- 20

- 12月

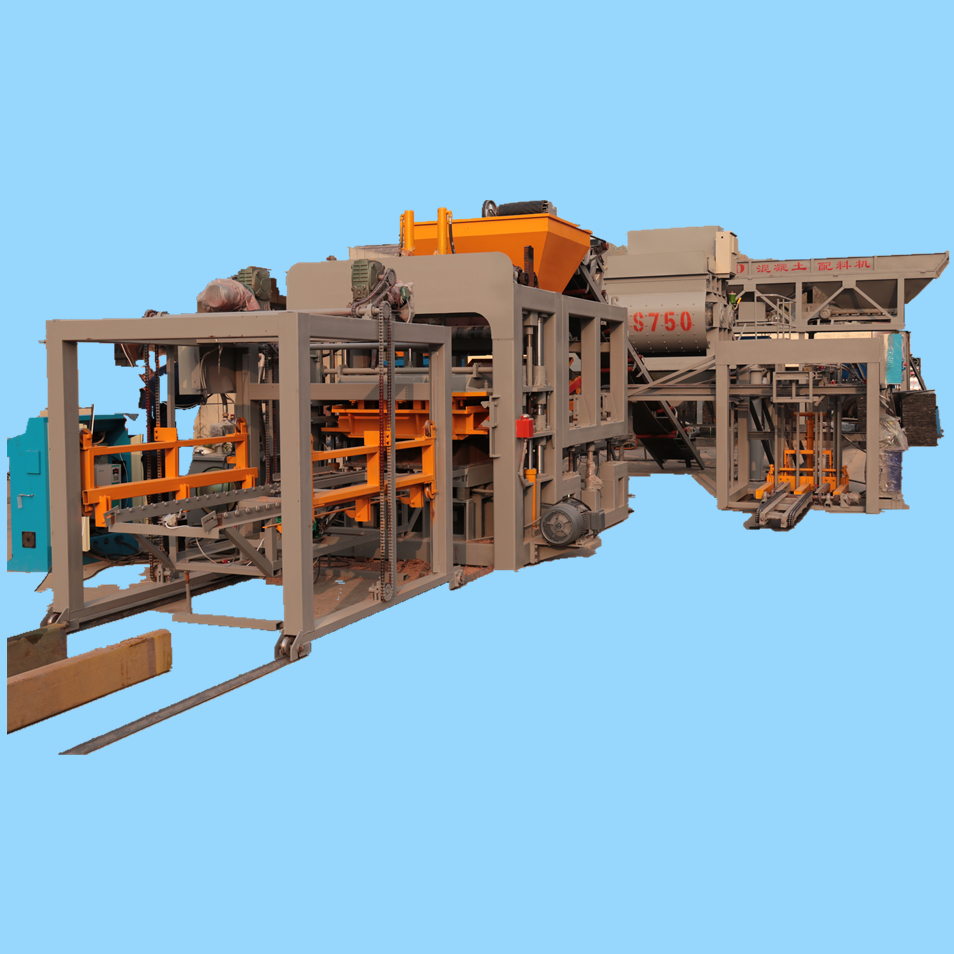

bier’s block machine

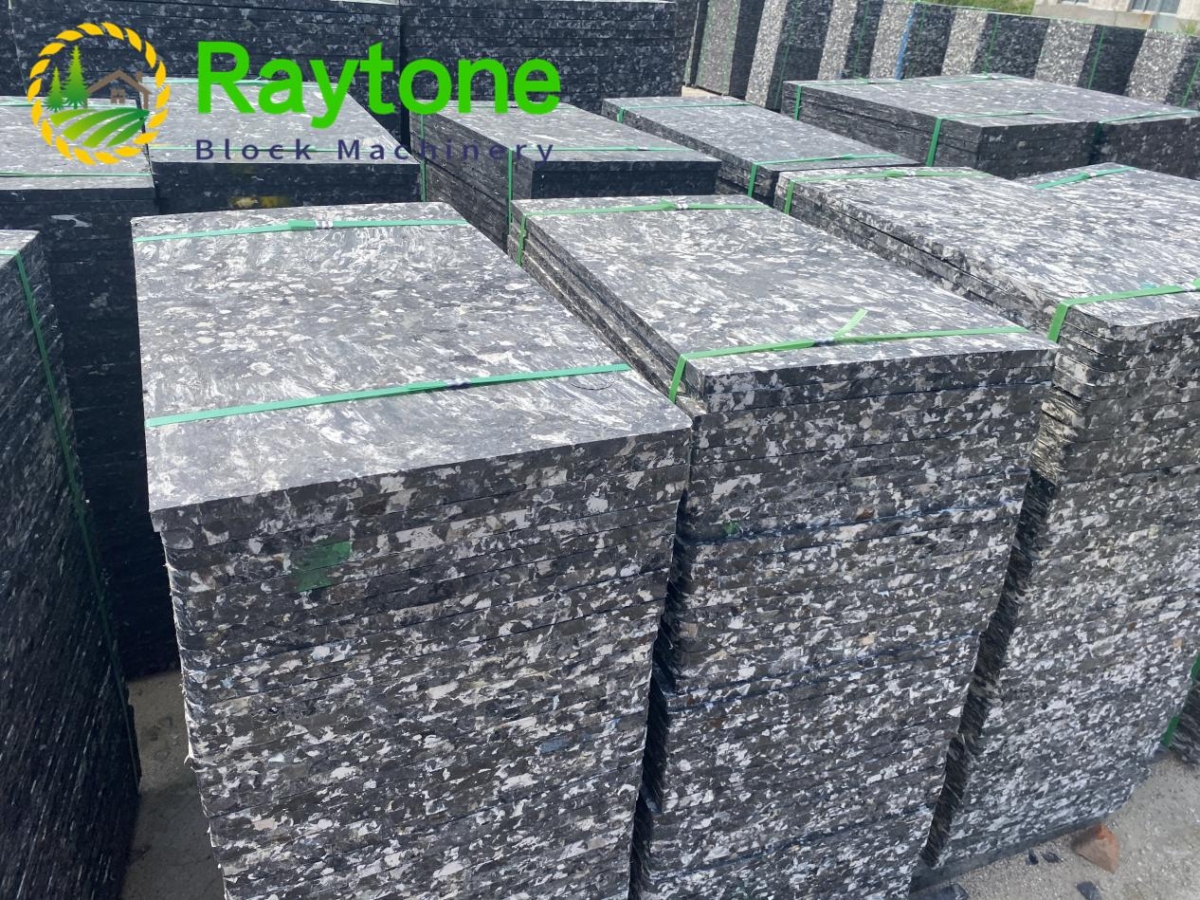

Our bier’s block machine are advanced technology block making machines that use hydraulic pressure to compress and shape raw materials such as Slate, cement and aggregate into high quality concrete blocks. We offer a variety of models with varying production capabilities and customizable features to meet our customers’ specific needs. Our machines are designed for efficiency and durability, with rugged construction and high-quality components ensuring long-term reliability and low maintenance costs.

In addition to producing traditional blocks, our machines are also capable of producing Keyblocks, hollow blocks and paving blocks in a variety of surface finishes such as smooth, textured or coloured. These blocks are widely used in construction projects for building walls, roads, walkways, and other structures.

Equipped with a powerful motor and hydraulic system, the Block Machine is capable of producing up to 10787 bricks per hour. It also features an automatic feeding system, allowing for continuous production without any interruptions. The machine has a PLC control system that ensures precise and accurate production, while also making it user-friendly and easy to operate.

bier’s block machine is a type of equipment used for producing concrete blocks in various shapes and sizes. There are different models of bier’s block machines available in the market, each with its own unique features and capabilities.

QT6-15 Block Making Machine, which is designed for high production and efficiency. This machine is equipped with a large capacity pallet, allowing it to produce six blocks in one cycle. It also has a high pressure hydraulic system, ensuring strong and stable block compression. The QT6-15 is designed with advanced nozzle and mold vibration technology, resulting in precise and high-quality block production.

