- 21

- May

TYPES OF GMT PALLET FOR CONCRETE BLOCK MAKING MACHINE

GMT BRICK PALLET TECHNICAL DATA and TYPES

GMT(Glass Mat reinforced Thermoplastics), or glass fiber mat reinforced thermoplastic composite material, which is made of fiber as reinforcing material and thermoplastic resin as base material made by method of heating and pressurizing. The pressing process is made by the 3000 Ton pressure machines. Its density is 1200kg/cubic meters; its life can be 8 years, some can reach 10 years; now it is the most widely used among these brick pallets because cheaper cost and environmental, longer life, water-resistant, temperature resistance, less weight, can not be replaced by traditional pallets;

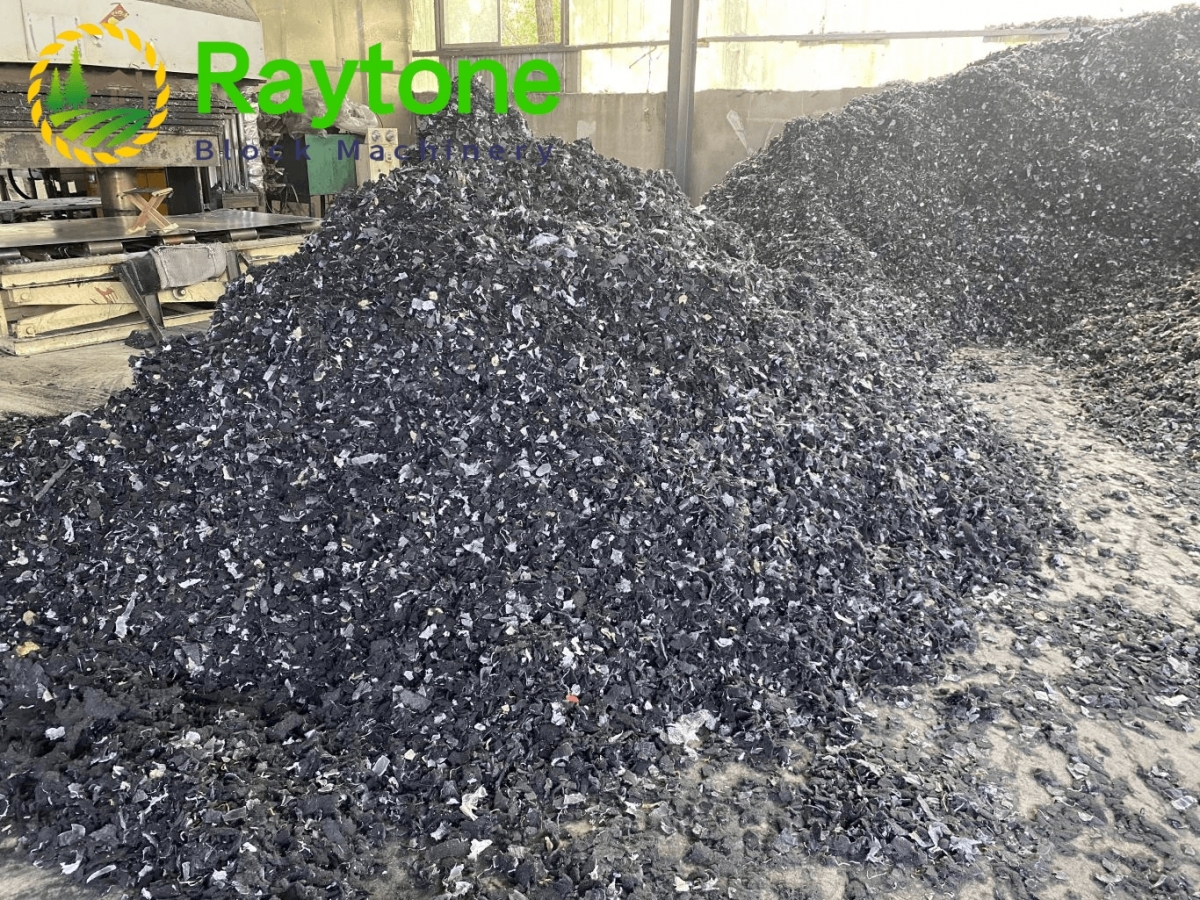

1.Raw materials of GMT Brick pallet

The raw materials of GMT brick pallet is from the leftovers which is used for automobile inner decoration materials like the interior ceiling, the PE (polythene) foot mat, the car seating suites,etc. They are not recycled from used materials but leftovers for the new car inner decorations, These materials are including a lot glass fiber, fiber, also adhesive, the following are raw materials photos:

