- 20

- 12月

compressed wood pallet block machine

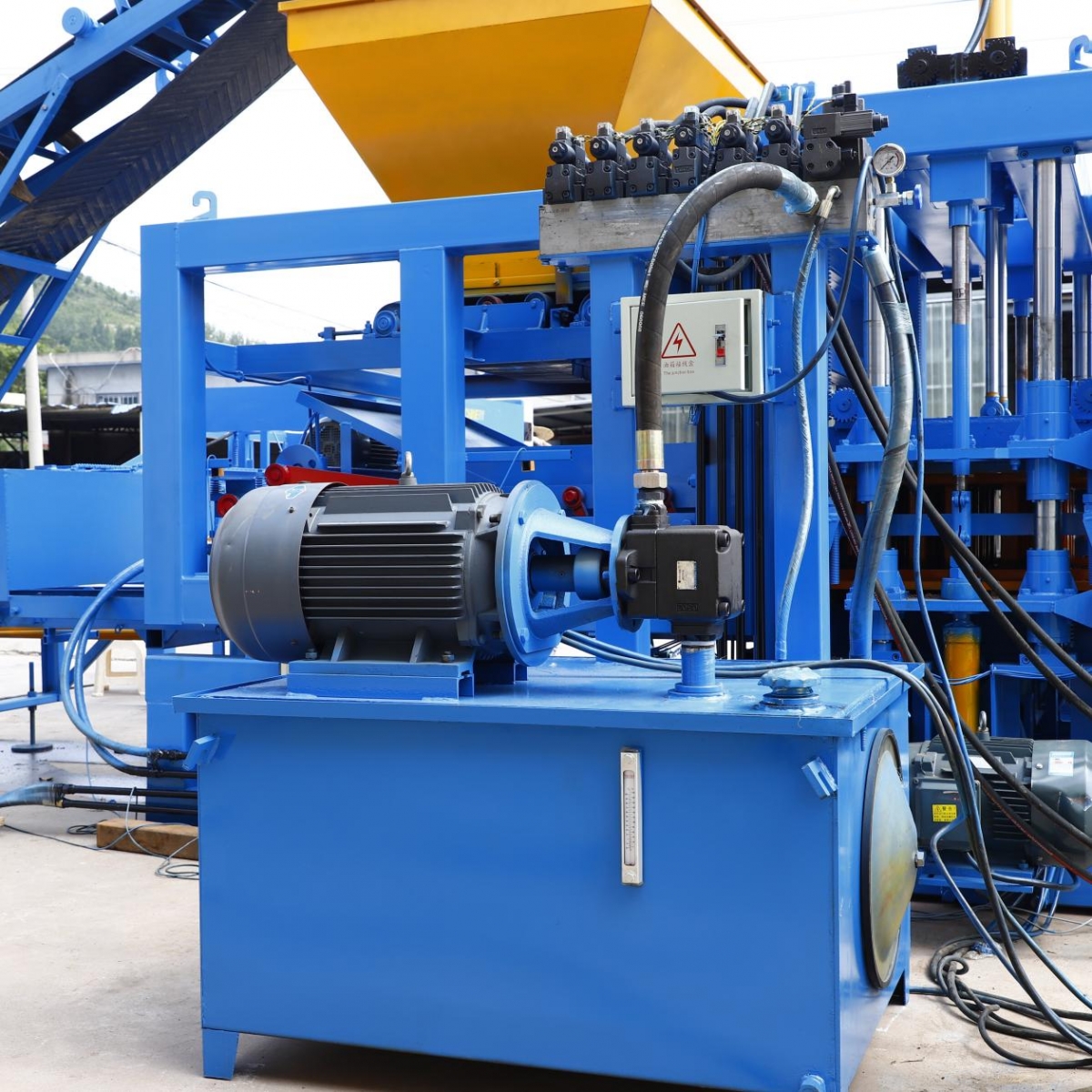

Introducing our highly efficient and versatile compressed wood pallet block machine – the perfect solution for all your Chimney blocks production needs.

Designed with advanced technology and precision engineering, our block making machines are capable of producing a variety of Chimney blocks including standard blocks, hollow blocks, interlocking blocks and paving blocks. This makes it ideal for use in the construction of residential, commercial and industrial buildings.

Equipped with a sturdy steel frame and a powerful motor, our block making machines can easily produce up to 11053 of blocks per hour, saving you time and labor costs. It has a versatile mold configuration that can manufacture a variety of block types and sizes, from standard Chimney blocks to interlocking and Road and highway construction.

One of the popular models is the QT4-15 compressed wood pallet block machine, which has a production capacity of 800-2323 blocks per hour. It is equipped with an automatic control system and hydraulic components, making it easy to operate and maintain. The machine is also designed with a vibrating system, ensuring the even distribution of materials for consistent block quality. Its compact design allows for space-saving installation, making it suitable for both small and large scale production.

In terms of parameters, the QT4-15 compressed wood pallet block machine can produce standard bricks, hollow blocks, and other custom shapes with adjustable mold height and vibration frequency. It also has a hopper size of 800x800mm and a conveyor belt for efficient material feeding. Additionally, it has a power output of 24.5kw, ensuring high production speed and energy efficiency.

| land area | 306 Square Meters | Water Consumption | 2.4 T/day |

| Workshop area | 94 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 3 workers | Power Consumption | 26.5 KW*8 Hours=212 KWH; |

| Cement Consumption | 8.52 Tons per day | Sand consumption | 27.9 tons per day |

| Crushed stones consumption | 36.51 tons per day |

Block Machines Redefining Building Standards

compressed wood pallet block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.About compressed wood pallet block machine quality system

3.Can a compressed wood pallet block machine be used for both indoor and outdoor construction projects?

