- 21

- 12月

high quality concrete block machine

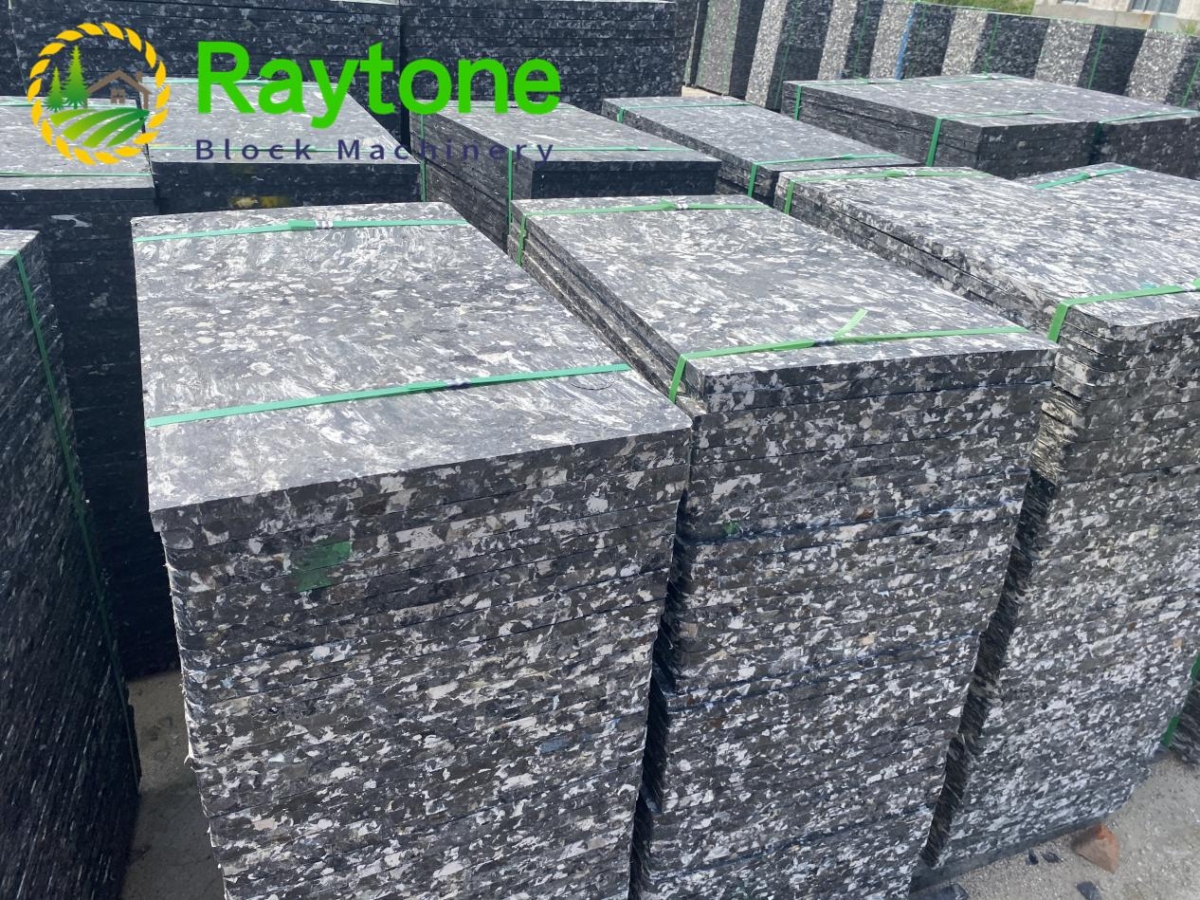

Our high quality concrete block machine are advanced technology block making machines that use hydraulic pressure to compress and shape raw materials such as Pumice, cement and aggregate into high quality concrete blocks. We offer a variety of models with varying production capabilities and customizable features to meet our customers’ specific needs. Our machines are designed for efficiency and durability, with rugged construction and high-quality components ensuring long-term reliability and low maintenance costs.