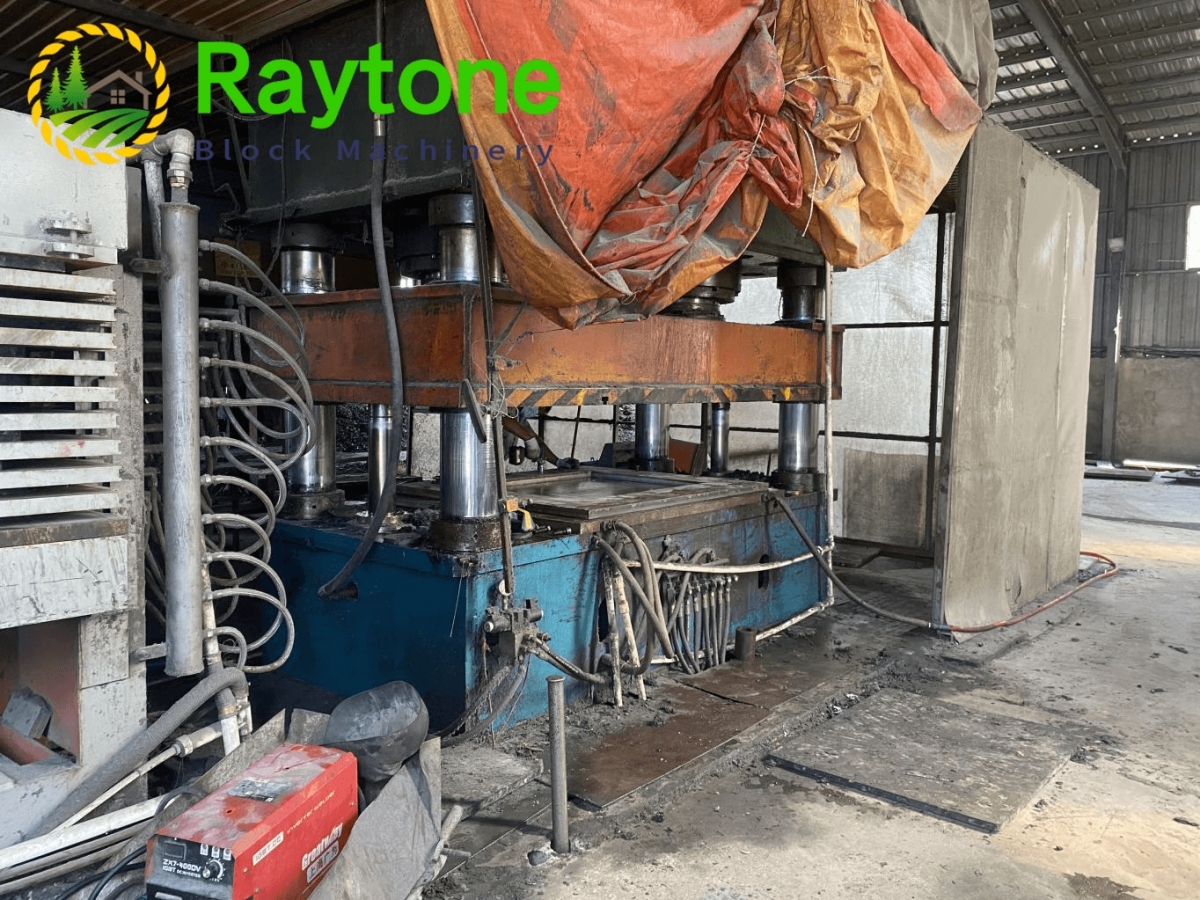

2.GMT Brick pallet forming process

The GMT brick pallet raw materials of car interior decoration materials are teared into small piece by shredding machine. Then these teared materials will be weighed by certain weight accurately for different size brick pallets, and add other certain strong glue materials into it. Next step, the weighed materials will be wrapped into a soft but thick plastic tarpaulin to be heated to high temperature under heating machine, after several minutes, the heated materials are taken out and put onto the customized size mould on the pressing machine, after it is being pressed for 5 minutes under 3000 tons pressure, it will be taken out, and remove some retails on the pallets, then put it on the cold pressing machine to make it cold and more flat, now the final GMT brick pallets come out.

