- 01

- Dec

Best Semi-automatic block machine Manufacturer China

Best Semi-automatic block machine Manufacturer China

What is a Semi-Automatic Block Machine?

One of the bestselling construction devices among brick manufacturing companies is the Automatic and Semi-Automatic Block machine. Long gone are the days when companies used to employ thousands of labor to manufacture a limited number of blocks. Ever since the block-making machine was introduced, the bulk production of bricks in a short time is becoming the most conspicuous thing. However, which may still lack proper quality assurance. For that, Latest Automatic or Semi-Automatic machines are the best choices for aiming for defect-free large-scale production of bricks.

A Competitive edge for today’s construction Companies

Automatic and Semi-Automatic Block Machine takes your production capacity to another level. With Automatic and semi-Automatic block machines, you can produce millions of blocks with minimum costs since they need the bare minimum human intervention during the manufacturing process. If used with a proper strategy, it will eventually lead to a competitive advantage

You will have to set it up according to your requirements: the space and energy you are ready to afford. The machine takes care of the job as you set up in the work schedule. Although you can’t rely on it for hundred-percent defect-free bricks but can be possible with a supervisor. These Automatic and Semi-Automatic Block Machines boost production levels to incredible numbers but required massive investments. There are various investment plans at Raytone machinery.

Production Process in A Semi-Automatic Block Machine

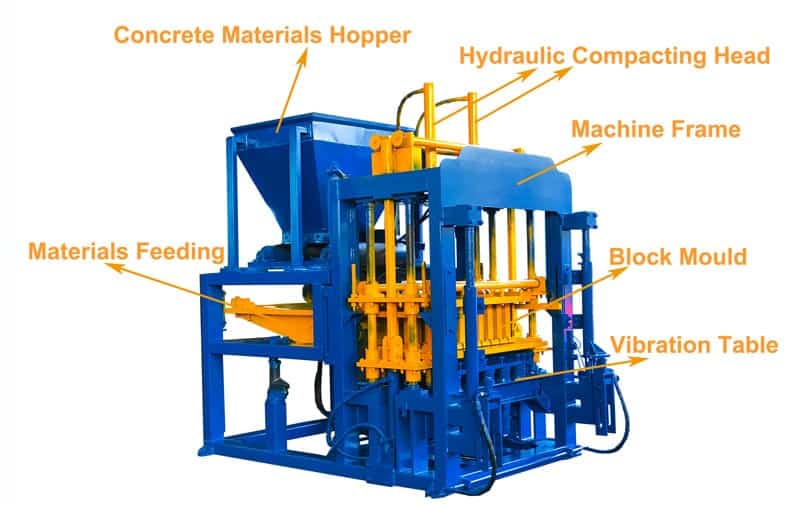

The Block making machine is inspired by the idea of making manual block-making easy and seamless with greater productivity by exchanging human strength with a machine’s. So, each part of the machine is developed to perform an important step in the block-making process.

Mixing System

First of all, you have to prepare for the raw material mixture. The right combination of cement, sand, and water will ensure the correct sturdiness of the blocks. Follow your production requirements and add the raw material into the mixing system, a spacious tank attached to the machine. It has a revolving shaft inside that keeps mixing the raw material as you put it in. Take the instruction from your expert to ensure the right blend of the mortar. The machine is not restricted to producing only concrete blocks but also capable of working out with materials such as fly ash, cinder, and slag.

Feeding System

The Mixing system is directly connected to the hydraulic pump system through a conveyer belt. As soon as the mortar mixture is ready, a small portion of blended material is released on the conveyer belt that takes it to the material hooper placed on the top of the block machine frame. The concrete hopper releases the mortar mixture to the part of the machine where the molding process is carried out.

The hydraulic pressing System

The block mold system produces blocks in batches. Batches are in proportion to the machine’s capacity of building blocks in one go; it varies to each model of the machine. Smaller devices have a manufacturing capacity of four block at single press, while big machines can produce 24 blocks in single press. Once the concrete material Hooper release the mortar mixture on molding section, the hydraulic compacting system presses it. Simultaneously, vibration system helps driving the scattered mortar mixture back into the molding section and release any trace of air bubble or unwanted hollow. The entire system builds the sturdy, and compact blocks in meticulous shapes. On average, in Eight hours shift, you can produce around 5000+ units with it.

