- 28

- 2月

How does a block making machine work?

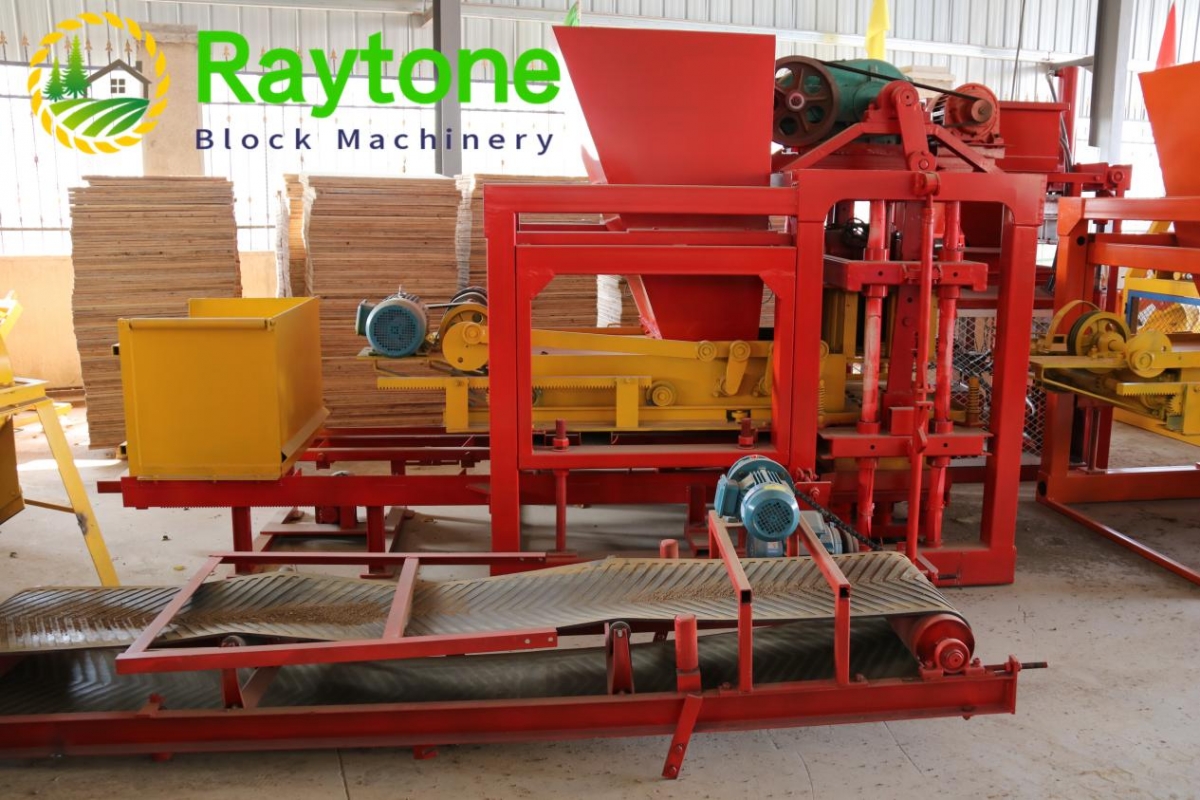

RAYTONE is a leading manufacturer and supplier of block making machines in the construction industry. We specialize in the production and distribution of high-quality block making machines, including manual, automatic, and hydraulic models, catering to the needs of our clients worldwide. Our products not only meet the industry standards but also exceed our customers’ expectations in terms of quality, efficiency, and versatility.

Our block making machines are designed to produce high-quality and uniform blocks, bricks, and pavers for various construction projects. We use premium quality materials and advanced manufacturing techniques in the production of our machines, ensuring excellent performance and longevity. Our manual block making machines are compact and easy to operate, making them suitable for small-scale production. They are ideal for manufacturing traditional clay or concrete bricks, which are widely used for building walls, fences, and pavements.

In addition to our standard machines, we also offer customized solutions to meet the specific requirements of our clients. Our team of experienced engineers and technicians work closely with customers to understand their needs and design tailored solutions that are efficient and cost-effective.