3.GMT brick pallet Technical Parameters

| Test Items | Test Result | Length and Width Deviation | ±2mm |

| Density | 1200kg/cubic meters | Thickness deviation | ±1mm |

| Water Immersion Rate | ≤0.5% | Impact Strength | ≥12MJ/m2 |

| Surface hardness | ≥65HD | Shore Hardness | ≥70d |

| Impact Strength | ≥ 20KJ/m2 | aging | 8-10 years |

| Flexural Strength | ≥30MPa | Temperature resistance | -40°C to 90°C, |

| Flexural Modulus | ≥2.0MPa |

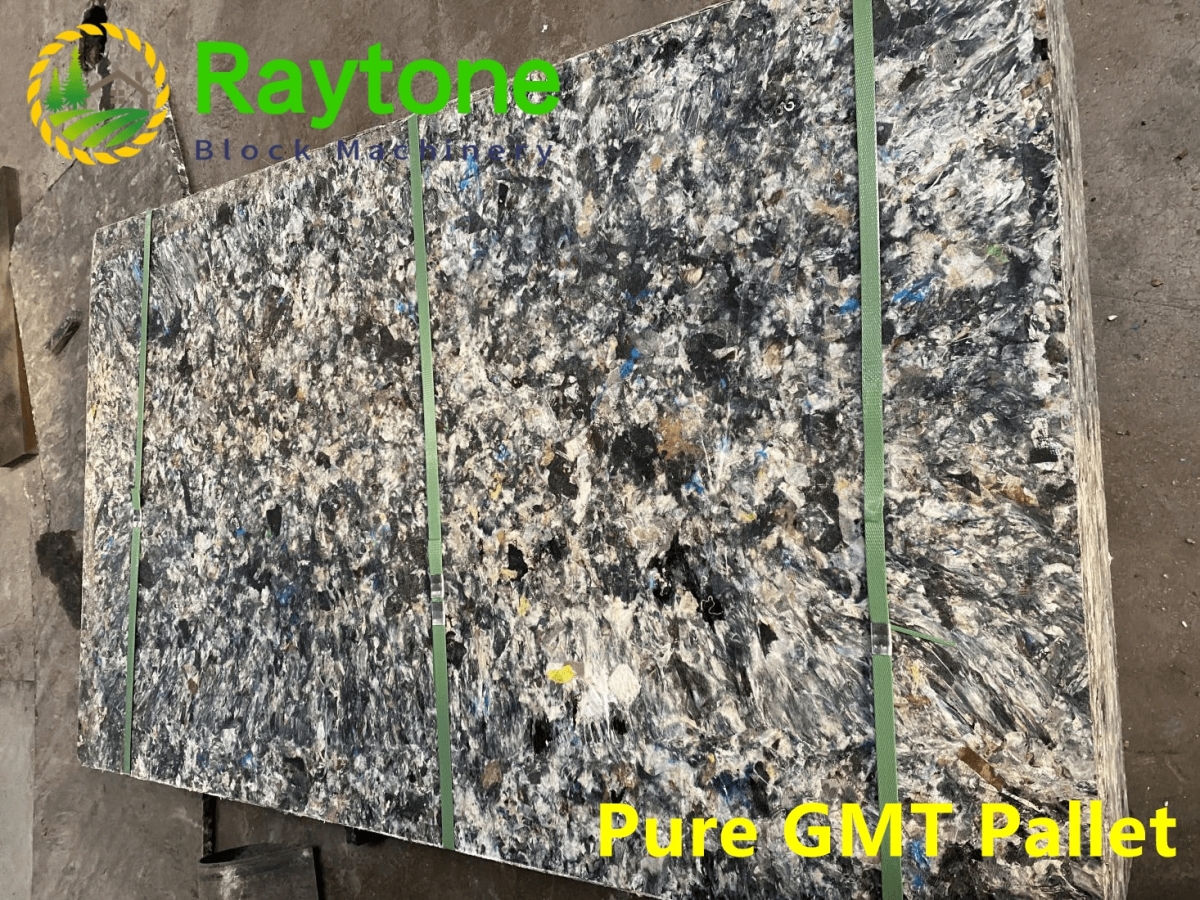

