- 20

- 12月

dry ice block machine

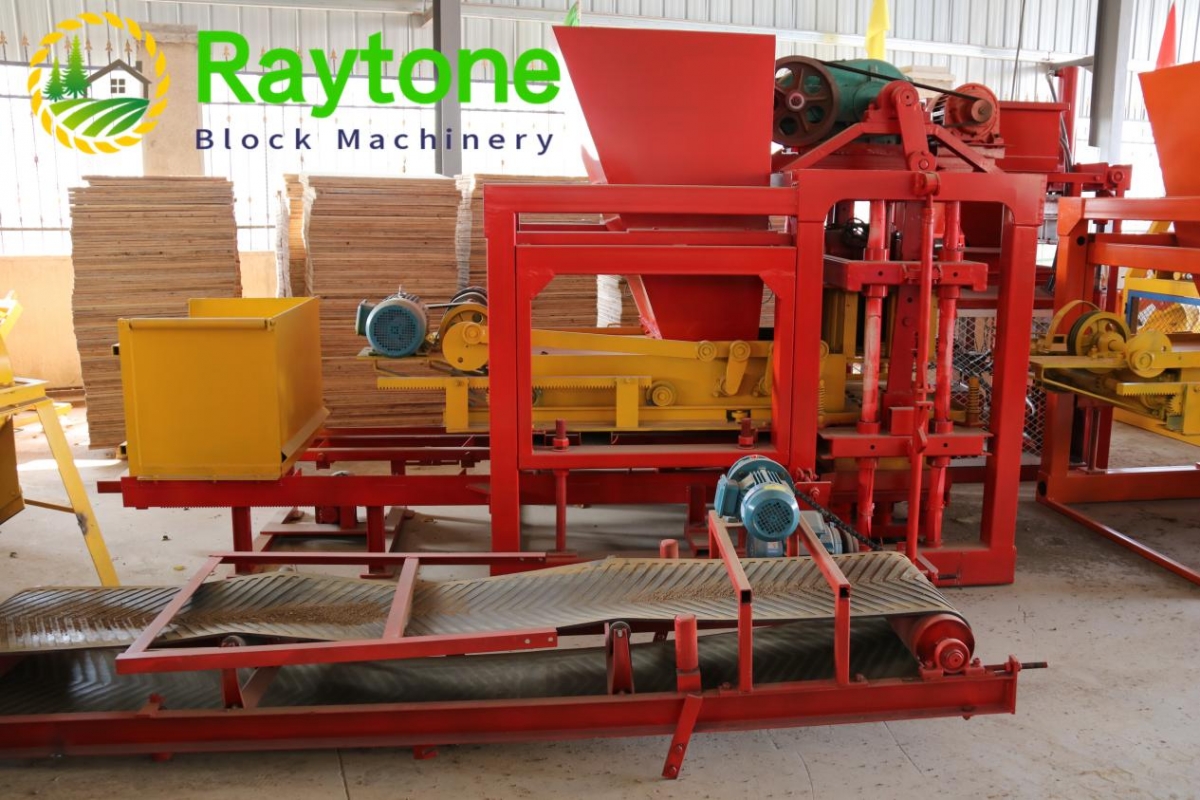

dry ice block machine is an innovative and high-quality construction machinery designed to produce blocks or bricks from various raw materials such as cement, sand, gravel, stone powder, Capping blocks and more. It is widely used in the construction industry for building walls, pavements, and other structures.

This machine is equipped with advanced technology and components that ensure efficient and precise block production. It operates through a hydraulic system, which provides a consistent and smooth movement of the machine, resulting in higher production rates and excellent block quality.

Our dry ice block machine is available in various models and comes with a range of different parameters to cater to your specific needs. The models include the QMJ4-35, QTJ4-26C, QT5-15, and QT8-15, each offering unique features and capabilities.

The QMJ4-35 model is a small and compact machine, ideal for projects with limited space. It has a production capacity of 400 to $keyworrd{36} blocks per hour and a power consumption of 11.25 kW. The QTJ4-26C model is an upgraded version with a higher production capacity of 800 to 1547 blocks per hour and a lower power consumption of 9.6 kW.

For larger projects, the QT5-15 model is a perfect choice with a production capacity of 6077 to 8575 blocks per 8 hours, and a power consumption of 21 kW. It also comes with a hydraulic system for more efficient and precise operation. The QT8-15 model is our most advanced and largest model, with a production capacity of 9600 to 12000 blocks per 8 hours and a power consumption of 51 kW. It also has an intelligent PLC control system for automated operation.

In addition to these models, we offer various configurations for different block sizes and shapes, such as hollow blocks, solid blocks, and interlocking blocks. Our dry ice block machine is also equipped with high-quality motors and hydraulic components for reliable and durable performance. With our customizable options and reliable technology, our dry ice block machine is the perfect solution for all your block-making needs.

| (1) | Dimension of host machine | 2779*2000*2000mm | (6) | labour | 4 workers |

| (2) | Weight of the host machine | 3.2T | (7) | Voltage | customized |

| (3) | Moulding period | 25-28 | (8) | Total required machine power | 26.5 KW |

| (4) | pallet size | 850*550*20mm | (9) | Diesel Generator capacity | 35.62KVA |

| (5) | Vibration force | 58KN | (10) | workshop area | 344 m2 |

How Block Machines Adapt to Any Project

dry ice block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.About dry ice block machine MOQ

3.About the development history of dry ice block machine factory

4.About dry ice block machine production management system

5.Is there a specific curing process for blocks produced by a dry ice block machine?