Our block making machines are the perfect solution for your construction needs. Durable and reliable, these machines guarantee consistent and high-quality results every time. Made with top-quality materials and advanced technology, they are designed to withstand heavy use and harsh conditions, making them the dependable choice for all your block making needs. Whether you’re building homes, commercial spaces or roads, our machines will provide you with efficient and precise results, ensuring your projects are completed on time and to the highest standards. Trust in our block making machines for a solid and reliable foundation for your construction projects.

Craftsmanship and technology have often been viewed as opposing forces, with one valuing handiwork and the other prioritizing efficiency. However, in our block machine, we have found the perfect balance between the two. Our machine embodies the principles of traditional craftsmanship, utilizing precision engineering and expert manual labor, while also incorporating cutting-edge technology for enhanced productivity and quality control.

Block making machine, also known as brick making machine, is a device that produces concrete blocks or bricks in various shapes and sizes. It plays an important role in the construction industry by providing a cost-effective and efficient solution for producing building materials. With the advancement of technology and the increasing demand for sustainable building materials, block making machines have evolved to become more versatile and eco-friendly. In this article, we will delve deeper into the functionalities and benefits of block making machines and explore how they have revolutionized the way we build structures.

2.Can a block making machine be used for large-scale production?

3.What is the power source for a block making machine?

4.What quality control measures are in place during the production process of a block making machine?

5.How does the block making machine handle the release of excess water during the curing process?

6.What is the difference between a fully automatic and semi-automatic block making machine?

7.What is the capacity of a block making machine in terms of number of blocks produced per hour?

8.Can the block making machine be operated manually or does it require automation?

9.How does the block making machine handle waste materials?

10.How does the block making machine ensure uniformity in block sizes?

1.How much space is required to set up a block making machine?

The space required to set up a block making machine can vary depending on the size and type of machine. Generally, a small manual machine may only require a few square meters of space, while a larger fully automatic machine may require several hundred square meters. It is recommended to have a dedicated space for the machine, as well as space for raw materials, finished products, and storage. It is best to consult with the manufacturer or supplier of the specific machine for exact space requirements.

2.Can a block making machine be used for large-scale production?

Yes, a block making machine can be used for large-scale production. These machines are designed to produce a high volume of blocks in a short amount of time, making them ideal for large-scale production. They are also highly efficient and can produce consistent and high-quality blocks, making them a cost-effective option for large-scale production. Additionally, many block making machines can be customized to meet the specific needs and requirements of a large-scale production operation.

3.What is the power source for a block making machine?

The power source for a block making machine can vary depending on the type and model of the machine. Some common power sources include electricity, diesel, gasoline, and hydraulic power. Some machines may also be manually operated.

4.What quality control measures are in place during the production process of a block making machine?

1. Raw Material Inspection: The first step in the production process is to inspect the quality of the raw materials used in making the block making machine. This includes checking the dimensions, strength, and durability of materials such as steel, cement, sand, and aggregates.

2. Machine Calibration: Before starting the production process, the block making machine is calibrated to ensure that it is functioning properly and producing blocks of the desired size and shape.

3. Regular Maintenance: The machine is regularly maintained and serviced to ensure that it is in good working condition. This includes checking and replacing any worn-out parts, lubricating moving parts, and cleaning the machine.

4. Quality Control Checks: Throughout the production process, quality control checks are conducted to ensure that the blocks being produced meet the required standards. This includes checking the dimensions, strength, and density of the blocks.

5. Testing of Blocks: Samples of blocks are periodically taken from the production line and tested for strength and durability. This helps to identify any issues with the production process and make necessary adjustments.

6. Operator Training: The operators responsible for running the block making machine are trained on the proper techniques and procedures to ensure consistent quality of the blocks being produced.

7. Documentation and Record Keeping: All quality control checks and test results are documented and kept for future reference. This helps to track any issues that may arise and make improvements to the production process.

8. Quality Management System: Many block making machine manufacturers have a quality management system in place to ensure that all processes and procedures are followed correctly and consistently.

9. Third-Party Inspections: Some manufacturers may also have third-party inspections to verify the quality of their products and ensure that they meet industry standards.