4.Are there any noise or vibration concerns with a compressed wood pallet block machine?

5.About compressed wood pallet block machine payment method

6.What types of blocks can a compressed wood pallet block machine produce?

7.Can a compressed wood pallet block machine be used to produce other building materials besides blocks?

8.What is the production capacity of a compressed wood pallet block machine?

9.Can a compressed wood pallet block machine be used in areas with limited access to electricity?

10.About compressed wood pallet block machine delivery date

11.How often does a compressed wood pallet block machine need to be maintained?

12.About compressed wood pallet block machine technology

13.Are there safety precautions that need to be taken while operating a compressed wood pallet block machine?

14.How does a compressed wood pallet block machine handle different types of soils?

1.Can a compressed wood pallet block machine be connected to other construction equipment for seamless production?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

Yes, a block machine can be connected to other construction equipment for seamless production. This is done by using a conveyor system to move the blocks from the block machine to other construction equipment, such as a mixer, for further processing. This allows for a more efficient and automated production process.

2.About compressed wood pallet block machine quality system

A block machine quality system is a set of procedures and processes that are used to ensure that the block machines manufactured by a company meet the highest standards of quality. The system includes the use of quality control measures such as inspections, testing, and documentation to ensure that the block machines are safe and reliable. The system also includes the use of quality assurance measures such as training, auditing, and corrective action plans to ensure that the block machines are consistently meeting the required standards. The system also includes the use of preventive maintenance measures such as regular maintenance and repairs to ensure that the block machines are operating at peak efficiency.

3.Can a compressed wood pallet block machine be used for both indoor and outdoor construction projects?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

Yes, a block machine can be used for both indoor and outdoor construction projects. However, the type of block machine used will depend on the specific project requirements. For example, a block machine designed for outdoor projects may be more powerful and durable than one designed for indoor projects.

4.Are there any noise or vibration concerns with a compressed wood pallet block machine?

Yes, noise and vibration are common concerns with block machines. The noise and vibration levels can vary depending on the type of machine and the materials being used. It is important to ensure that the machine is properly maintained and that the operator is properly trained to reduce the risk of excessive noise and vibration.

5.About compressed wood pallet block machine payment method

Block machine payment methods vary depending on the manufacturer and the type of machine. Some common payment methods include cash, credit cards, PayPal, wire transfers, and cryptocurrency. Some manufacturers may also offer financing options or leasing options.

6.What types of blocks can a compressed wood pallet block machine produce?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

A block machine can produce a variety of blocks, including concrete blocks, cinder blocks, interlocking blocks, retaining wall blocks, and paving blocks.

7.Can a compressed wood pallet block machine be used to produce other building materials besides blocks?

Yes, a block machine can be used to produce other building materials such as pavers, bricks, tiles, and even roof tiles.

8.What is the production capacity of a compressed wood pallet block machine?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

The production capacity of a block machine depends on the size and type of block being produced. Generally, a block machine can produce between 1,000 and 8,000 blocks per hour.

9.Can a compressed wood pallet block machine be used in areas with limited access to electricity?

We are a professional compressed wood pallet block machine company dedicated to providing high quality products and services.

Yes, some block machines can be used in areas with limited access to electricity. Some block machines are powered by diesel engines, which can be used in areas with limited access to electricity.

10.About compressed wood pallet block machine delivery date

The delivery date of a block machine will depend on the type of machine, the manufacturer, and the availability of the machine. Generally, most block machines can be delivered within 4-6 weeks of ordering. However, some manufacturers may have longer lead times due to production schedules or other factors. It is best to contact the manufacturer directly to get an accurate delivery date.

11.How often does a compressed wood pallet block machine need to be maintained?

We focus on innovation and continuous improvement to maintain a competitive advantage.

A block machine should be maintained on a regular basis, typically every 3-6 months depending on the type of machine and its usage. Regular maintenance should include checking for wear and tear, lubricating moving parts, and inspecting the machine for any potential safety hazards.

12.About compressed wood pallet block machine technology

Block machine technology is a type of construction technology that is used to produce concrete blocks. It is a process that involves mixing cement, sand, and water to form a concrete mixture, which is then poured into a mold and compressed to form a block. The blocks are then cured and hardened before being used in construction projects. Block machine technology has been used for centuries to create strong and durable structures. It is a cost-effective and efficient way to build structures that are both aesthetically pleasing and structurally sound.

13.Are there safety precautions that need to be taken while operating a compressed wood pallet block machine?

As one of the top compressed wood pallet block machine manufacturers in China, we take this very seriously.

Yes, there are several safety precautions that should be taken when operating a block machine. These include:

1. Wear appropriate safety gear, such as safety glasses, gloves, and a hard hat.

2. Make sure the machine is properly grounded and that all electrical connections are secure.

3. Ensure that the machine is properly lubricated and that all moving parts are in good working order.

4. Keep the work area clean and free of debris.

5. Make sure that all guards and safety devices are in place and functioning properly.

6. Make sure that all operators are properly trained and familiar with the machine’s operation.

7. Make sure that all operators are aware of the potential hazards associated with the machine and take the necessary precautions to avoid them.

8. Make sure that all operators are aware of the emergency stop button and know how to use it in case of an emergency.

14.How does a compressed wood pallet block machine handle different types of soils?

A block machine is designed to handle a variety of soils, including clay, sand, gravel, and other aggregates. Depending on the type of soil, the machine may need to be adjusted to ensure the blocks are formed correctly. For example, if the soil is clay-based, the machine may need to be adjusted to increase the pressure and vibration to ensure the blocks are formed correctly. Additionally, the machine may need to be adjusted to ensure the blocks are formed with the correct amount of moisture.