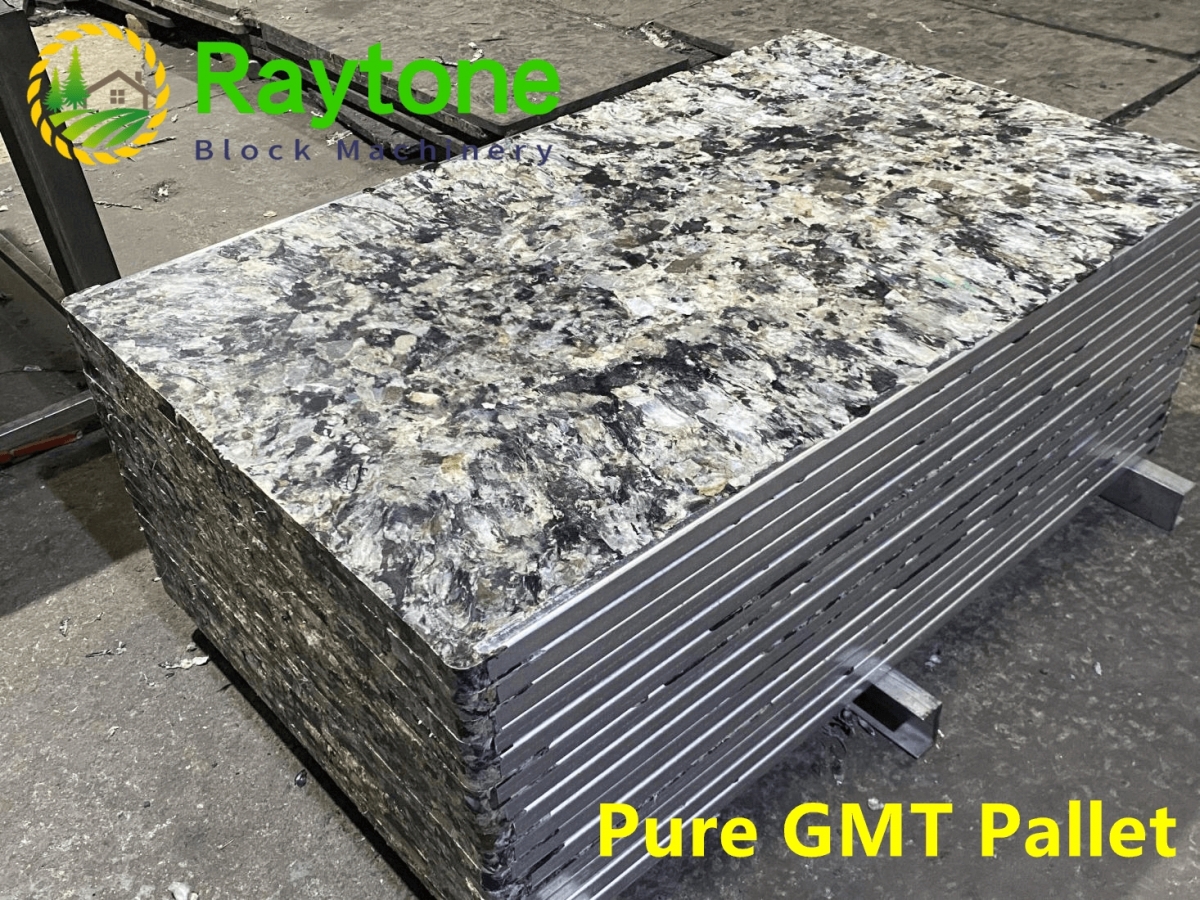

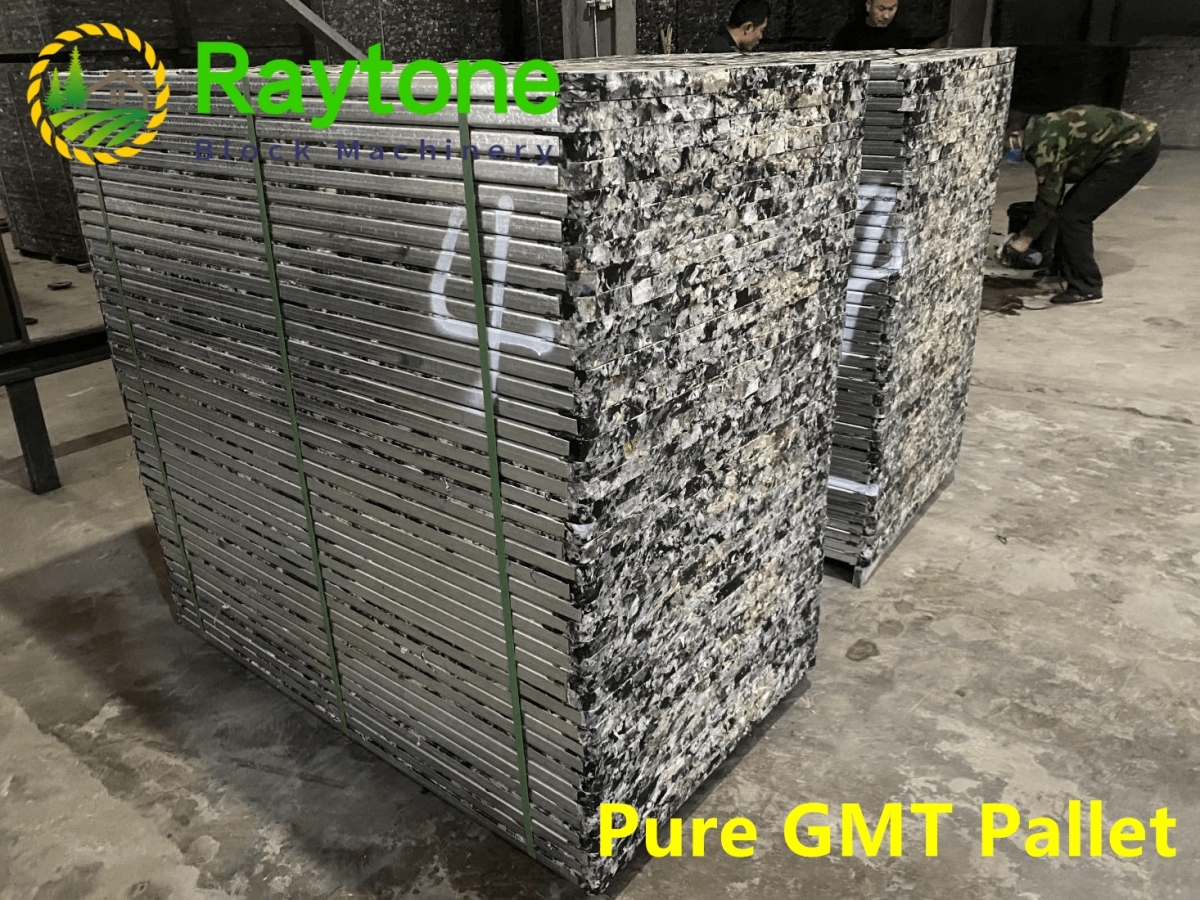

4.Photos of Pure GMT Brick pallet

(1)Pure GMT Brick Pallet

(2) Pure GMT pallet with 3mm galvanized steel channel; this kind pallet can be used for steam curing purpose;

