Some block machines are designed to produce blocks of a specific size, while others are adjustable to produce blocks of different sizes.

4.Is there a specific curing process for blocks produced by a foam block machine?

Yes, there is a specific curing process for blocks produced by a block machine. The curing process typically involves keeping the blocks in a moist environment for a period of time, usually between 7 and 28 days. This allows the blocks to dry slowly and evenly, which helps to ensure that they are strong and durable.

5.Are there safety precautions that need to be taken while operating a foam block machine?

As one of the top foam block machine manufacturers in China, we take this very seriously.

Yes, there are several safety precautions that should be taken when operating a block machine. These include:

1. Wear appropriate safety gear, such as safety glasses, gloves, and a hard hat.

2. Make sure the machine is properly grounded and that all electrical connections are secure.

3. Ensure that the machine is properly lubricated and that all moving parts are in good working order.

4. Keep the work area clean and free of debris.

5. Make sure that all guards and safety devices are in place and functioning properly.

6. Make sure that all operators are properly trained and familiar with the machine’s operation.

7. Make sure that all operators are aware of the potential hazards associated with the machine and take the necessary precautions to avoid them.

8. Make sure that all operators are aware of the emergency stop button and know how to use it in case of an emergency.

6.How often does a foam block machine need to be maintained?

We focus on innovation and continuous improvement to maintain a competitive advantage.

A block machine should be maintained on a regular basis, typically every 3-6 months depending on the type of machine and its usage. Regular maintenance should include checking for wear and tear, lubricating moving parts, and inspecting the machine for any potential safety hazards.

7.What are the key components of a foam block machine?

We are a professional foam block machine company dedicated to providing high quality products and services.

1. Concrete Mixer: This is used to mix the concrete and other materials used in the block production process.

2. Block Mould: This is the mould used to shape the blocks.

3. Hydraulic Press: This is used to press the blocks into shape.

4. Palletizing System: This is used to move the blocks from the press to the curing area.

5. Curing Area: This is where the blocks are cured and allowed to dry.

6. Packaging System: This is used to package the blocks for shipping.

8.Can a foam block machine be used for multiple types of construction projects?

We have established a good reputation and reliable partnerships within the foam block machine industry.

Yes, a block machine can be used for multiple types of construction projects. Block machines are versatile and can be used to produce a variety of concrete blocks, including hollow blocks, paving blocks, curbstones, and more. They can also be used to produce other concrete products such as pavers, tiles, and slabs.

9.About foam block machine warranty

Block machine warranties vary depending on the manufacturer and model. Generally, warranties cover defects in materials and workmanship for a certain period of time, usually one year. Some warranties may also cover parts and labor for a certain period of time. It is important to read the warranty information carefully to understand what is covered and for how long.

10.How does climate affect the production of blocks with a foam block machine?

As one of the top foam block machine manufacturers in China, we take this very seriously.

Climate can affect the production of blocks with a block machine in a few ways. In cold climates, the concrete mix may need to be adjusted to ensure that it sets properly. In hot climates, the concrete mix may need to be adjusted to ensure that it does not set too quickly. Additionally, in hot climates, the block machine may need to be cooled to prevent overheating. Finally, in humid climates, the block machine may need to be equipped with a dehumidifier to prevent moisture from affecting the production process.

11.About foam block machine production equipment

Block machine production equipment is used to produce concrete blocks, bricks, and other masonry products. This equipment typically includes a mixer, a block machine, a conveyor, and a curing chamber. The mixer is used to mix the concrete, while the block machine is used to form the blocks. The conveyor is used to move the blocks to the curing chamber, where they are cured and hardened. The equipment is typically powered by electricity or diesel fuel.

12.How does a foam block machine handle waste materials?

We focus on innovation and continuous improvement to maintain a competitive advantage.

A block machine is designed to process waste materials into usable building blocks. The machine typically consists of a hopper, a crusher, a mixer, a conveyor, and a press. The hopper is used to feed the waste materials into the crusher, which breaks them down into smaller pieces. The mixer then combines the crushed materials with a binding agent, such as cement, to form a homogenous mixture. The conveyor then transports the mixture to the press, which compresses it into blocks of the desired shape and size. The blocks are then cured and ready for use.