10. Customer Feedback: Customer feedback is also an important aspect of quality control. Manufacturers may gather feedback from customers to identify any issues and make necessary improvements to their production process.

5.How does the block making machine handle the release of excess water during the curing process?

The block making machine does not handle the release of excess water during the curing process. This is typically done manually by the operator or through the use of a curing chamber or curing racks. The excess water is released by removing the blocks from the molds and allowing them to air dry or by placing them in a curing chamber where the temperature and humidity can be controlled to facilitate the curing process. Some block making machines may have built-in curing chambers or racks to aid in this process, but it is not a function of the machine itself.

6.What is the difference between a fully automatic and semi-automatic block making machine?

A fully automatic block making machine is a machine that can operate without any human intervention. It can automatically mix, mold, and stack the blocks without the need for manual labor. It is equipped with advanced technology and sensors that can control the entire process.

On the other hand, a semi-automatic block making machine requires some level of human intervention. It can perform some tasks automatically, such as mixing and molding, but it still requires manual labor for other tasks, such as stacking the blocks. It is less advanced and relies on manual control for certain functions.

7.What is the capacity of a block making machine in terms of number of blocks produced per hour?

The capacity of a block making machine can vary depending on the size and type of machine, as well as the skill and efficiency of the operator. However, on average, a block making machine can produce anywhere from 500 to 2000 blocks per hour. Some high-end machines can even produce up to 4000 blocks per hour.

8.Can the block making machine be operated manually or does it require automation?

The block making machine can be operated manually, but it is more commonly operated with automation. Automation allows for faster and more efficient production, as well as reducing the physical labor required. However, some smaller or simpler block making machines may still be operated manually.

9.How does the block making machine handle waste materials?

The block making machine handles waste materials by incorporating them into the production process to create new blocks. This process is known as waste utilization or recycling. The machine crushes and mixes the waste materials with other raw materials such as cement, sand, and water to form a new mixture. This mixture is then compressed and molded into blocks using the machine’s molds and hydraulic pressure.

The waste materials that can be used in this process include construction and demolition waste, fly ash, slag, and other industrial by-products. These materials are crushed and sieved to remove any impurities before being added to the mixture.

The block making machine can also handle plastic waste by melting it and mixing it with the raw materials to create plastic blocks. This process not only reduces waste but also helps in reducing the use of natural resources such as sand and gravel.

The machine also has the capability to handle organic waste such as rice husks, sawdust, and other agricultural waste. These materials are added to the mixture to improve the strength and insulation properties of the blocks.

Overall, the block making machine plays a crucial role in handling waste materials by converting them into useful and sustainable building blocks. This not only helps in reducing waste but also contributes to a more environmentally friendly construction industry.

10.How does the block making machine ensure uniformity in block sizes?

1. Precise Mould Design: The block making machine is designed with precision to ensure that the moulds used for making blocks are of the same size and shape. This ensures that all the blocks produced are uniform in size.

2. Consistent Pressure: The machine applies consistent pressure on the raw materials used for making blocks. This ensures that the blocks are compacted evenly, resulting in uniform size and density.

3. Vibration System: The block making machine is equipped with a vibration system that helps to evenly distribute the raw materials in the mould. This ensures that the blocks are of the same size and density.

4. Accurate Feeding System: The machine has an accurate feeding system that ensures the right amount of raw materials is fed into the mould. This helps to avoid variations in block sizes.

5. Quality Control: Most block making machines have a quality control system that checks the size and shape of the blocks produced. If any variations are detected, the machine automatically adjusts to ensure uniformity.

6. Regular Maintenance: Regular maintenance of the machine is essential to ensure that all its components are functioning properly. This helps to avoid any issues that may affect the uniformity of block sizes.

7. Skilled Operators: Skilled operators are trained to operate the block making machine and ensure that all the processes are carried out correctly. This helps to maintain uniformity in block sizes.

8. Standardized Raw Materials: The use of standardized raw materials, such as cement, sand, and aggregates, also contributes to the uniformity of block sizes. This ensures that the blocks produced have the same strength and density.