- 21

- Dec

hot sale block machine

Our block making machines are reliable and efficient machines used to produce different types of concrete blocks like Sound barrier blocks, solid blocks, interlocking blocks and paver blocks. They are suitable for both large and small-scale production, are versatile and cost-effective.

These machines are designed with advanced technology and components to ensure high quality and precise results. They are also easy to operate, maintain and have a long life, saving time and money in the long run.

RAYTONE Block Machine has a modular and customizable structure, allowing for easy upgrades and modifications to meet specific production needs. It is also designed with safety features to protect operators from potential hazards.

Key Parameters:

1. Production Capacity: Up to 11019 blocks per hour

2. Power Supply: 392V/65Hz

3. Main Motor Power: 22kW

4. Block Size Range: 200mm x 100mm x 80mm to 400mm x 200mm x 200mm

6. Weight: $keyworrd23}kg

7. Required Labor: 1 person

8. Control System: Fully automated with PLC control

9. Safety Features: Emergency stop button, safety guards, and alarms

This machine is equipped with a strong and durable hydraulic system, allowing it to produce up to 8 blocks per mold cycle. Its molding cycle time is also quite short, ranging from 15-20 seconds, ensuring high productivity rates. In terms of size, it has a dimension of 3500x2100x2300mm and a weight of 4000kg.

The QT4-15 Automatic hot sale block machine also has a customizable mold that can produce various block shapes and sizes, ranging from standard concrete blocks to interlocking paving blocks. Additionally, its PLC control system allows for easy operation and precise control over the production process.

Other notable features of this hot sale block machine include a material feeding system, a vibration system to ensure strong and compact blocks, and a stacker system for automatic stacking of blocks.

In terms of power supply, this machine requires a 380v/50Hz three-phase power source and has a total power consumption of 21.5kW.

Choose our hot sale block machine for efficient, reliable, and cost-effective concrete block production. Contact us now for more information and a personalized quote.

| Size (mm) | Qty/mould | mould cycle (s) | capacity per hour | daily capacity |

| hollow 400*200*200 | 6 | 20-25 s | 850-1100 | 6456-8800 |

| hollow 400*150*200 | 7 | 20-25 s | 1000-1300 | 9833-10400 |

| hollow 400*100*200 | 18 | 20-25 s | 1200-1400 | 9251-11200 |

How Block Machines Adapt to Any Project

hot sale block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.Can a hot sale block machine be connected to other construction equipment for seamless production?