In addition to producing traditional blocks, our machines are also capable of producing Manhole blocks, hollow blocks and paving blocks in a variety of surface finishes such as smooth, textured or coloured. These blocks are widely used in construction projects for building walls, roads, walkways, and other structures.

Briefly about our block machines:

The QT12-15 is the biggest fully automatic block making machine with high productivity , it is suitable for big company who want to supply big projects;

the QT4-18 simple automatic block making machine is one the best selling brick machine model, because of its high cost to performance.

The QT4-24 semi automatic brick machine is also very popular because its low price and easy operating system;

The QT4-40 manual block making machine is very cheap for small investment, it can also make different blocks, bricks under different block moulds.

Other QT4-15 QT6-15 QT8-15 QT10-15 block machine models are mainly middle scale automatic brick machine line, they have different capacity and superiority;

As China Block Machine Factory, we would like to cooperate with the block machine Wholesaler from the world, communicate with the block machine factory supplier from the world to make progress together.

| (1) | Dimension of host machine | 2766*2000*2000mm | (6) | labour | 4 workers |

| (2) | Weight of the host machine | 3.2T | (7) | Voltage | customized |

| (3) | Moulding period | 25-28 | (8) | Total required machine power | 26.5 KW |

| (4) | pallet size | 850*550*20mm | (9) | Diesel Generator capacity | 36.99KVA |

| (5) | Vibration force | 73KN | (10) | workshop area | 374 m2 |

The Time-Saving Features of Modern Block Machines

high quality concrete block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.Can a high quality concrete block machine be easily repaired in case of breakdown?

3.Does a high quality concrete block machine require a specific type of raw material?

4.How does the cost of a high quality concrete block machine compare to traditional building materials?

5.Can a high quality concrete block machine be used for both indoor and outdoor construction projects?

6.Can a high quality concrete block machine be used for large scale production?

7.About high quality concrete block machine production equipment

8.Are there any special requirements for maintenance and storage of a high quality concrete block machine?

9.About high quality concrete block machine R&D capabilities

10.How much space is needed to operate a high quality concrete block machine?

11.About high quality concrete block machine patent

12.Can a high quality concrete block machine be customized to meet specific production needs?

13.How does a high quality concrete block machine handle different types of soils?

14.About the development history of high quality concrete block machine factory

15.What is the cost-effectiveness of using a high quality concrete block machine?

1.Is there a specific curing process for blocks produced by a high quality concrete block machine?

Yes, there is a specific curing process for blocks produced by a block machine. The curing process typically involves keeping the blocks in a moist environment for a period of time, usually between 7 and 28 days. This allows the blocks to dry slowly and evenly, which helps to ensure that they are strong and durable.

2.Can a high quality concrete block machine be easily repaired in case of breakdown?

Yes, a block machine can be easily repaired in case of breakdown. Depending on the type of block machine, the repair process may involve replacing parts, cleaning and lubricating components, or adjusting settings. In some cases, a technician may need to be called in to diagnose and repair the machine.

3.Does a high quality concrete block machine require a specific type of raw material?

Our high quality concrete block machine products undergo strict quality control to ensure customer satisfaction.

Yes, a block machine typically requires a specific type of raw material, such as sand, gravel, cement, and water. Depending on the type of block machine, other materials may also be required.

4.How does the cost of a high quality concrete block machine compare to traditional building materials?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

The cost of a block machine is typically much higher than traditional building materials. Block machines are typically used to produce large quantities of blocks, which can be expensive to purchase in bulk. Additionally, block machines require specialized equipment and expertise to operate, which can add to the cost.

5.Can a high quality concrete block machine be used for both indoor and outdoor construction projects?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

Yes, a block machine can be used for both indoor and outdoor construction projects. However, the type of block machine used will depend on the specific project requirements. For example, a block machine designed for outdoor projects may be more powerful and durable than one designed for indoor projects.

