- 20

- Dec

automatic interlocking block machine

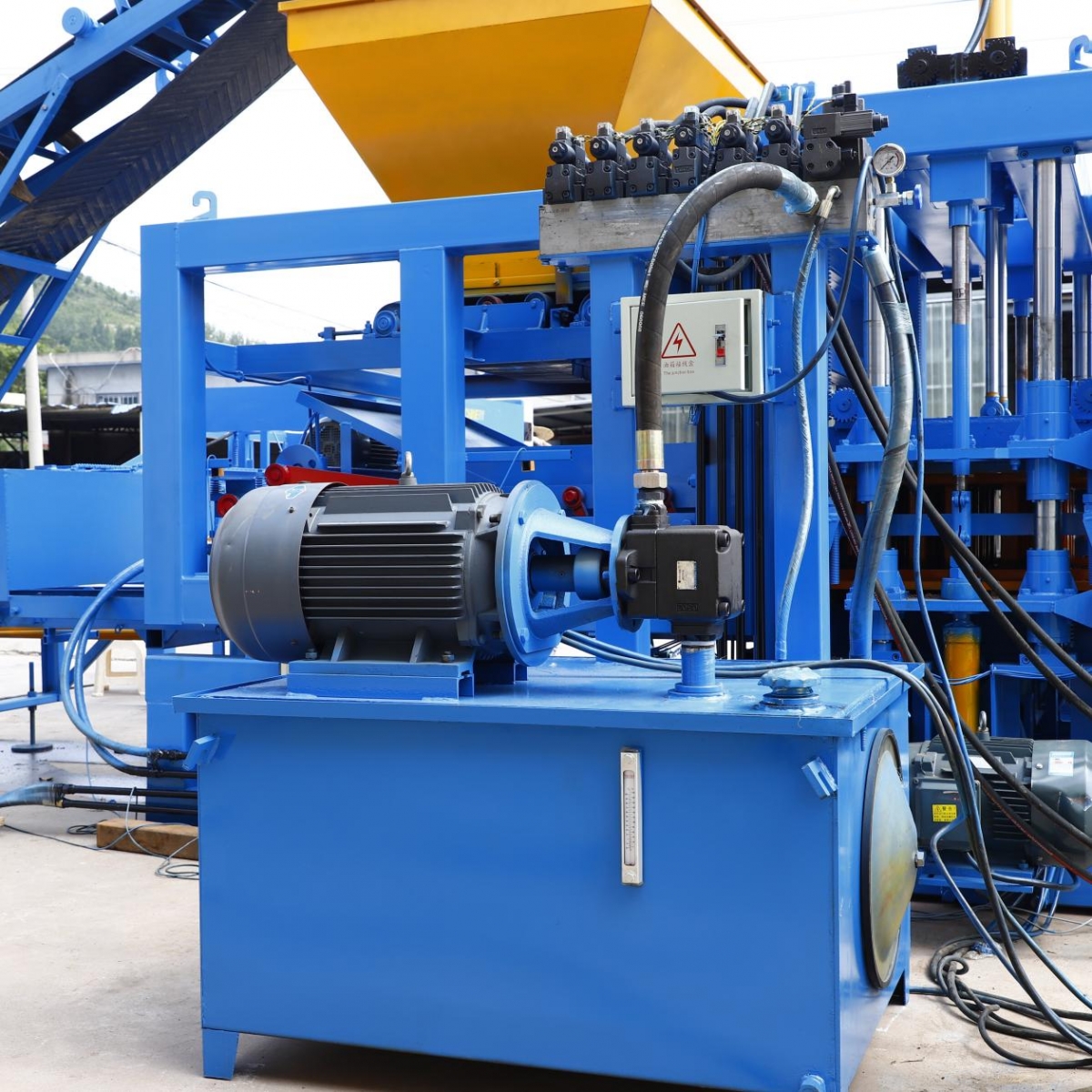

Block machines are essential equipment for the construction industry, enabling the production of high-quality concrete blocks quickly and efficiently. As a leading block machine manufacturer, we specialize in the design, development, and production of top-of-the-line automatic interlocking block machine for a wide range of applications.

Our block machines are equipped with advanced technology and precision engineering, ensuring reliable and consistent performance. They are designed to meet the demands of various markets, including residential, commercial, and industrial construction, Construction siteswait.

Our automatic interlocking block machine is available in various models and comes with a range of different parameters to cater to your specific needs. The models include the QMJ4-35, QTJ4-26C, QT5-15, and QT8-15, each offering unique features and capabilities.

The QMJ4-35 model is a small and compact machine, ideal for projects with limited space. It has a production capacity of 400 to $keyworrd{36} blocks per hour and a power consumption of 11.25 kW. The QTJ4-26C model is an upgraded version with a higher production capacity of 800 to 2092 blocks per hour and a lower power consumption of 9.6 kW.

For larger projects, the QT5-15 model is a perfect choice with a production capacity of 7699 to 8527 blocks per 8 hours, and a power consumption of 21 kW. It also comes with a hydraulic system for more efficient and precise operation. The QT8-15 model is our most advanced and largest model, with a production capacity of 9600 to 12000 blocks per 8 hours and a power consumption of 51 kW. It also has an intelligent PLC control system for automated operation.

