- 21

- 12月

semi automatic block machine

One of the key features of our semi automatic block machine

is its user-friendly design. It is equipped with a computerized control system, making it easy to operate and monitor. The control panel allows for precision and flexibility in adjusting the production process, ensuring consistent and high-quality blocks every time.

In addition, our block machines are also environmentally friendly. They have a low carbon footprint, consume minimal amounts of energy, and produce minimal waste, making them an ideal choice for sustainable construction and High-rise building construction.

Our semi automatic block machine is available in various models and comes with a range of different parameters to cater to your specific needs. The models include the QMJ4-35, QTJ4-26C, QT5-15, and QT8-15, each offering unique features and capabilities.

The QMJ4-35 model is a small and compact machine, ideal for projects with limited space. It has a production capacity of 400 to $keyworrd{36} blocks per hour and a power consumption of 11.25 kW. The QTJ4-26C model is an upgraded version with a higher production capacity of 800 to 1229 blocks per hour and a lower power consumption of 9.6 kW.

For larger projects, the QT5-15 model is a perfect choice with a production capacity of 6171 to 8122 blocks per 8 hours, and a power consumption of 21 kW. It also comes with a hydraulic system for more efficient and precise operation. The QT8-15 model is our most advanced and largest model, with a production capacity of 9600 to 12000 blocks per 8 hours and a power consumption of 51 kW. It also has an intelligent PLC control system for automated operation.

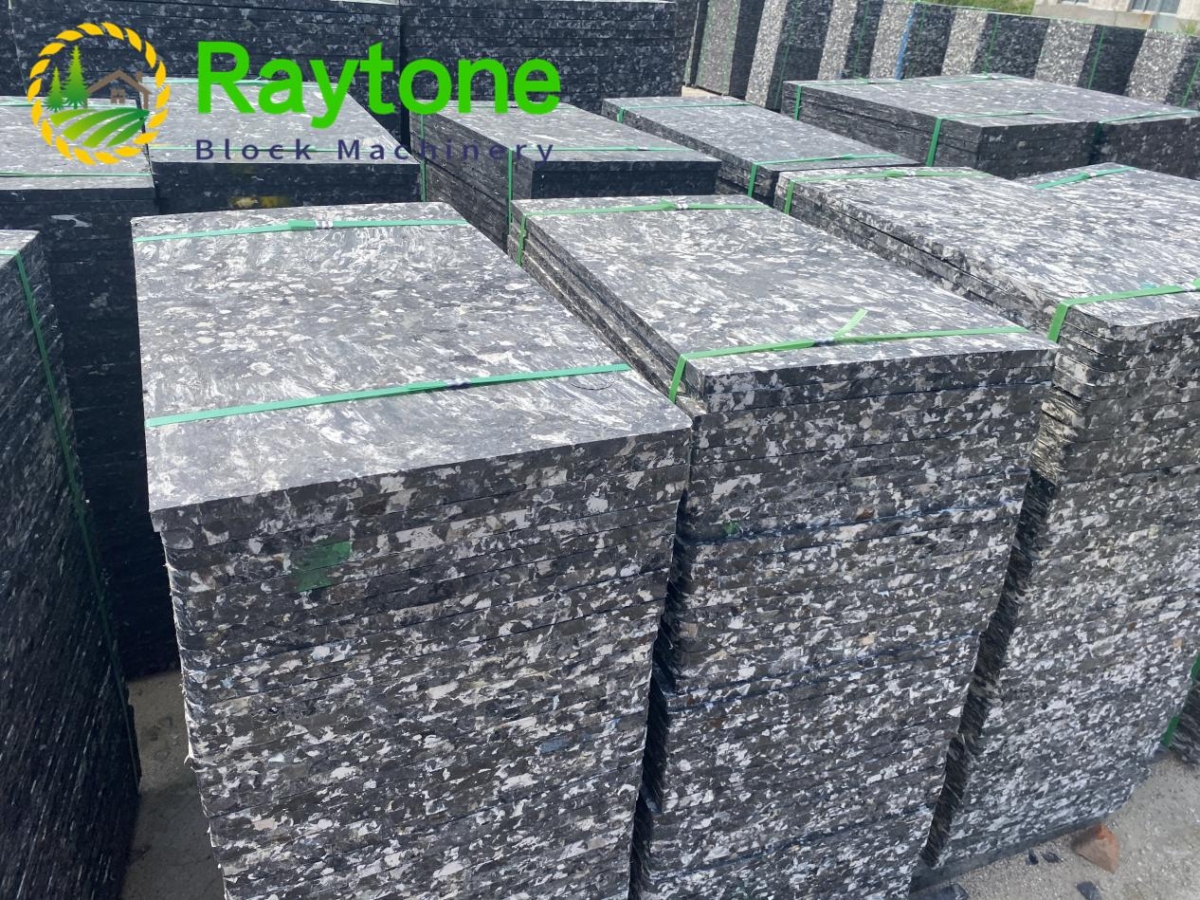

In addition to these models, we offer various configurations for different block sizes and shapes, such as hollow blocks, solid blocks, and interlocking blocks. Our semi automatic block machine is also equipped with high-quality motors and hydraulic components for reliable and durable performance. With our customizable options and reliable technology, our semi automatic block machine is the perfect solution for all your block-making needs.

| land area | 305 Square Meters | Water Consumption | 2.4 T/day |

| Workshop area | 95 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 3 workers | Power Consumption | 26.5 KW*8 Hours=212 KWH; |

| Cement Consumption | 5.78 Tons per day | Sand consumption | 27.2 tons per day |

| Crushed stones consumption | 31.95 tons per day |

How Block Machines Adapt to Any Project

semi automatic block machine FAQs Guide.