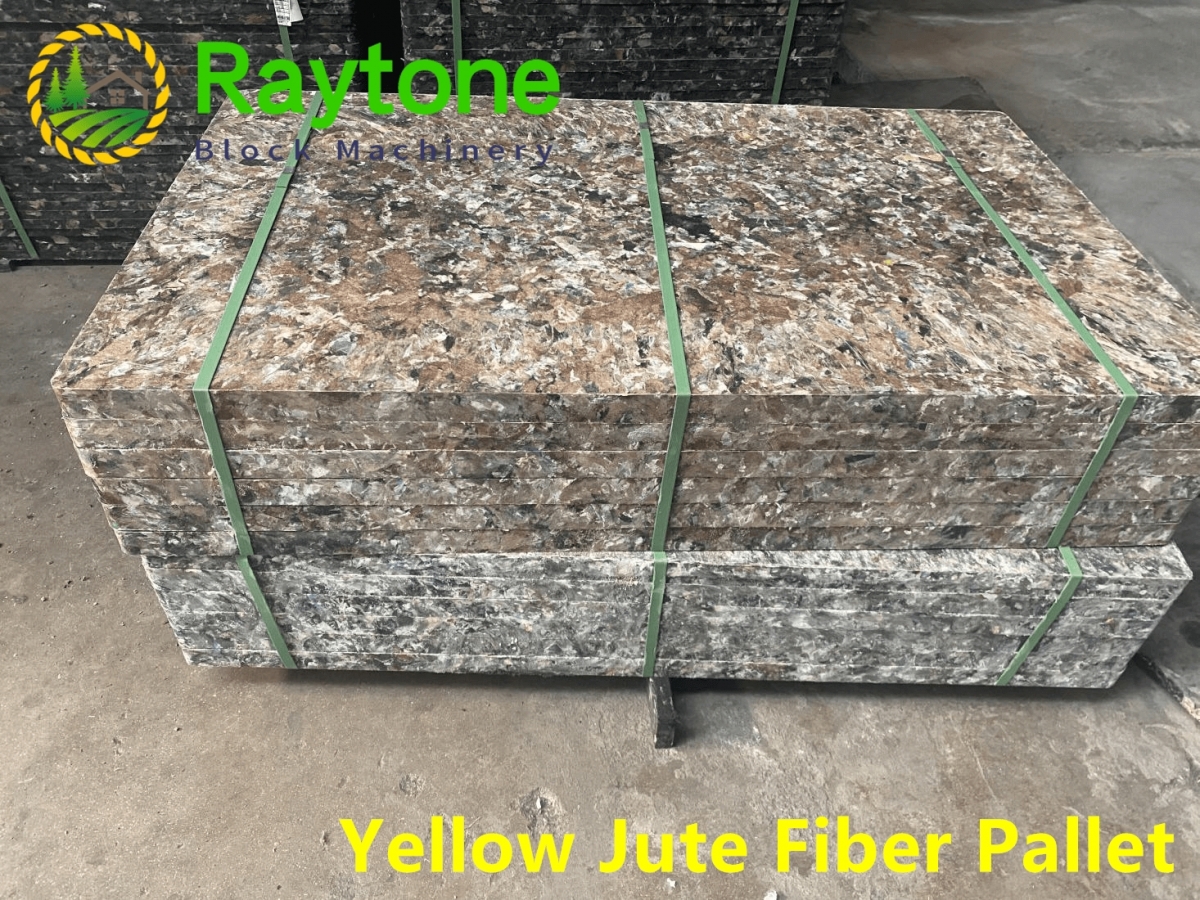

(3) Jute Yellow model GMT Fiber Brick Pallet; this type brick pallet density is 1100kg per cubic meters; hardness is also very good.

The follow photo is the testing of 1400*840*42mm yellow GMT brick pallet for 690KG, the pallet is bent 6mm; so this pallet quality is also very good, because it is a little cheaper cost, so it is good for small size brick pallet;

