- 08

- 5月

Application of Automatic Block Machine

In today’s construction industry, the use of automatic block machine has revolutionized the way buildings are constructed. These machines, also known as concrete block making machines, are capable of producing thousands of high-quality building blocks in a short period of time. This has greatly increased the efficiency and productivity of the construction process.

RAYTONE is a leading company in the manufacturing and distribution of block machines. Our machines have been used in various applications, providing high-quality and efficient solutions for the construction industry. In this article, we will discuss the many applications of automatic block machines and how they have revolutionized the construction process.

What is Automatic Block Machine?

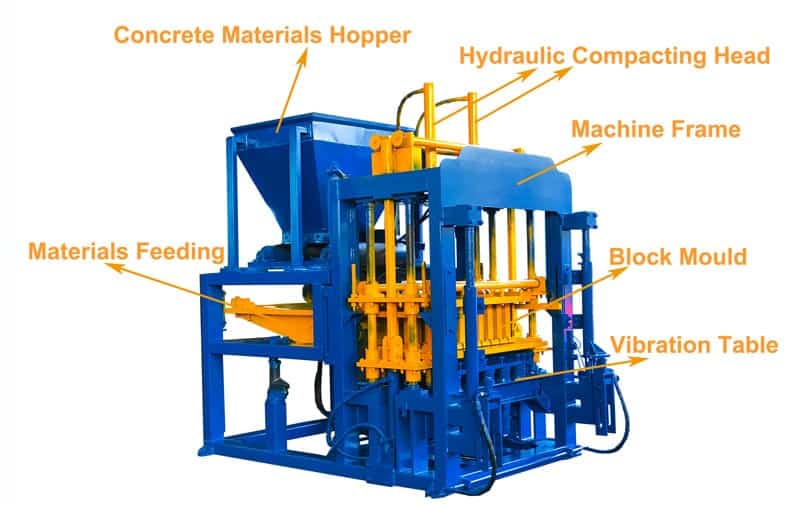

Automatic block machines are machines that are used to produce concrete blocks automatically. They typically use a combination of hydraulic pressure and vibrating plates to compact the concrete mixture into the desired shape and size. These machines are known for their high efficiency and accuracy in producing uniform and high-quality blocks. They can be programmed to produce a wide range of block shapes and sizes, making them versatile for various construction projects. Some automatic block machines also have the capability to add colorants or other additives to the concrete mixture, allowing for the production of colored or textured blocks.

Related series:

Application of Automatic Block Machine:

The automatic block machine is typically used in the infrastructure development,road and pavement construction,landscaping and hardscaping,building and housing projects,industrial construction,commercial building construction,retaining walls,etc.

Infrastructure Development:

A strong infrastructure is the backbone of any nation’s development. With the help of automatic block machines, the construction of roads, bridges, and tunnels has become faster and more efficient. Our machines produce high-quality blocks that are essential for building durable and long-lasting infrastructure.

Road and Pavement Construction:

They are also widely used in road and pavement construction. They can produce different types of blocks, such as interlocking blocks, which are ideal for road construction. Interlocking blocks create a strong and stable pavement, reducing the need for constant maintenance.

Landscaping and Hardscaping:

Landscaping and hardscaping are important aspects of beautifying any outdoor space. With the use of it, landscaping and hardscaping projects have become more efficient and cost-effective. The precision and versatility of our machines allow for the creation of different block shapes and sizes, fulfilling the unique design requirements of each project.

Building and Housing Projects:

One of the primary applications of automatic block machines is in the construction of buildings and houses. These machines can produce different types of blocks, including load-bearing blocks, which are essential for constructing walls and columns.

Industrial Construction:

They are also used in the construction of industrial facilities such as factories and warehouses. These machines produce high-quality blocks that can withstand heavy loads, making them ideal for industrial construction.

Commercial Building Construction:

The use of they has also revolutionized the construction of commercial buildings such as shopping malls, office buildings, and hotels. These machines produce high-quality blocks that are essential for constructing strong and durable structures. With the use of automatic block machines, commercial construction projects can be completed in a shorter time, allowing for faster occupancy and return on investment.

retaining walls:

It is also used in the production of blocks for retaining walls, which are often used to prevent soil erosion or to create level surfaces for buildings. Again, the precision and uniformity of the blocks produced by the machine make them highly suitable for this application.

Other:

In addition to these applications, it can also be used in the production of decorative blocks for landscaping purposes. These blocks can be produced in a variety of colors, sizes, and patterns, making them a popular choice for beautifying outdoor spaces.

In conclusion, the applications of they are vast and have greatly contributed to the development of modern infrastructure and construction. RAYTONE is committed to providing high-quality and efficient automatic block machines for various construction projects, making the construction process faster, cost-effective, and sustainable. With our state-of-the-art technology and expertise, we are proud to be a part of the infrastructure and construction development of nations globally.

Friendly reminder:

Ⅰ Always read the manufacturer’s instructions and follow them carefully. This will ensure proper functioning and prolong the lifespan of the machine.

Ⅱ Before using the automatic block machine, check all its components to make sure they are clean and in good working condition. This includes checking the mold, motor, gearbox, and other important parts.

Ⅲ Make sure the machine is properly lubricated. This will help reduce the friction between moving parts and ensure smooth operation.

Ⅳ Pay attention to the type and size of materials to be used in the machine. Using the wrong materials can cause damage and affect the quality of the bricks produced.

Ⅴ Make sure that the machine is placed on a flat and stable surface to prevent it from tipping over during operation.

Ⅵ Never overload the machine. It is important to carefully follow the recommended capacity for each type of material to prevent damage to the machine.

Ⅶ Regularly clean the machine after use to prevent any buildup of materials that could affect its performance.

Ⅷ If any issues arise, stop using the machine immediately and consult a professional for assistance. Do not attempt to fix the machine on your own as it may lead to further damage.