6.About dry ice block machine patent

7.About dry ice block machine warranty

8.How does a dry ice block machine handle different types of soils?

9.What is the expected return on investment for a dry ice block machine?

10.Can a dry ice block machine produce eco-friendly blocks?

11.About dry ice block machine overseas warehouse

12.Are there any design limitations when using a dry ice block machine?

13.What is the power source for a dry ice block machine?

14.About dry ice block machine inventory

15.How is the weight of a block determined during production?

1.Are spare parts readily available for a dry ice block machine?

dry ice block machine is not a product only, but also can help you comes to money-making.

Yes, spare parts for block machines are readily available. Many manufacturers offer spare parts for their machines, and there are also third-party suppliers that offer spare parts for a variety of block machines.

2.About dry ice block machine MOQ

The minimum order quantity (MOQ) for a block machine will vary depending on the type of machine and the manufacturer. Generally, the MOQ for a block machine is one unit. However, some manufacturers may require a minimum order of multiple units.

3.About the development history of dry ice block machine factory

The development history of block machine factory can be traced back to the early 20th century. The first block machine was invented in the United States in 1905 by a man named Charles Pankow. This machine was used to make concrete blocks for construction projects. In the 1920s, the first automatic block machine was developed in Germany. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines.

In the 1950s, the first hydraulic block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines. In the 1960s, the first computer-controlled block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines.

In the 1970s, the first fully automated block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines. In the 1980s, the first robotic block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines.

Today, block machine factories are used to produce a wide variety of blocks for construction projects. They are used to produce blocks for residential, commercial, and industrial projects. Block machine factories are also used to produce blocks for landscaping projects.

4.About dry ice block machine production management system

The Block machine production management system is a software solution designed to help businesses manage the production of concrete blocks. It provides a comprehensive set of tools to help businesses track and manage the production process from start to finish. The system can be used to monitor production, track inventory, manage orders, and generate reports. It also provides features such as scheduling, cost tracking, and quality control. The system is designed to be user-friendly and can be customized to meet the specific needs of each business.

5.Is there a specific curing process for blocks produced by a dry ice block machine?

Yes, there is a specific curing process for blocks produced by a block machine. The curing process typically involves keeping the blocks in a moist environment for a period of time, usually between 7 and 28 days. This allows the blocks to dry slowly and evenly, which helps to ensure that they are strong and durable.

6.About dry ice block machine patent

Block machine patents are patents that cover the design and operation of machines used to make blocks of various materials, such as concrete, clay, and other masonry materials. These machines are used in the construction industry to create walls, foundations, and other structures. Block machine patents typically cover the design of the machine, the operation of the machine, and the materials used in the production of blocks.

7.About dry ice block machine warranty

Block machine warranties vary depending on the manufacturer and model. Generally, warranties cover defects in materials and workmanship for a certain period of time, usually one year. Some warranties may also cover parts and labor for a certain period of time. It is important to read the warranty information carefully to understand what is covered and for how long.

8.How does a dry ice block machine handle different types of soils?

A block machine is designed to handle a variety of soils, including clay, sand, gravel, and other aggregates. Depending on the type of soil, the machine may need to be adjusted to ensure the blocks are formed correctly. For example, if the soil is clay-based, the machine may need to be adjusted to increase the pressure and vibration to ensure the blocks are formed correctly. Additionally, the machine may need to be adjusted to ensure the blocks are formed with the correct amount of moisture.

9.What is the expected return on investment for a dry ice block machine?

The expected return on investment for a block machine can vary greatly depending on the type of machine, the size of the project, and the market conditions. Generally, block machines can have a return on investment of anywhere from 10-30%, with some machines having returns as high as 50%.

10.Can a dry ice block machine produce eco-friendly blocks?

As one of the dry ice block machine market leaders, we are known for innovation and reliability.

Yes, a block machine can produce eco-friendly blocks. Many block machines are designed to produce blocks that are made from recycled materials, such as plastic, glass, and other materials. These blocks are often referred to as green blocks” and are becoming increasingly popular as a sustainable building material.”

11.About dry ice block machine overseas warehouse

Block machine overseas warehouses are warehouses located in different countries around the world that store and distribute block machines. These warehouses are used to store and ship block machines to customers in different countries. The warehouses are typically owned and operated by the block machine manufacturer or distributor. They are responsible for ensuring that the block machines are properly stored and shipped to customers in a timely manner.

12.Are there any design limitations when using a dry ice block machine?

Yes, there are several design limitations when using a block machine. These include the size of the blocks that can be produced, the type of material that can be used, the speed of production, and the amount of force that can be applied to the blocks. Additionally, the block machine may not be able to produce blocks with intricate designs or shapes.

13.What is the power source for a dry ice block machine?

Our products & services cover a wide range of areas and meet the needs of different fields.

The power source for a block machine is typically an electric motor. Some block machines may also be powered by a diesel engine.

14.About dry ice block machine inventory

Block machine inventory is a software system designed to help businesses manage their inventory of block machines. The system allows businesses to track the quantity of block machines in stock, the cost of each machine, and the location of each machine. The system also provides reports on the current inventory levels, the cost of each machine, and the location of each machine. Additionally, the system can be used to generate purchase orders and invoices for block machines.

15.How is the weight of a block determined during production?

Our dry ice block machine products undergo strict quality control to ensure customer satisfaction.

The weight of a block during production is typically determined by a combination of automated and manual processes. Automated processes may include weighing the block on a scale or using a computer-controlled system to measure the weight. Manual processes may include using a hand-held scale or a balance beam.