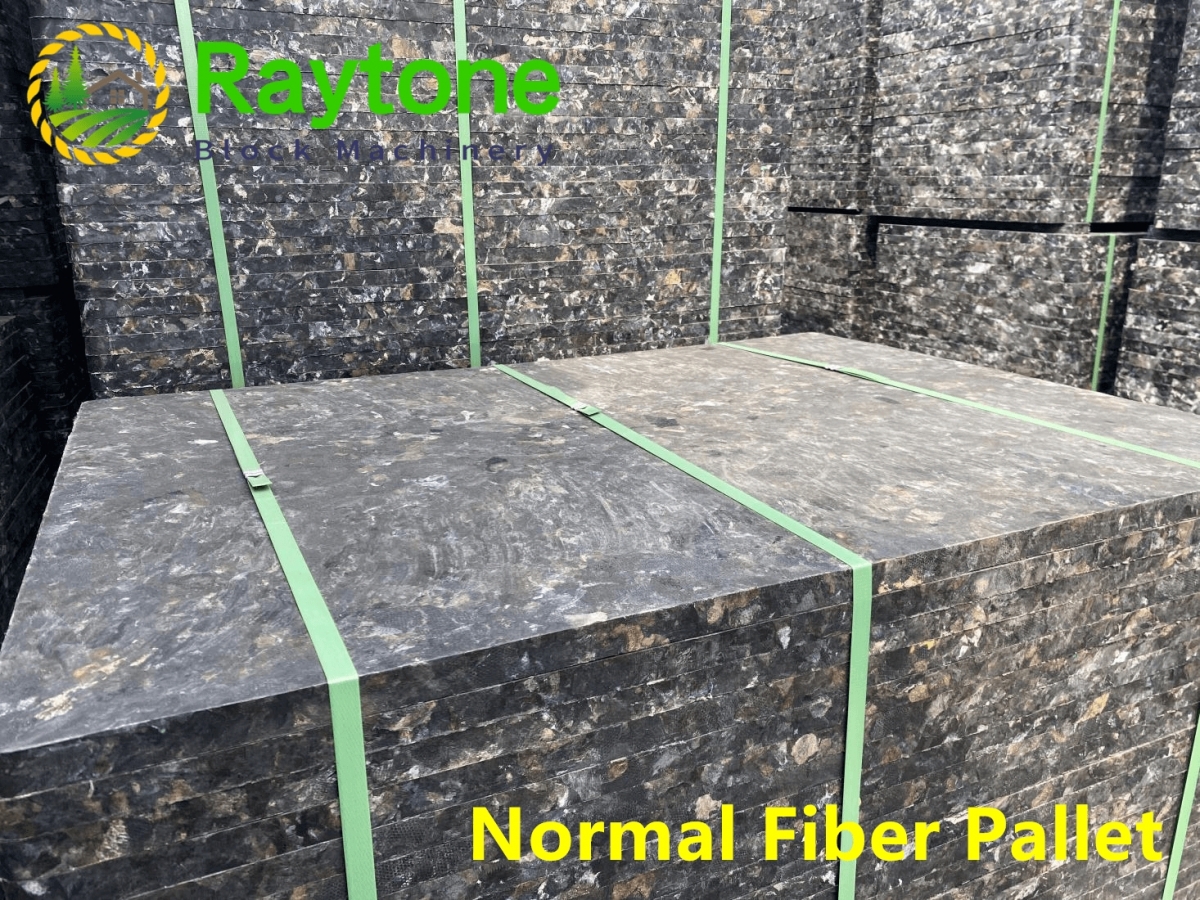

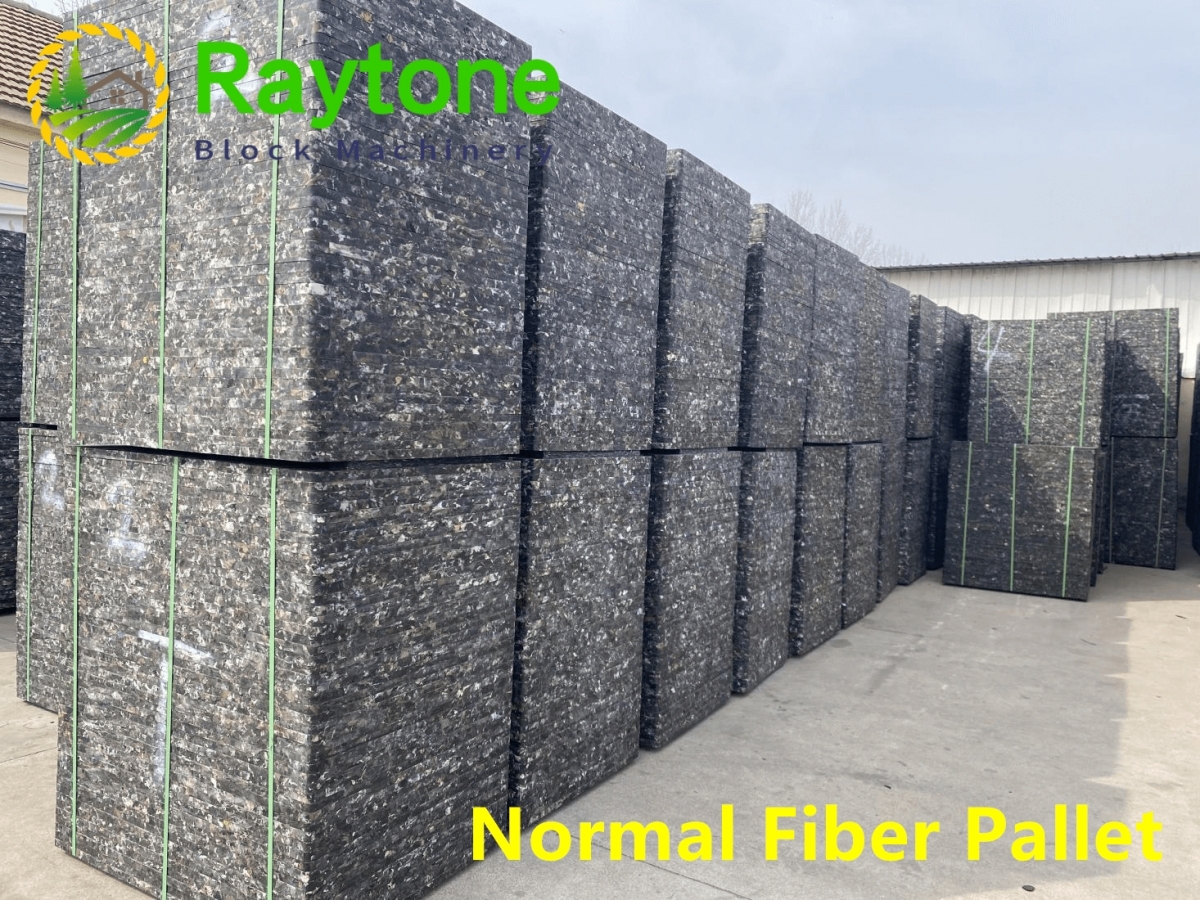

(4) Fiber pallet for block machine

This kind of fiber brick pallet is containing 70-80% normal fibers, and we also add some yellow type fibers and 10% white glass fiber to increase its hardness, so even this normal fiber brick pallet , it is also good performance , life can reach 6 -8 years; the fiber brick pallet is mainly for small sizes pallets for block machine, but also some buyer choose this one for big size pallet for big block machine, because of its cheap price.

5.The advantages of GMT brick pallet for block factory purpose;

(1)Protect environment, because it is using the leftovers, it is friendly to human environment. so it helps earth to reuse the materials to save industry waste; on this side saying, it is better than PVC brick pallet, Bamboo brick pallet, also wooden brick pallets.

(2), from the life, GMT pallet can reach around 8-10 years life, while PVC is normally has 6 years, Bamboo have 4 years life, wooden pallet only 2 year life.

(3), from the cost, PVC is the most expensive; Bamboo is slightly more cost than GMT brick pallets, so the GMT is the best cost to performance among all these brick pallets;

6.How to Choose the right GMT brick pallets for your brick factory:

Different raw materials are with different cost, because different materials has a little difference on their performance. So the GMT brick pallets price is based on its raw materials and different materials containing percentage.

the key factors of GMT block pallet is their glass fiber content percentage, the more glass fiber content, its hardness is higher, performance is better,

There are some cheap black color fiber pallets in the market also ,they have rough surface, not the first level brick pallet, RAYTONE COMPANY promise only sell the best quality GMT brick pallet to our clients, do the business for long-term;

7.GMT brick pallets Comparing with other types brick pallet

| Item | Life | Hardness | Surface Smooth | Density | Cost |

| GMT Brick Pallet | 8-10 years | Good | good | 1200KG/CBM | Good cost to performance |

| PVC Brick pallet | 6 years | Good | Very good | 1800KG/CBM (Heavy, not friendly for shipping cost) | Expensive |

| Bamboo Brick pallet | 4 years | good | normal | 1050KG/CBM | Higher than GMT pallet |