- 04

- 7月

Automatic Block Machine vs Block Making Machine: Key Differences Explained

Introduction

The construction industry continually evolves, embracing advanced technologies to improve efficiency, cost performance, and overall quality. Among the pivotal innovations are block machines, essential for producing concrete blocks used in various construction projects. RAYTONE, a leading manufacturer in China, offers two main types of block machines: the automatic block machine and the traditional block making machine. This article delves into the key differences between these two machines, exploring their features, advantages, and suitable applications.

Understanding Block Machines

Block Making Machine

Traditional block making machines are semi-automatic or manual machines designed to produce concrete blocks. They are widely used in small to medium-sized projects where high volume and speed are not critical. These machines require significant human intervention for operations such as feeding raw materials, operating controls, and removing finished blocks.

Automatic Block Machine

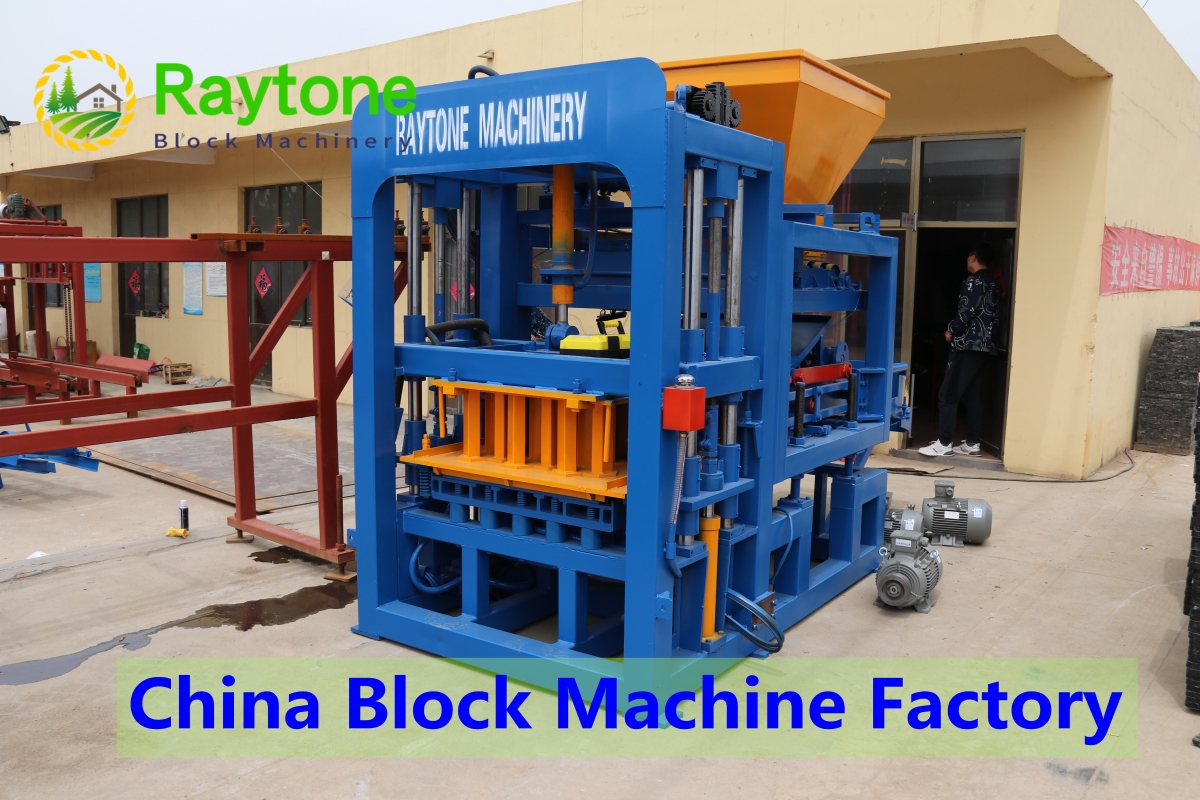

In contrast, automatic block machines represent the pinnacle of modern manufacturing technology. These machines automate the entire block production process, from raw material feeding to block molding and removal. Automatic block machines are ideal for large-scale projects where high efficiency, consistency, and minimal human intervention are paramount.