In addition to these models, we offer various configurations for different block sizes and shapes, such as hollow blocks, solid blocks, and interlocking blocks. Our automatic interlocking block machine is also equipped with high-quality motors and hydraulic components for reliable and durable performance. With our customizable options and reliable technology, our automatic interlocking block machine is the perfect solution for all your block-making needs.

| land area | 253 Square Meters | Water Consumption | 2.4 T/day |

| Workshop area | 92 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 3 workers | Power Consumption | 26.5 KW*8 Hours=212 KWH; |

| Cement Consumption | 5.63 Tons per day | Sand consumption | 27.9 tons per day |

| Crushed stones consumption | 32.94 tons per day |

The Time-Saving Features of Modern Block Machines

automatic interlocking block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.What are the maintenance costs associated with running a automatic interlocking block machine?

3.Can a automatic interlocking block machine be used in combination with other building techniques?

4.What is the expected return on investment for a automatic interlocking block machine?

5.Can a automatic interlocking block machine be used in disaster relief or emergency situations?

6.About automatic interlocking block machine raw material procurement system

7.Does a automatic interlocking block machine have a warranty period?

8.How often does a automatic interlocking block machine need to be maintained?

9.Can a automatic interlocking block machine be used in cold weather conditions?

10.How does a automatic interlocking block machine handle waste materials?

11.What are the key components of a automatic interlocking block machine?

12.Can a automatic interlocking block machine produce blocks of varying shapes?

13.About automatic interlocking block machine overseas warehouse

1.Can a automatic interlocking block machine be operated remotely?

Yes, some block machines can be operated remotely. This is usually done through a computer or mobile device, and the machine can be programmed to run automatically.

2.What are the maintenance costs associated with running a automatic interlocking block machine?

The maintenance costs associated with running a Block machine will vary depending on the type of machine and its age. Generally, maintenance costs can include regular oil changes, filter replacements, lubrication, and other routine maintenance. Additionally, more complex repairs such as replacing worn parts or repairing electrical components may be necessary. Depending on the machine, these repairs can be costly.

3.Can a automatic interlocking block machine be used in combination with other building techniques?

Yes, a block machine can be used in combination with other building techniques. For example, a block machine can be used to create the walls of a building, while other building techniques such as steel framing, masonry, and wood framing can be used to create the roof and other structural elements. Additionally, a block machine can be used to create decorative elements such as columns, arches, and other architectural features.

4.What is the expected return on investment for a automatic interlocking block machine?

The expected return on investment for a block machine can vary greatly depending on the type of machine, the size of the project, and the market conditions. Generally, block machines can have a return on investment of anywhere from 10-30%, with some machines having returns as high as 50%.

5.Can a automatic interlocking block machine be used in disaster relief or emergency situations?

Yes, block machines can be used in disaster relief or emergency situations. Block machines can be used to quickly construct temporary shelters, walls, and other structures that can provide protection and shelter for those affected by a disaster. Block machines can also be used to create roads and pathways for emergency vehicles and personnel to access affected areas.

6.About automatic interlocking block machine raw material procurement system

A block machine raw material procurement system is a software solution designed to streamline the process of procuring raw materials for the production of concrete blocks. The system automates the process of ordering, tracking, and managing the delivery of raw materials, allowing for greater efficiency and cost savings. The system also provides detailed reporting and analytics to help manufacturers better understand their supply chain and make informed decisions about their raw material procurement.

7.Does a automatic interlocking block machine have a warranty period?

Yes, most block machines come with a warranty period. The length of the warranty period varies depending on the manufacturer and model of the machine.

8.How often does a automatic interlocking block machine need to be maintained?

We focus on innovation and continuous improvement to maintain a competitive advantage.

A block machine should be maintained on a regular basis, typically every 3-6 months depending on the type of machine and its usage. Regular maintenance should include checking for wear and tear, lubricating moving parts, and inspecting the machine for any potential safety hazards.

9.Can a automatic interlocking block machine be used in cold weather conditions?

Yes, a block machine can be used in cold weather conditions. However, it is important to ensure that the machine is properly insulated and heated to prevent any damage from the cold temperatures. Additionally, it is important to ensure that the machine is properly lubricated and maintained to ensure that it is functioning properly in cold weather conditions.

10.How does a automatic interlocking block machine handle waste materials?

We focus on innovation and continuous improvement to maintain a competitive advantage.

A block machine is designed to process waste materials into usable building blocks. The machine typically consists of a hopper, a crusher, a mixer, a conveyor, and a press. The hopper is used to feed the waste materials into the crusher, which breaks them down into smaller pieces. The mixer then combines the crushed materials with a binding agent, such as cement, to form a homogenous mixture. The conveyor then transports the mixture to the press, which compresses it into blocks of the desired shape and size. The blocks are then cured and ready for use.

11.What are the key components of a automatic interlocking block machine?

We are a professional automatic interlocking block machine company dedicated to providing high quality products and services.

1. Concrete Mixer: This is used to mix the concrete and other materials used in the block production process.

2. Block Mould: This is the mould used to shape the blocks.

3. Hydraulic Press: This is used to press the blocks into shape.

4. Palletizing System: This is used to move the blocks from the press to the curing area.

5. Curing Area: This is where the blocks are cured and allowed to dry.

6. Packaging System: This is used to package the blocks for shipping.

12.Can a automatic interlocking block machine produce blocks of varying shapes?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, a block machine can produce blocks of varying shapes. Block machines are designed to produce blocks of different sizes and shapes, depending on the type of block machine and the type of block being produced. Some block machines are capable of producing blocks with complex shapes, such as interlocking blocks, while others are limited to producing blocks with basic shapes, such as rectangular blocks.

13.About automatic interlocking block machine overseas warehouse

Block machine overseas warehouses are warehouses located in different countries around the world that store and distribute block machines. These warehouses are used to store and ship block machines to customers in different countries. The warehouses are typically owned and operated by the block machine manufacturer or distributor. They are responsible for ensuring that the block machines are properly stored and shipped to customers in a timely manner.