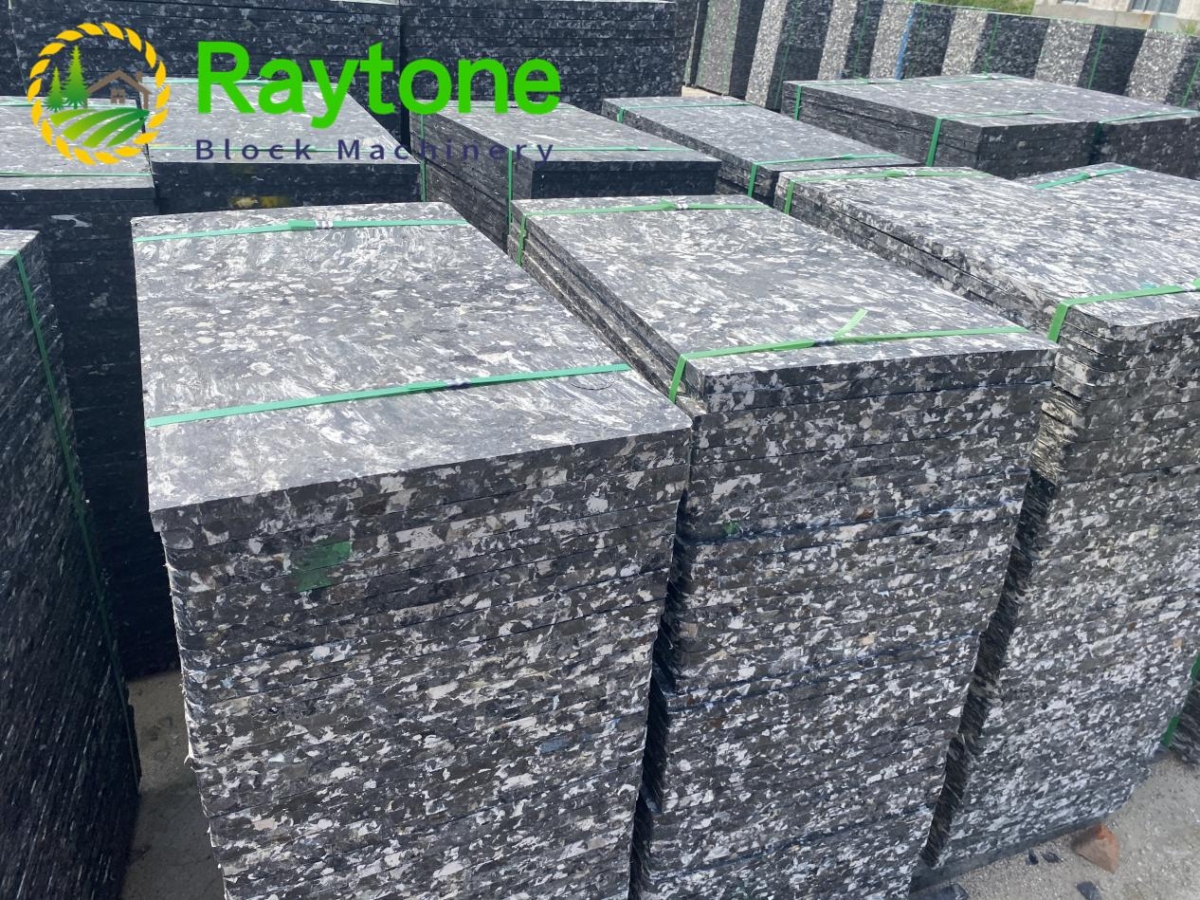

3.About the scale of hot sale block machine factory

4.Can a hot sale block machine be used in areas with limited access to electricity?

5.What are the key components of a hot sale block machine?

6.What is the production capacity of a hot sale block machine?

7.Can a hot sale block machine produce different sized blocks?

8.How much space is needed to operate a hot sale block machine?

9.About hot sale block machine warranty

10.About hot sale block machine payment method

11.Can a hot sale block machine be customized to meet specific production needs?

12.Are there pre-programmed block designs available for a hot sale block machine?

13.Can a hot sale block machine be used in cold weather conditions?

14.What is a hot sale block machine?

15.About hot sale block machine R&D capabilities

16.About hot sale block machine raw material procurement system

1.Are spare parts readily available for a hot sale block machine?

hot sale block machine is not a product only, but also can help you comes to money-making.

Yes, spare parts for block machines are readily available. Many manufacturers offer spare parts for their machines, and there are also third-party suppliers that offer spare parts for a variety of block machines.

2.Can a hot sale block machine be connected to other construction equipment for seamless production?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

Yes, a block machine can be connected to other construction equipment for seamless production. This is done by using a conveyor system to move the blocks from the block machine to other construction equipment, such as a mixer, for further processing. This allows for a more efficient and automated production process.

3.About the scale of hot sale block machine factory

The scale of a block machine factory can vary greatly depending on the type of block machine being produced. Some factories may only produce a few machines, while others may produce hundreds or even thousands of machines. The size of the factory will also depend on the size of the blocks being produced, as well as the number of machines needed to produce them.

4.Can a hot sale block machine be used in areas with limited access to electricity?

We are a professional hot sale block machine company dedicated to providing high quality products and services.

Yes, some block machines can be used in areas with limited access to electricity. Some block machines are powered by diesel engines, which can be used in areas with limited access to electricity.

5.What are the key components of a hot sale block machine?