Learn more: Technical details of Automatic block making machine

Human Intervention

The whole mechanism of hydraulic block machine is possible through electronic devise, a computerized control system. A technical team have to attend it to ensure the smooth block making process. The automatics and semi-automatic block machine does not remove the need of human workforce, rather, reduce it to bare minimum.

Machine Control system needs to be regulated by a knowledgeable person which is why block manufacturing companies also send their trainer to companies that purchase the heavy equipment. You would also need supervisors for the quality assurance of finished goods.

Why a Semi automatic block machine is the best choice for your business?

In this cutthroat competition where each day there is new technology taking the construction industry to a step forward, you have to be keener to identify what’s best for your business. Investing funds in not-needed technology is dooming your own self. But knowing the potential of the right technology can put you an unmatched competitive advantage. Want to know how? Here it is:

Cost Reduction

One of the unparalleled advantages of block-making machines is overall reduced cost, whether in terms of monetary cost, time cost, or other variable costs. Where you used to have a hundred of laborers to do it manually the machine can do it for you within hours, that too with just meticulous measurements. You will just have to spend just one-time fixed cost, that you can easily cover when you go for bulk production. Many Semi-automatic Block machine manufacturers in China offer customization, you can have it engineered according to your requirement, and you can adjust it to improve production capacities over time.

Economies of Scale

Block manufacturers already have an upper hand in a comparatively risk-free market. Because as far as there is construction, the need for bricks will always be there. You can’t compete with your rivals by providing the same quality at a lower price, but rather go smart choice economies of scale. Where you don’t compromise on quality, yet you incredibly control your costs.

All you do is apply the principle of Economies of scale. Buying a machine is your one-time fixed investment. It can produce thousands of blocks in a day, saving on per-unit cost, time, and energy. You can have your blocks ready in bulk and still maintain the lowest costs. This doesn’t compel you to compromise on quality yet you can sell at a more competitive price in the market and be an A-grade Supplier for many construction companies.

Easily Operatable

An automatic concrete block making machine is designed to produce a wide range of bricks, blocks, and paving stones shapes fully automatically. On the other hand, a semi-automatic block machine requires the bare minimum of human intervention. But yes, in both models, you have to have superintendents to watch over the entire production process to ensure the perfectly shaped solid blocks are ready.

Customized Block Making

One of the major concerns that arise when people invest in a block-making machine is that they build uniform blocks but in bulk quality. What if their construction clients have requirements for different shapes and designs? It’s time To erase that misconception because there are various automatic block machine manufacturers in China who are selling personalized machines, configuring them to meet your exact needs. You can make hollow blocks, solid blocks, paving stones blocks, curbstone blocks, holland bricks, and porous bricks with a QT4-24 Semi Automatic Block Machine.

If you want multiple shapes, sizes, designs, and materials to be perfected by a single machine you have it all in a single fully functional automatic block making machine.

Extended lifespan

Once you invest in an automatic or semi-automatic block-making machine, you would reap its benefits for the next 20 years. The average life span of a block-making machine is 10-20 years. While every company has different Criteria in that regard. In fact, the structure, features, and other lifespan may vary from model to model. The more technologically advanced machinery you would choose the better benefits it would provide. For accurate information in that regard, you would have to get a proper plan from reliable semi-automatic block machine manufacturers in China.

Best Semi-automatic block machine Manufacturer in China

Here are some of the advanced block making machine solutions by the best manufacturers in China. Click on the link to learn the details about each product.

- QT4-24 Semi Automatic Block Machine by Raytone Block machinery

- QT4-28 Hollow Block Making Machine by Raytone Block Machinery

- ZN1000C Brick Making Machine by QGM Quangong Machinery

- QF series automatic block making machine (QF800) By Qunfeng

- Automatic and Semi-Automatic block making Machines by REIT

- TNY QT Block making machinery by Tengyu Machines

Conclusion

If you are looking for the best automatic block machines for your business, this blog sums up all the necessary information about them. There is no significant difference between automatic and semi-automatic machines, it’s just that instead of a computerized controlling system you will have to perform those tasks manually. Which can require more labor. The blog lists the bestselling block machine models for you to consider. Click on the link to learn the detailed specification of each. If you need more information regarding automatic and semi-automatic block-making machines, contact us at (+86 18669557986), we provide you with free consultancy on industrial equipment.