6.Can a high quality concrete block machine be used for large scale production?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, block machines can be used for large scale production. Block machines are designed to produce large quantities of concrete blocks in a short amount of time. They are typically used in the construction industry to produce blocks for walls, foundations, and other structures.

7.About high quality concrete block machine production equipment

Block machine production equipment is used to produce concrete blocks, bricks, and other masonry products. This equipment typically includes a mixer, a block machine, a conveyor, and a curing chamber. The mixer is used to mix the concrete, while the block machine is used to form the blocks. The conveyor is used to move the blocks to the curing chamber, where they are cured and hardened. The equipment is typically powered by electricity or diesel fuel.

8.Are there any special requirements for maintenance and storage of a high quality concrete block machine?

Our company has many years of high quality concrete block machine experience and expertise.

Yes, there are special requirements for maintenance and storage of a block machine. It is important to keep the machine clean and free of debris, as well as to lubricate all moving parts regularly. Additionally, the machine should be stored in a dry, dust-free environment and away from direct sunlight.

9.About high quality concrete block machine R&D capabilities

Block machine R&D capabilities refer to the ability of a company to research, develop, and manufacture block machines. This includes the ability to design and develop new block machines, as well as the ability to modify existing block machines to meet customer needs. Companies with strong R&D capabilities are able to create innovative block machines that are more efficient, reliable, and cost-effective than those of their competitors. Additionally, companies with strong R&D capabilities are able to quickly respond to customer needs and develop new block machines to meet changing market demands.

10.How much space is needed to operate a high quality concrete block machine?

We have established a good reputation and reliable partnerships within the high quality concrete block machine industry.

The amount of space needed to operate a block machine will depend on the size and type of machine. Generally, a block machine will require a minimum of 10 feet by 10 feet of space.

11.About high quality concrete block machine patent

Block machine patents are patents that cover the design and operation of machines used to make blocks of various materials, such as concrete, clay, and other masonry materials. These machines are used in the construction industry to create walls, foundations, and other structures. Block machine patents typically cover the design of the machine, the operation of the machine, and the materials used in the production of blocks.

12.Can a high quality concrete block machine be customized to meet specific production needs?

Our company has many years of high quality concrete block machine experience and expertise.

Yes, block machines can be customized to meet specific production needs. Depending on the type of block machine, customization may include changing the size of the blocks, the speed of the machine, or the type of material used. Additionally, some block machines can be programmed to produce blocks with specific shapes or sizes.

13.How does a high quality concrete block machine handle different types of soils?

A block machine is designed to handle a variety of soils, including clay, sand, gravel, and other aggregates. Depending on the type of soil, the machine may need to be adjusted to ensure the blocks are formed correctly. For example, if the soil is clay-based, the machine may need to be adjusted to increase the pressure and vibration to ensure the blocks are formed correctly. Additionally, the machine may need to be adjusted to ensure the blocks are formed with the correct amount of moisture.

14.About the development history of high quality concrete block machine factory

The development history of block machine factory can be traced back to the early 20th century. The first block machine was invented in the United States in 1905 by a man named Charles Pankow. This machine was used to make concrete blocks for construction projects. In the 1920s, the first automatic block machine was developed in Germany. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines.

In the 1950s, the first hydraulic block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines. In the 1960s, the first computer-controlled block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines.

In the 1970s, the first fully automated block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines. In the 1980s, the first robotic block machine was developed in the United States. This machine was able to produce blocks with a higher degree of accuracy and consistency than the manual machines.

Today, block machine factories are used to produce a wide variety of blocks for construction projects. They are used to produce blocks for residential, commercial, and industrial projects. Block machine factories are also used to produce blocks for landscaping projects.

15.What is the cost-effectiveness of using a high quality concrete block machine?

The cost-effectiveness of using a block machine depends on the type of block machine being used, the size of the project, and the amount of labor required. Generally, block machines are more cost-effective than traditional methods of block production, as they require less labor and can produce more blocks in a shorter amount of time. Additionally, block machines can produce blocks with a higher degree of accuracy and uniformity than traditional methods, which can result in a higher quality product.