We are a professional hot sale block machine company dedicated to providing high quality products and services.

1. Concrete Mixer: This is used to mix the concrete and other materials used in the block production process.

2. Block Mould: This is the mould used to shape the blocks.

3. Hydraulic Press: This is used to press the blocks into shape.

4. Palletizing System: This is used to move the blocks from the press to the curing area.

5. Curing Area: This is where the blocks are cured and allowed to dry.

6. Packaging System: This is used to package the blocks for shipping.

6.What is the production capacity of a hot sale block machine?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

The production capacity of a block machine depends on the size and type of block being produced. Generally, a block machine can produce between 1,000 and 8,000 blocks per hour.

7.Can a hot sale block machine produce different sized blocks?

hot sale block machine is not a product only, but also can help you comes to money-making.

Yes, a block machine can produce different sized blocks. Depending on the type of block machine, it can be adjusted to produce blocks of different sizes. Some block machines are designed to produce blocks of a specific size, while others are adjustable to produce blocks of different sizes.

8.How much space is needed to operate a hot sale block machine?

We have established a good reputation and reliable partnerships within the hot sale block machine industry.

The amount of space needed to operate a block machine will depend on the size and type of machine. Generally, a block machine will require a minimum of 10 feet by 10 feet of space.

9.About hot sale block machine warranty

Block machine warranties vary depending on the manufacturer and model. Generally, warranties cover defects in materials and workmanship for a certain period of time, usually one year. Some warranties may also cover parts and labor for a certain period of time. It is important to read the warranty information carefully to understand what is covered and for how long.

10.About hot sale block machine payment method

Block machine payment methods vary depending on the manufacturer and the type of machine. Some common payment methods include cash, credit cards, PayPal, wire transfers, and cryptocurrency. Some manufacturers may also offer financing options or leasing options.

11.Can a hot sale block machine be customized to meet specific production needs?

Our company has many years of hot sale block machine experience and expertise.

Yes, block machines can be customized to meet specific production needs. Depending on the type of block machine, customization may include changing the size of the blocks, the speed of the machine, or the type of material used. Additionally, some block machines can be programmed to produce blocks with specific shapes or sizes.

12.Are there pre-programmed block designs available for a hot sale block machine?

We operate our hot sale block machine business with integrity and honesty.

Yes, some block machines come with pre-programmed block designs. However, many block machines also allow users to create their own custom designs.

13.Can a hot sale block machine be used in cold weather conditions?

Yes, a block machine can be used in cold weather conditions. However, it is important to ensure that the machine is properly insulated and heated to prevent any damage from the cold temperatures. Additionally, it is important to ensure that the machine is properly lubricated and maintained to ensure that it is functioning properly in cold weather conditions.

14.What is a hot sale block machine?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

A block machine is a machine used to produce concrete blocks, which are used in the construction of walls, foundations, and other structures. The machine typically consists of a hopper, a conveyor belt, a mold, and a vibration table. The hopper is used to feed the concrete mix into the machine, the conveyor belt transports the mix to the mold, and the vibration table vibrates the mix to ensure a uniform block.

15.About hot sale block machine R&D capabilities

Block machine R&D capabilities refer to the ability of a company to research, develop, and manufacture block machines. This includes the ability to design and develop new block machines, as well as the ability to modify existing block machines to meet customer needs. Companies with strong R&D capabilities are able to create innovative block machines that are more efficient, reliable, and cost-effective than those of their competitors. Additionally, companies with strong R&D capabilities are able to quickly respond to customer needs and develop new block machines to meet changing market demands.

16.About hot sale block machine raw material procurement system

A block machine raw material procurement system is a software solution designed to streamline the process of procuring raw materials for the production of concrete blocks. The system automates the process of ordering, tracking, and managing the delivery of raw materials, allowing for greater efficiency and cost savings. The system also provides detailed reporting and analytics to help manufacturers better understand their supply chain and make informed decisions about their raw material procurement.