Key Differences Explained

Automation Level

The primary difference between automatic block machines and traditional block making machines lies in their level of automation. Automatic block machines are designed to perform all operations automatically. They are equipped with advanced control systems that manage the entire production process, significantly reducing the need for manual labor. This automation ensures higher production rates, consistent quality, and reduced labor costs.

On the other hand, traditional block making machines require manual input at various stages of production. Operators need to load raw materials, control the machine, and handle the finished blocks. While these machines are less expensive initially, the manual labor required can result in higher operational costs over time.

Production Capacity and Speed

Automatic block machines offer superior production capacity and speed compared to traditional block making machines. Due to their automated processes, they can produce a higher number of blocks per hour, making them suitable for large-scale manufacturing. For instance, RAYTONE’s automatic block machines can produce thousands of blocks daily, meeting the demands of large construction projects efficiently.

Traditional block making machines have lower production rates due to the manual operations involved. They are more suitable for smaller projects or for businesses that do not require high-volume production. The slower production speed can also affect project timelines, making them less ideal for time-sensitive projects.

Consistency and Quality

Consistency in block quality is another significant advantage of automatic block machines. The automated systems ensure precise mixing, molding, and curing processes, resulting in uniform blocks with consistent dimensions and strength. This uniformity is crucial for construction projects that demand high-quality standards and precision.

In traditional block making machines, the quality of blocks can vary due to human error and inconsistencies in manual operations. Factors such as incorrect mixing ratios, improper molding pressure, and uneven curing can lead to variations in block quality. These inconsistencies can affect the structural integrity and appearance of the final construction.

Labor and Operational Costs

While the initial investment for an automatic block machine is higher, it offers long-term cost advantages. The reduction in manual labor leads to lower operational costs, as fewer workers are needed to operate the machine. Additionally, the higher production rates and consistency in quality can result in faster project completion and fewer defects, further reducing costs.

Traditional block making machines, though cheaper initially, require more labor to operate, leading to higher labor costs over time. The slower production rates can also increase project timelines, potentially raising overall project costs.

Advanced Features

Automatic block machines are equipped with advanced features such as computerized control systems, automatic feeding systems, and automated block removal mechanisms. These features enhance the efficiency and accuracy of the production process. RAYTONE’s automatic block machines, for instance, incorporate state-of-the-art technology to ensure optimal performance and minimal downtime.

Traditional block making machines are simpler in design and lack these advanced features. While they are easier to operate and maintain, they do not offer the same level of efficiency and precision as automatic machines.

Applications

Automatic block machines are ideal for large construction companies, contractors, and block manufacturers who require high-volume production and consistent quality. They are suitable for projects such as large-scale residential developments, commercial buildings, and infrastructure projects.

Traditional block making machines are more suited for small to medium-sized construction projects, local contractors, and businesses with lower production requirements. They are ideal for small residential projects, rural construction, and businesses looking to enter the block manufacturing market with a lower initial investment.

Conclusion

Choosing between an automatic block machine and a traditional block making machine depends on various factors such as project scale, budget, and production requirements. RAYTONE, a leading manufacturer in China, offers a range of block machines to suit different needs, ensuring high-quality, efficient, and cost-effective solutions for the construction industry.

Automatic block machines provide significant advantages in terms of automation, production capacity, consistency, and long-term cost performance, making them ideal for large-scale projects. Traditional block making machines, while less automated, offer flexibility and lower initial costs, making them suitable for smaller projects and businesses with limited budgets. By understanding the key differences and benefits of each type, businesses can make informed decisions to meet their specific needs and achieve optimal results in their construction projects.