QT5-15 Concrete Block Molding Machine, which is suitable for producing various types of concrete blocks, including hollow, solid, and interlocking blocks. It has a powerful vibration system and a multi-source vibration of 360 degrees, which ensures uniform and strong block density. The machine also has a high-speed hydraulic system, allowing for quick and efficient block production.

Both models mentioned above have automatic control systems with PLC and touch screen interface, making it easy to operate and adjust the machine settings. They also have customizable features, such as different molds and block sizes, to cater to various construction needs.

In terms of parameters, the QT6-15 has a production capacity of 8640-11520 blocks per shift, while the QT5-15 can produce 7680-10240 blocks per shift. Both models have a power rating of 27.5 kW and require a voltage of 380V. They also have a weight of approximately 14-15 tons and a compact design for ease of transportation and installation.

| land area | 282 Square Meters | Water Consumption | 2.4 T/day |

| Workshop area | 86 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 3 workers | Power Consumption | 26.5 KW*8 Hours=212 KWH; |

| Cement Consumption | 5.23 Tons per day | Sand consumption | 26.9 tons per day |

| Crushed stones consumption | 37.72 tons per day |

How Block Machines Adapt to Any Project

bier’s block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.Are there pre-programmed block designs available for a bier’s block machine?

3.Can a bier’s block machine produce blocks with varying levels of compressive strength?

4.Can a bier’s block machine be used in disaster relief or emergency situations?

5.About bier’s block machine MOQ

6.Can a bier’s block machine produce different sized blocks?

7.Is a bier’s block machine easy to operate?

8.Can a bier’s block machine be used to produce other building materials besides blocks?

9.How is the weight of a block determined during production?

10.Can a bier’s block machine be used in combination with other building techniques?

11.Are there different levels of automation available for bier’s block machines?

12.Are spare parts readily available for a bier’s block machine?

13.Are there any environmental concerns related to the production of blocks with a bier’s block machine?