The Block machine is an innovative and advanced piece of equipment that is designed to streamline the process of creating high-quality concrete blocks. With its state-of-the-art technology and precise engineering, our Block machine offers superior performance and efficiency for any construction project. It is a versatile and reliable tool that can produce a wide range of block sizes and shapes, making it perfect for various applications, including residential and commercial buildings, road and sidewalk construction, and more. Combined with its durability and ease of use, our Block machine is the ideal solution for your block-making needs. Join the countless satisfied customers who have experienced the benefits of our Block machine and take your construction projects to the next level.

2.Can a semi automatic block machine be easily repaired in case of breakdown?

3.How does the cost of a semi automatic block machine compare to traditional building materials?

4.About semi automatic block machine production capacity

5.What is the cost-effectiveness of using a semi automatic block machine?

6.Can a semi automatic block machine be moved easily?

7.Can a semi automatic block machine produce blocks of varying shapes?

8.Are there pre-programmed block designs available for a semi automatic block machine?

9.Are there any special requirements for maintenance and storage of a semi automatic block machine?

10.Can a semi automatic block machine be connected to other construction equipment for seamless production?

11.Are spare parts readily available for a semi automatic block machine?

12.Can a semi automatic block machine be operated by one person?

13.What materials are commonly used in a semi automatic block machine?

14.Can a semi automatic block machine be used in disaster relief or emergency situations?

1.How does a semi automatic block machine handle different types of soils?

A block machine is designed to handle a variety of soils, including clay, sand, gravel, and other aggregates. Depending on the type of soil, the machine may need to be adjusted to ensure the blocks are formed correctly. For example, if the soil is clay-based, the machine may need to be adjusted to increase the pressure and vibration to ensure the blocks are formed correctly. Additionally, the machine may need to be adjusted to ensure the blocks are formed with the correct amount of moisture.

2.Can a semi automatic block machine be easily repaired in case of breakdown?

Yes, a block machine can be easily repaired in case of breakdown. Depending on the type of block machine, the repair process may involve replacing parts, cleaning and lubricating components, or adjusting settings. In some cases, a technician may need to be called in to diagnose and repair the machine.

3.How does the cost of a semi automatic block machine compare to traditional building materials?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

The cost of a block machine is typically much higher than traditional building materials. Block machines are typically used to produce large quantities of blocks, which can be expensive to purchase in bulk. Additionally, block machines require specialized equipment and expertise to operate, which can add to the cost.

4.About semi automatic block machine production capacity

The production capacity of a block machine depends on the size of the blocks it is producing, the type of material being used, and the speed of the machine. Generally, a block machine can produce between 500 and 5,000 blocks per hour.

5.What is the cost-effectiveness of using a semi automatic block machine?

The cost-effectiveness of using a block machine depends on the type of block machine being used, the size of the project, and the amount of labor required. Generally, block machines are more cost-effective than traditional methods of block production, as they require less labor and can produce more blocks in a shorter amount of time. Additionally, block machines can produce blocks with a higher degree of accuracy and uniformity than traditional methods, which can result in a higher quality product.

6.Can a semi automatic block machine be moved easily?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

Yes, block machines can be moved easily. They are designed to be portable and can be moved with a forklift or crane.

7.Can a semi automatic block machine produce blocks of varying shapes?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, a block machine can produce blocks of varying shapes. Block machines are designed to produce blocks of different sizes and shapes, depending on the type of block machine and the type of block being produced. Some block machines are capable of producing blocks with complex shapes, such as interlocking blocks, while others are limited to producing blocks with basic shapes, such as rectangular blocks.

8.Are there pre-programmed block designs available for a semi automatic block machine?

We operate our semi automatic block machine business with integrity and honesty.

Yes, some block machines come with pre-programmed block designs. However, many block machines also allow users to create their own custom designs.

9.Are there any special requirements for maintenance and storage of a semi automatic block machine?

Our company has many years of semi automatic block machine experience and expertise.

Yes, there are special requirements for maintenance and storage of a block machine. It is important to keep the machine clean and free of debris, as well as to lubricate all moving parts regularly. Additionally, the machine should be stored in a dry, dust-free environment and away from direct sunlight.

10.Can a semi automatic block machine be connected to other construction equipment for seamless production?

We focus on our customers’ needs and strive to meet their expectations, so we take this very seriously.

Yes, a block machine can be connected to other construction equipment for seamless production. This is done by using a conveyor system to move the blocks from the block machine to other construction equipment, such as a mixer, for further processing. This allows for a more efficient and automated production process.

11.Are spare parts readily available for a semi automatic block machine?

semi automatic block machine is not a product only, but also can help you comes to money-making.

Yes, spare parts for block machines are readily available. Many manufacturers offer spare parts for their machines, and there are also third-party suppliers that offer spare parts for a variety of block machines.

12.Can a semi automatic block machine be operated by one person?

Yes, a block machine can be operated by one person. However, it is recommended that two people operate the machine for safety reasons.

13.What materials are commonly used in a semi automatic block machine?

Our mission is to provide customers with the best solutions for semi automatic block machine.

Common materials used in block machines include concrete, sand, gravel, cement, and water. Depending on the type of block being made, other materials such as steel, plastic, and wood may also be used.

14.Can a semi automatic block machine be used in disaster relief or emergency situations?

Yes, block machines can be used in disaster relief or emergency situations. Block machines can be used to quickly construct temporary shelters, walls, and other structures that can provide protection and shelter for those affected by a disaster. Block machines can also be used to create roads and pathways for emergency vehicles and personnel to access affected areas.