14.Can a bier’s block machine be customized to meet specific production needs?

15.What is the size and weight of a typical bier’s block machine?

16.Can a bier’s block machine be operated remotely?

1.How does climate affect the production of blocks with a bier’s block machine?

As one of the top bier’s block machine manufacturers in China, we take this very seriously.

Climate can affect the production of blocks with a block machine in a few ways. In cold climates, the concrete mix may need to be adjusted to ensure that it sets properly. In hot climates, the concrete mix may need to be adjusted to ensure that it does not set too quickly. Additionally, in hot climates, the block machine may need to be cooled to prevent overheating. Finally, in humid climates, the block machine may need to be equipped with a dehumidifier to prevent moisture from affecting the production process.

2.Are there pre-programmed block designs available for a bier’s block machine?

We operate our bier’s block machine business with integrity and honesty.

Yes, some block machines come with pre-programmed block designs. However, many block machines also allow users to create their own custom designs.

3.Can a bier’s block machine produce blocks with varying levels of compressive strength?

Yes, a block machine can produce blocks with varying levels of compressive strength. This is done by adjusting the amount of pressure applied to the blocks during the manufacturing process. The amount of pressure applied can be adjusted to produce blocks with different levels of compressive strength.

4.Can a bier’s block machine be used in disaster relief or emergency situations?

Yes, block machines can be used in disaster relief or emergency situations. Block machines can be used to quickly construct temporary shelters, walls, and other structures that can provide protection and shelter for those affected by a disaster. Block machines can also be used to create roads and pathways for emergency vehicles and personnel to access affected areas.

5.About bier’s block machine MOQ

The minimum order quantity (MOQ) for a block machine will vary depending on the type of machine and the manufacturer. Generally, the MOQ for a block machine is one unit. However, some manufacturers may require a minimum order of multiple units.

6.Can a bier’s block machine produce different sized blocks?

bier’s block machine is not a product only, but also can help you comes to money-making.

Yes, a block machine can produce different sized blocks. Depending on the type of block machine, it can be adjusted to produce blocks of different sizes. Some block machines are designed to produce blocks of a specific size, while others are adjustable to produce blocks of different sizes.

7.Is a bier’s block machine easy to operate?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

Yes, most block machines are designed to be easy to operate. Many modern block machines are automated and require minimal operator input. However, some block machines may require more operator input and knowledge to operate correctly.

8.Can a bier’s block machine be used to produce other building materials besides blocks?

Yes, a block machine can be used to produce other building materials such as pavers, bricks, tiles, and even roof tiles.

9.How is the weight of a block determined during production?

Our bier’s block machine products undergo strict quality control to ensure customer satisfaction.

The weight of a block during production is typically determined by a combination of automated and manual processes. Automated processes may include weighing the block on a scale or using a computer-controlled system to measure the weight. Manual processes may include using a hand-held scale or a balance beam.

10.Can a bier’s block machine be used in combination with other building techniques?

Yes, a block machine can be used in combination with other building techniques. For example, a block machine can be used to create the walls of a building, while other building techniques such as steel framing, masonry, and wood framing can be used to create the roof and other structural elements. Additionally, a block machine can be used to create decorative elements such as columns, arches, and other architectural features.

11.Are there different levels of automation available for bier’s block machines?

We operate our bier’s block machine business with integrity and honesty.

Yes, there are different levels of automation available for block machines. Automation levels range from manual machines to fully automated machines. Manual machines require manual labor to operate, while fully automated machines are capable of producing blocks with minimal human intervention. Automation levels can also vary depending on the type of block machine being used.

12.Are spare parts readily available for a bier’s block machine?

bier’s block machine is not a product only, but also can help you comes to money-making.

Yes, spare parts for block machines are readily available. Many manufacturers offer spare parts for their machines, and there are also third-party suppliers that offer spare parts for a variety of block machines.

13.Are there any environmental concerns related to the production of blocks with a bier’s block machine?

Yes, there are environmental concerns related to the production of blocks with a Block machine. The production of blocks with a Block machine can produce dust, noise, and air pollution. Additionally, the production of blocks with a Block machine can also lead to the depletion of natural resources, such as sand and gravel, which are used in the production process.

14.Can a bier’s block machine be customized to meet specific production needs?

Our company has many years of bier’s block machine experience and expertise.

Yes, block machines can be customized to meet specific production needs. Depending on the type of block machine, customization may include changing the size of the blocks, the speed of the machine, or the type of material used. Additionally, some block machines can be programmed to produce blocks with specific shapes or sizes.

15.What is the size and weight of a typical bier’s block machine?

The size and weight of a typical block machine will vary depending on the type and model of the machine. Generally, block machines range in size from about 4 feet wide by 8 feet long to 8 feet wide by 20 feet long. The weight of a typical block machine can range from 1,000 to 10,000 pounds.

16.Can a bier’s block machine be operated remotely?

Yes, some block machines can be operated remotely. This is usually done through a computer or mobile device, and the machine can be programmed to run automatically.